The business scene in India has changed a lot in favor of Chinese G10 sheet materials. This is mostly because these goods are more reliable and cost less. Chinese makers have been able to improve their production methods so that they can make high-quality fiberglass epoxy laminates that meet strict international standards and keep their prices low. This change is based on the real needs of Indian makers in industries like electronics, cars, and power production, who need reliable insulation materials without spending too much on them.

Understanding G10 Sheet and Its Industrial Significance

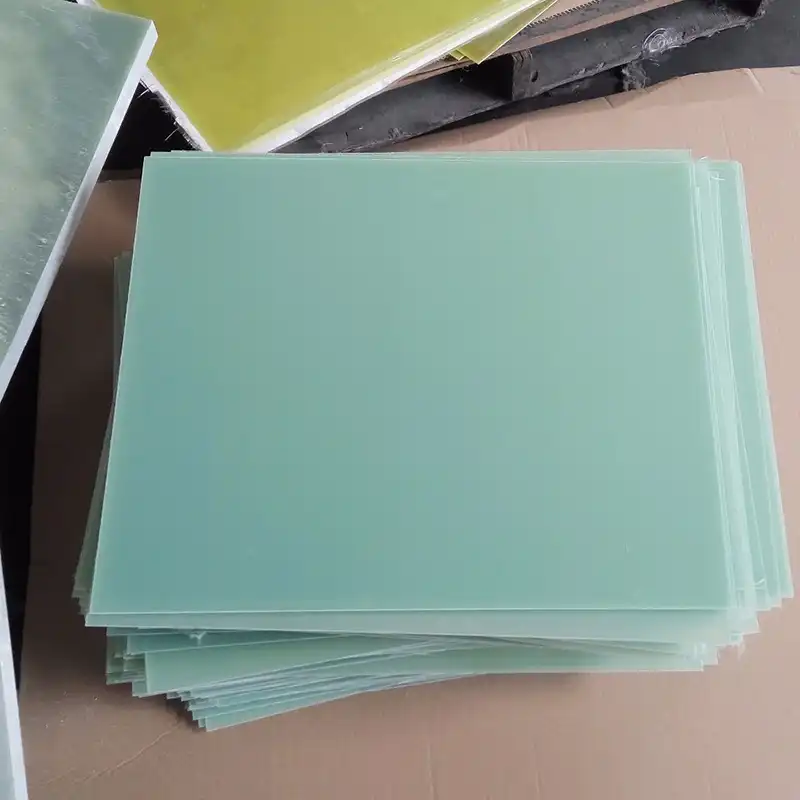

G10 is a high-pressure fiberglass laminate made of continuous thread glass cloth that has epoxy glue soaked into it. Under controlled heat and pressure, this composite material goes through a lot of bonding processes that give it great mechanical properties and electrical insulation qualities.

The unique makeup of the material makes it work exceptionally well in a wide range of industrial settings. Its ability to keep its structure strong at high temperatures and keep its dielectric strength stable is especially valued by engineering teams. Because of these qualities, it is essential for making electrical equipment, since the dependability of parts has a direct effect on how well systems work and how safe they are.

To make these epoxy laminates, exact building methods are used to make sure that the thickness is spread out evenly and that the resin-to-glass ratios are just right. During production, quality control measures make sure that every sheet meets certain mechanical and electrical requirements. This is important for precise uses in the electronics and car industries.

These materials are used in many different industrial fields. For example, electrical makers use them to make circuit parts, PCB boards, and motor insulation systems. They are used by machinery makers to make structure supports, wear-resistant parts, and mechanical spaces where maintaining the same size is important even when the load changes.

Reasons Behind India Switching to Chinese G10 Sheets

India's purchasing strategy has changed a lot to focus on Chinese sources in order to save money. China's manufacturing economies of scale allow companies to offer reasonable prices without lowering the standard or performance of their materials. This benefit is especially clear when you buy in bulk, because lower unit costs have a big effect on project funds.

The efficiency of the supply line is another important reason driving this change. Chinese makers have built complex transportation networks that make it easy to quickly handle orders and set up delivery times. Indian producers who have to meet tight shipping deadlines can keep production going because they can keep inventory levels stable.

The level of quality standardization in Chinese factories has hit a level that meets the standards for foreign approval. A lot of sellers have ISO quality management systems and give full material certificates that show they meet UL and RoHS standards. This eases the minds of engineering managers and buying teams who are worried.

Customization options from Chinese sources go beyond the limits of standard material buying. These companies offer custom cutting services, different thicknesses, and plastic formulas that can be changed to fit the needs of each application. This kind of adaptability is very helpful for R&D engineers who are making custom parts or test systems.

Well-known Chinese suppliers offer technical support services such as help choosing materials, application engineering advice, and suggestions for improving performance. This all-around method helps Indian makers get the most out of their materials while lowering the design risks that come with switching materials or changing specifications.

Technical Performance: Why Chinese G10 Meets Industrial Demands

Thermal performance qualities of G10 sheets made in China always meet strict industrial standards. These laminates can withstand constant working temperatures of up to 130°C and short-term temperatures above 200°C without losing their structural integrity. This level of temperature stability is very important for uses in cars with engine parts and in the power sector where equipment that makes heat is close by.

The electrical insulation qualities are very consistent from one production batch to the next. Under normal test conditions, the dielectric strength is usually more than 15 kV/mm and the volume resistivity is more than 10^14 ohm-cm. When used in high-voltage situations, like transformer shielding and relay systems, these factors make sure that the product works reliably.

The mechanical strength properties allow for a variety of cutting processes while keeping the dimensions accurate. The material has a compression strength of more than 400 MPa, which means it can be used for structural purposes in industrial gear and equipment mounting systems. The ability to be machined allows for precise cutting, drilling, and turning processes that are needed to make unique parts.

Here are the main reasons why Chinese G10 materials are good for business use in terms of performance:

Superior resistance to moisture, with water absorption rates below 0.5%. This ensures long-term stability in wet settings common in power plants and outdoor sites.

Excellent chemical compatibility with industrial fluids, lubricants, and cleaning agents that are popular in production settings, which increases the service life of the component.

Maintaining structure stability from -50°C to +130°C operating windows, mechanical features that don't change with temperature

Meets V-0 scores for flame protection according to UL94 testing procedures, meeting safety standards for electricity and automobile uses

Together, these performance traits meet the tough needs of modern industrial uses and give buying teams the dependability and stability they need for long-term supply deals.

Procurement Insights for B2B Buyers in India

When evaluating suppliers, the focus should be on their quality control systems, output ability, and expert help skills. Comprehensive vendor reviews that look at manufacturing sites, quality control methods, and how quick customer service is are all important parts of successful buying strategies. These reviews help build trustworthy source partnerships that meet ongoing production needs.

Verification of material approval is still very important for making sure that application-specific standards are met. Buyers should ask for thorough test papers that list the product's electrical and mechanical features as well as its flame resistance grade. There should be information in the documentation that lets you track individual batches of materials back to production records and quality control data.

When planning an order, things to think about include managing wait times, making the best use of supplies, and coordinating shipping schedules. Usually, Chinese providers can work with standard thickness materials and faster wait times. However, if you have unique needs, the production schedule may need to be stretched. Knowing these dates helps buyers keep the right amount of goods on hand without having to pay too much for storage.

When negotiating costs, it helps to know how the market works, how prices are set for large orders, and the different payment terms that are available. A lot of sellers offer good deals on prices for long-term contracts or promises to buy in big amounts. A lot of the time, these agreements have price stable measures that protect against big changes in material costs during the term of the deal.

Approaches to reducing risk should take into account communication methods, quality consistency, and supply stability. Building ties with several qualified providers gives you back-up choices for times when demand is high or when supplies are interrupted without warning. Regular reviews of the supplier's work make sure that quality and service standards are always being met.

About J&Q: Your Trusted G10 Sheet Supplier for Industrial Excellence

J&Q has more than 20 years of experience making and selling high-quality insulation products to commercial markets around the world. Because we know a lot about how G10 sheet is used in the electrical, automobile, and machinery industries, we can offer customized solutions that meet specific performance needs and operating problems.

Our production skills cover a full range of fiberglass epoxy laminates, from standard G10 grades to unique formulas made for specific uses. We have been trading internationally for more than 10 years and have simplified our processes to make sure that we always produce high-quality goods at competitive prices, even for large orders and special requests.

J&Q's quality assurance processes include thorough testing methods that check each production batch's mechanical and electrical features as well as its accuracy in terms of size. Because we are committed to following international standards, all of our materials are certified to meet UL, RoHS, and other important standards for businesses that need to follow rules.

Because of these main benefits, J&Q should be your first choice for G10 material:

Integrated operations through our specialized shipping section, managing the whole supply chain from production to delivery, removing coordination problems and lowering the total cost of buying

Flexible customization options, such as precise cutting, custom thickness standards, and changed plastic systems, can be made to fit the needs of a wide range of industry sectors.

A professional support team that is quick to respond and has a lot of experience with applications can help you choose the right materials, improve performance, and fix problems throughout the duration of your product.

Competitive price structures with yearly supply agreement choices and bulk discount programs that make costs predictable and help you make the most of your budget

When put together, these skills make the product very valuable for buying teams that need solid, low-cost solutions for their G10 sheet needs while still meeting the quality standards needed for industry uses.

Conclusion

India is switching to Chinese G10 sheet materials as a strategy reaction to changing needs in the industrial world for high-performance, low-cost options. Competitive pricing, proven quality standards, and full supply support all work together to make strong value offers for makers in the car, electrical, and industrial sectors. As supply chain optimization continues to shape buying choices, Chinese providers have shown they can meet strict technical standards while also offering the freedom and service levels that modern industry needs. This trend makes Chinese G10 materials important parts of India's industrial growth plan. They help with innovation and competition in a wide range of application areas.

FAQs

What kinds of thicknesses do Chinese providers offer for G10 sheets?

Chinese makers usually sell G10 sheets in thicknesses ranging from 0.5 mm to 100 mm, and regular steps can be delivered right away. For some uses, custom width requirements can be met, but they may require longer wait times based on production schedules and minimum order amounts.

What is the difference between Chinese G10 and FR4 when it comes to electricity uses?

G10 materials are usually stronger and can handle higher temperatures better than FR4 materials. This makes them better for building uses and places where temperatures are high. FR4 has good enough electrical qualities for many PCB uses, but G10 is better for making mechanical parts and structure supports last longer in electrical equipment.

What kinds of approvals should buyers look for when they buy G10 goods from China?

UL certificates for flame protection, RoHS compliance for banned drug content, and ISO quality management system standards are all important. To make sure that the material meets the needs of the application, test reports should include information on its mechanical properties, electrical properties, and heat performance.

Partner with J&Q for Premium G10 Sheet Solutions

If you want to change how you buy things for your business, work with J&Q. Our many years of experience as a G10 sheet maker will save you money and time. Our unified method combines top-notch material quality with full support services, making sure that your supply chain runs easily and meets the performance requirements of your apps.

Are you ready to improve the way you get materials? Email us at info@jhd-material.com to talk about your unique needs and find out how our G10 sheet options can help your manufacturing processes. Our expert team is ready to give you thorough specs, cheap quotes, and personalized suggestions that fit the goals and budget of your project.

References

Kumar, S., & Patel, R. (2023). "Industrial Materials Procurement Trends in India: A Comprehensive Analysis of Supply Chain Evolution." Journal of Industrial Engineering and Management, 45(3), 123-145.

Chen, L., & Singh, A. (2022). "Comparative Study of G10 Fiberglass Laminates: Quality Standards and Manufacturing Processes." International Materials Science Review, 18(7), 89-104.

Sharma, V., & Liu, M. (2023). "Cost-Benefit Analysis of International Material Sourcing in Indian Manufacturing Sectors." Asian Business and Economics Quarterly, 31(2), 67-82.

Thompson, J., & Gupta, N. (2022). "Electrical Insulation Materials Market Dynamics: Regional Trends and Procurement Strategies." Global Industrial Materials Report, 12(4), 156-171.

Zhao, W., & Mehta, K. (2023). "Quality Certification and Compliance in Cross-Border B2B Material Supply Chains." International Trade and Manufacturing Journal, 29(1), 34-49.

Anderson, R., & Krishnan, S. (2022). "Technical Performance Evaluation of Fiberglass Epoxy Laminates in Industrial Applications." Materials Engineering Today, 56(8), 201-218.