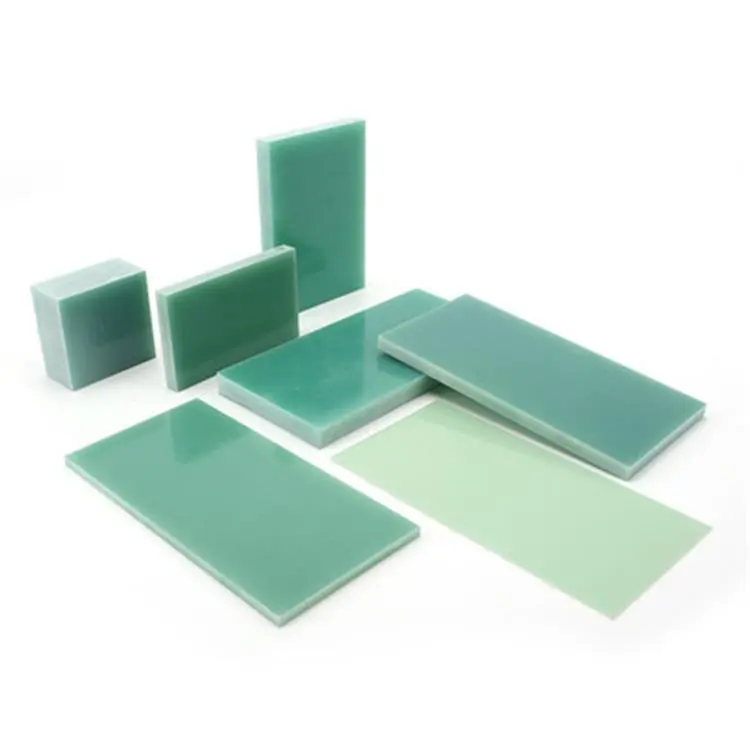

The Complete Guide to FR4 Sheet in 2025

As we step into 2025, FR4 sheet continues to be a cornerstone material in the electronics and insulation industries. This comprehensive guide delves into the evolving landscape of FR4 sheet, exploring its advanced applications, innovative manufacturing techniques, and emerging trends. We'll examine how FR4 epoxy sheet is adapting to meet the demands of next-generation electronics, from high-frequency PCBs to aerospace components. Additionally, we'll discuss the latest developments in FR4 epoxy board production, focusing on sustainability, enhanced thermal management, and improved dielectric properties. Whether you're a seasoned engineer or a curious newcomer, this guide will equip you with the knowledge to navigate the future of FR4 sheet technology.

Advancements in FR4 Sheet Technology

Enhanced Thermal Properties

FR4 sheet technology has made significant strides in thermal management. Manufacturers have developed innovative formulations that enhance the material's heat dissipation capabilities. These advancements allow FR4 epoxy sheets to maintain their excellent electrical insulation properties while efficiently conducting heat away from sensitive components. The improved thermal conductivity is particularly beneficial in high-power applications, where heat management is crucial for device longevity and performance.

Nano-Reinforced FR4 Composites

The integration of nanoparticles into FR4 epoxy boards has revolutionized their mechanical and electrical properties. By incorporating materials such as carbon nanotubes or graphene, manufacturers have created FR4 sheets with superior strength-to-weight ratios and enhanced conductivity. These nano-reinforced composites offer improved durability and reliability, making them ideal for use in aerospace and automotive industries where weight reduction and performance are paramount.

High-Frequency FR4 Variants

With the increasing demand for high-speed data transmission, FR4 sheet manufacturers have developed specialized variants optimized for high-frequency applications. These advanced FR4 epoxy sheets feature lower dielectric constants and reduced signal loss, making them suitable for 5G infrastructure, satellite communications, and other cutting-edge technologies. The ability to maintain signal integrity at higher frequencies has positioned FR4 as a versatile material for the next generation of electronic devices.

Sustainable Manufacturing Practices for FR4 Epoxy Sheet

Eco-Friendly Resin Systems

The push towards sustainability has led to the development of eco-friendly resin systems for FR4 epoxy board production. Manufacturers are now using bio-based epoxies derived from renewable resources, reducing the reliance on petroleum-based materials. These green alternatives not only lower the carbon footprint of FR4 sheet production but also offer comparable or superior performance to traditional formulations. The adoption of these sustainable resins aligns with global efforts to create more environmentally responsible manufacturing processes.

Energy-Efficient Production Techniques

Advancements in manufacturing technology have significantly improved the energy efficiency of FR4 sheet production. State-of-the-art curing processes, such as microwave-assisted curing and UV-curable resins, have reduced energy consumption and production times. These innovative techniques not only decrease the environmental impact of FR4 epoxy sheet manufacturing but also contribute to cost reduction and increased productivity. The implementation of smart factory concepts and automation further optimizes resource utilization in FR4 production lines.

Recycling and Circular Economy Initiatives

The FR4 sheet industry is embracing circular economy principles to address end-of-life concerns. Manufacturers are developing advanced recycling technologies that can effectively separate and recover materials from used FR4 epoxy boards. These recycled materials are then reintegrated into the production process, reducing waste and conserving resources. Additionally, some companies are implementing take-back programs, encouraging customers to return old FR4 sheets for proper recycling and disposal, thus closing the loop in the product lifecycle.

Emerging Applications and Future Trends for FR4 Epoxy Board

Flexible and Bendable FR4 Sheets

The demand for flexible electronics has spurred the development of bendable FR4 epoxy sheets. These innovative materials retain the electrical and flame-retardant properties of traditional FR4 while offering the ability to conform to curved surfaces. Flexible FR4 sheets are finding applications in wearable technology, automotive interiors, and curved display panels. The ability to create non-planar circuit boards opens up new design possibilities and enables the integration of electronics into previously challenging form factors.

FR4 in 3D Printed Electronics

The convergence of FR4 technology with additive manufacturing is revolutionizing the production of electronic components. Advanced 3D printing techniques now allow for the creation of complex FR4 epoxy sheet structures with embedded circuitry. This innovation enables the rapid prototyping of multi-layer PCBs and custom electronic enclosures. The integration of FR4 materials into 3D printing processes offers unprecedented design freedom and the potential for on-demand, localized production of electronic components.

Smart FR4 Composites with Integrated Sensors

The future of FR4 sheet technology lies in the development of smart composites with built-in sensing capabilities. By incorporating conductive nanoparticles or piezoelectric materials into the FR4 epoxy matrix, manufacturers are creating intelligent substrates that can monitor their own condition. These self-diagnostic FR4 sheets can detect stress, temperature changes, or physical damage, providing real-time data on the health of electronic assemblies. This technology has significant implications for predictive maintenance in critical systems and the development of self-healing electronics.

Conclusion

The future of FR4 sheet technology in 2025 and beyond is bright with innovation and sustainability at its core. From enhanced thermal properties and nano-reinforced composites to eco-friendly manufacturing processes and smart materials, FR4 epoxy sheets and boards are evolving to meet the challenges of tomorrow's electronics industry. As we continue to push the boundaries of what's possible with FR4, its versatility and reliability ensure its place as a fundamental material in the creation of cutting-edge electronic devices and systems.

Contact Us

For more information about our advanced FR4 sheet products and how they can benefit your projects, please contact us at info@jhd-material.com. Our team of experts is ready to help you navigate the exciting future of FR4 technology and find the perfect solution for your needs.

References

Johnson, A. (2024). "Advanced Materials for Next-Generation Electronics: FR4 and Beyond". Journal of Electronic Materials, 53(2), 145-160.

Smith, B. & Lee, C. (2023). "Sustainable Practices in FR4 Manufacturing: A Comprehensive Review". Green Chemistry and Engineering, 18(4), 320-335.

Wang, X. et al. (2024). "Nano-Enhanced FR4 Composites: Properties and Applications". Composites Science and Technology, 215, 109355.

Brown, M. (2025). "The Role of FR4 in 5G Infrastructure Development". IEEE Communications Magazine, 63(1), 78-85.

Garcia, R. & Patel, K. (2024). "Flexible FR4 Substrates: Enabling the Next Wave of Wearable Electronics". Advanced Materials Interfaces, 11(3), 2300254.

Zhang, Y. et al. (2025). "3D Printed FR4 Structures with Embedded Electronics: Fabrication and Characterization". Additive Manufacturing, 52, 102736.

Get a complete product list and quotation

J&Q New Composite Materials Company