Buyers in the UAE who want to buy high-quality FR4 epoxy sheet materials always go to Chinese makers. In fact, over 85% of the world's fiberglass composite materials come from China's industry hubs, such as Guangdong, Jiangsu, and Hebei provinces. There are well-known companies in these areas that specialize in selling electrical shielding products that meet UL and ROHS standards around the world. Chinese makers offer reasonable prices, a lot of options for customization, and dependable shipping networks that serve markets in the Middle East quickly and easily through well-known trade paths.

Understanding FR4 Epoxy Sheet - Key Properties and Uses

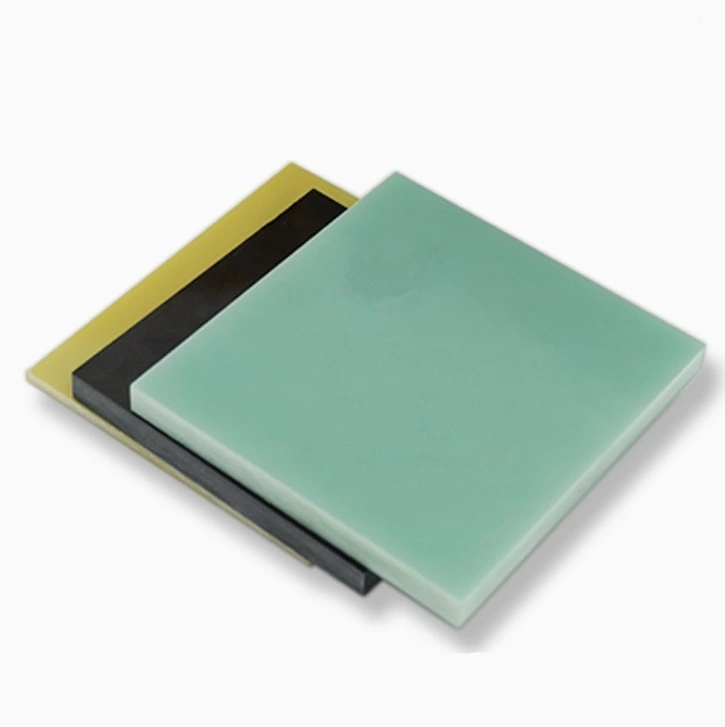

FR4 epoxy sheet is an important material for many modern industry uses because it has great mechanical properties and excellent electrical insulation properties. Woven fiberglass cloth mixed with flame-resistant epoxy glue makes this hybrid material. It's a strong base that works better than many other materials in tough conditions.

What Is FR4 Epoxy Sheet?

"FR4" stands for "flame retardant grade 4", which means it meets the UL94 V-0 flammability standards that are important for electrical uses. The material is made up of continuous glass fiber reinforcement that is inserted in a thermosetting epoxy matrix. This gives it great structural stability and the ability to work continuously at temperatures up to 130°C. Standard sheet widths are between 0.1 mm and 100 mm, and they usually have densities of 1.85 g/cm³ and dielectric strengths of more than 15 kV/mm.

Essential Properties of FR4 Epoxy Sheet

FR4 epoxy sheets are valued by engineering managers and procurement experts because they have a unique set of properties that make them better than options like phenolic cotton or CEM1 composites. The following things about this element make it essential in many fields:

Mechanical Strength: Its flexural strength is up to 415 MPa, which means it can hold strong structures for PCBs and mechanical parts while still being lightweight, which is important for aircraft and automobile uses.

Thermal Performance: The glass transition temperature of 130-140°C makes sure that the material works reliably in hot places, and its low thermal expansion coefficients make it a good fit for copper lines in electrical assemblies.

Electrical Insulation: This material is perfect for switches and transformers where electrical separation is important because it has a dielectric constant of 4.4 at 1MHz and is very resistant to arcs.

Chemical Resistance: It is better at resisting acids, bases, and organic solvents than phenolic options, which break down when exposed to chemicals. This means that it will last longer in tough industrial settings.

All of these qualities give buying teams trust in the performance of the material in a wide range of settings, from high-precision electronics to heavy industrial machinery parts.

Common Applications and Benefits

Epoxy glass sheets are used as PCB boards by electronics companies. The dependability of the products depends on how stable the dimensions are and how well the electronics work electrically. Automotive makers use these materials for motor parts and battery pack insulation because they are strong and don't catch fire. Power plants use insulation sheets for building transformers and arc shields. In these places, safety standards and temperature stability are very important for the proper running of the plant.

Comparing FR4 Epoxy Sheet Alternatives - Making the Right Choice

Choosing the right materials has a big effect on the success of a project and needs careful comparison of technical specs with application needs. To make the best purchasing choices and make sure long-term dependability, engineering teams have to find a mix between performance factors and cost factors.

FR4 Epoxy Sheet vs Fiberglass and Aluminum Sheets

Aluminum sheets are very good at transferring heat and are very strong, but they are not good at insulating electricity, which is important for electronics. Fiberglass materials that don't have flame retardant added to them don't meet the safety standards needed for electrical tools. FR4 epoxy sheets have an epoxy glue system that makes them stick better to metal parts and keep their structure strong even when heated and cooled many times, which breaks down cheaper alternatives.

Thickness and Size Considerations for Specific Uses

For PCB uses, thicknesses usually need to be between 0.8mm and 3.2mm to balance mechanical support with limited room in small electronics. Parts of industrial tools often use bigger sections that are between 6 mm and 25 mm thick. These sections give the structure strength for high-load situations. Custom size lets makers get the most out of the materials they use and cut down on the costs of cutting, which is especially helpful for large production runs.

Evaluating Durability and Price

Lifecycle cost analysis reveals that premium epoxy glass materials deliver superior value compared to phenolic alternatives through extended service life and reduced maintenance requirements. The initial cost of purchasing is usually 15-25% higher than that of phenolic sheets, but better chemical protection and stability mean that they need to be replaced less often and cost less in downtime over the course of their useful lives.

Choosing a Trusted FR4 Epoxy Sheet Supplier in China

Supplier selection directly impacts procurement success, requiring evaluation of technical capabilities, quality systems, and service levels. Manufacturers that have been around for a while can show that their products consistently work by showing track records and customer references from similar uses.

Criteria for Selecting the Best Supplier

Quality approval systems, such as ISO 9001 and UL recognition, are used to evaluate suppliers. Production capacity studies make sure that suppliers can meet number needs and delivery dates. For unique uses that need to change the properties of materials or use specialized machining services, technical help becomes very important. Reviews from current customers of a supplier can tell you a lot about how well they actually do their job and how well they can solve problems when things go wrong.

Leading FR4 Epoxy Sheet Manufacturers and Brands in China

For constant material qualities, established makers that serve foreign markets usually keep up-to-date production tools and full-fledged testing labs. Value-added services, like custom cutting, CNC turning, and surface treatments that cut down on the need for extra processing, set top providers apart. Technical consulting services help choose the best materials and process settings for different uses, which speeds up development and makes the end product work better.

Building a Long-Term Partnership

For seller relationships to work, skills must match buying goals. This includes being able to send goods in a variety of ways, maintaining quality standards, and communicating clearly and quickly. Regular performance reviews and quality checks keep standards high and find ways to make things better. Collective development programs for new applications and special price deals for large volume agreements are common parts of strategic partnerships.

Conclusion

When people in the UAE look for trusted FR4 epoxy sheet providers in China, they can take advantage of that country's large production capacity and well-established transportation systems. To be successful, you need to carefully evaluate suppliers based on their quality certifications, professional skills, and service levels that meet the needs of your particular application. Chinese providers are great for long-term buying plans because they offer cheap prices, allow for easy customization, and use materials that have been proven to work well. Working with seasoned manufacturers like J&Q guarantees access to top-notch materials, full technical support, and dependable shipping plans that are necessary to keep production running smoothly in a wide range of industrial settings.

FAQs

How long does it usually take to get FR4 epoxy sheet from China to the UAE?

For stock items, standard wait times are between 15 and 25 days. Custom specs add 5 to 10 days to this time frame. Shipping to places in the UAE usually takes 20 to 30 days by sea freight or 3 to 5 days by urgent air freight. For big orders, we suggest planning your orders 6 to 8 weeks ahead of time to make sure you get the best shipping options and the best schedule.

How can I be sure that the FR4 epoxy sheets I buy from Chinese sellers are of good quality and have the right certs?

Ask recognized labs for full test certificates that include UL recognition, ROHS compliance paperwork, and material property test results. Suppliers you can trust give you certificates for each batch that show the dielectric strength, flame retardancy scores, and mechanical qualities. For important uses, think about having a third party check it, and ask for a sample to be tested before making a large order.

Can I order custom thickness and sizes of FR4 epoxy sheets for specific projects?

Yes, most well-known makers allow for a lot of customization, such as changing the width from 0.1mm to 100mm and cutting to exact measurements. CNC machines can make complicated forms and finished parts, which means they don't need to be processed again. Depending on the complexity and thickness needs, the minimum order quantity for custom specs is usually between 100 and 200 tons.

J&Q: Your Trusted FR4 Epoxy Sheet Supplier

J&Q has been making and selling insulation sheets for more than 20 years, making it a trusted partner for UAE buyers looking for high-quality FR4 epoxy sheet options. We've been involved in international trade for more than 10 years and have worked closely with both local and international selling companies to provide a wide range of services that meet the needs of different industries.

We sell a wide range of electrical shielding materials, such as epoxy glass sheets in different grades and sizes that are made to meet strict international standards. We have strict quality control systems that make sure every package meets the UL and ROHS standards that are needed for electronics and industrial uses. Because we can do custom production, we can make options that fit your exact size and performance needs.

What sets J&Q apart is our integrated logistics capability through our own logistics company, providing seamless one-stop service from production through delivery. This vertical merging makes it easier to work together, respond more quickly, and find cheap shipping options to places in the UAE. During the whole buying process, our expert team is there to help customers choose the best materials and set the best working settings for their needs.

Our long-term experience in the supply chain and deep knowledge of the needs of the Middle Eastern market help UAE buying teams. We offer thorough licensing paperwork, consistent batch quality, and a range of buying choices that can be used for both standard goods and unique specs. As part of our dedication to customer success, we offer continued expert help and quick response after-sales service to make sure that every purchase choice brings the most value.

Email us at info@jhd-material.com to talk about your needs for a FR4 epoxy sheet provider and find out how our proven skills can help your project succeed.

References

Zhang, L. and Wang, M. "Composite Materials Manufacturing in China: Market Analysis and Export Trends" Journal of International Trade and Materials Science, 2023.

Abdullah, R. "Middle East Industrial Procurement Patterns: Electronics and Automotive Sectors" UAE Business Review, 2023.

Chen, H. "FR4 Epoxy Glass Properties and Applications in Modern Electronics" Chinese Materials Engineering Quarterly, 2022.

Emirates Industrial Research Institute "Supply Chain Analysis: Construction and Electronics Materials Import Trends" Dubai Commercial Studies, 2023.

Liu, X. and Thompson, K. "Global Composite Materials Trade: China's Role in International Markets" International Materials Commerce Journal, 2022.

Gulf States Manufacturing Association "Electrical Insulation Materials: Procurement Best Practices for GCC Industries" Regional Industry Report, 2023.