How Do FR4 and G10 Compare in Strength and Durability?

Mechanical Properties of FR4 and G10

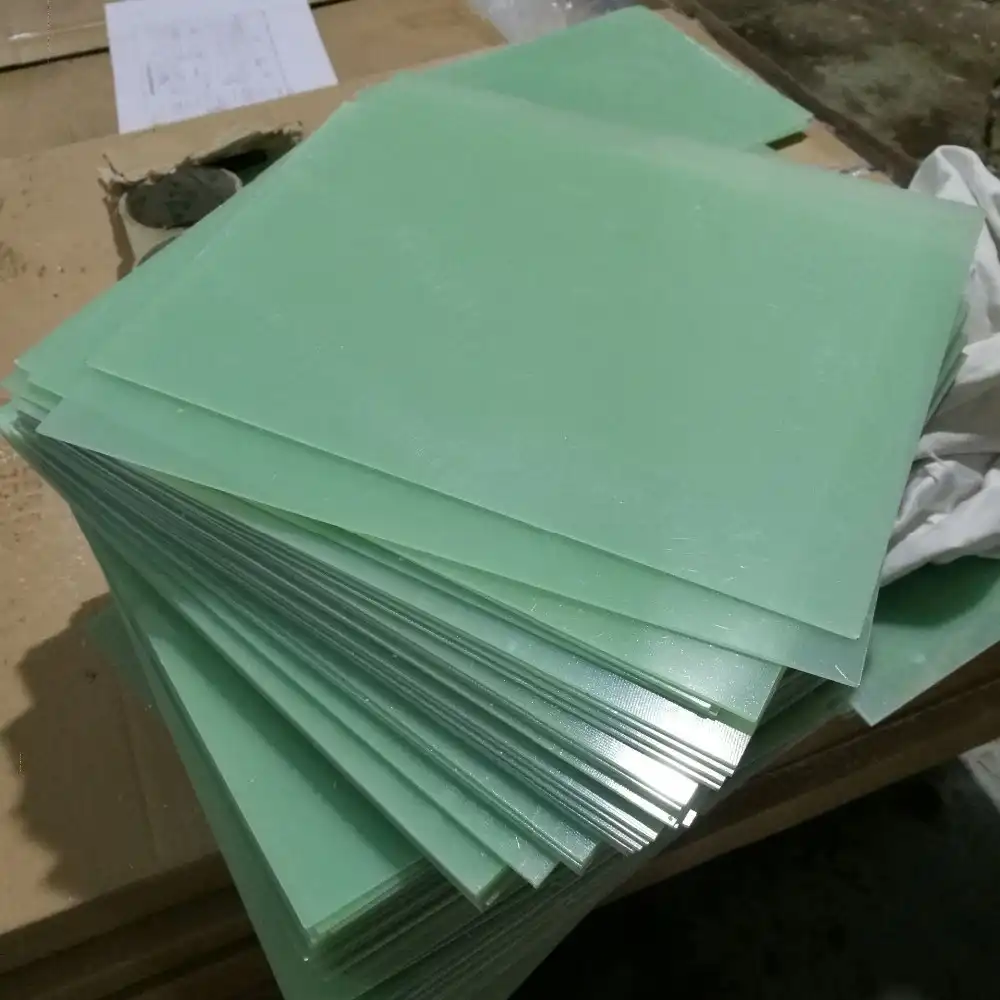

FR4 and G10 sheets exhibit remarkable mechanical strength, owing to their fiberglass reinforcement. Both materials boast high tensile and flexural strength, making them ideal for applications requiring structural integrity. The glass fibers woven into the epoxy resin matrix provide excellent dimensional stability, ensuring that boards maintain their shape under various environmental conditions.

Impact Resistance and Toughness

When it comes to impact resistance, FR4 and G10 demonstrate comparable performance. Their composite structure allows them to absorb and dissipate energy from sudden impacts effectively. This toughness is particularly valuable in electronic devices that may be subjected to shocks or vibrations during operation or transportation.

Long-term Durability and Aging Characteristics

Both FR4 and G10 sheets exhibit excellent long-term durability. They resist degradation from exposure to various environmental factors, including humidity, temperature fluctuations, and certain chemicals. However, FR4's flame-retardant properties may give it a slight edge in applications where fire safety is a critical concern, potentially extending the lifespan of devices in which it is used.

Electrical Insulation Properties of FR4 vs G10

Dielectric Strength Comparison

FR4 and G10 sheets are renowned for their exceptional dielectric strength, which measures their ability to withstand electric fields without breaking down. Both materials can withstand high voltages before experiencing dielectric breakdown. This property is crucial in PCB applications, where maintaining electrical isolation between components is paramount.

Insulation Resistance and Breakdown Voltage

The insulation resistance of FR4 and G10 is remarkably high, ensuring minimal current leakage across the board. This characteristic is essential for maintaining signal integrity in electronic circuits. The breakdown voltage, or the point at which the material ceases to act as an insulator, is also substantial for both FR4 and G10, providing a wide safety margin in high-voltage applications.

Performance in High-Frequency Applications

In high-frequency applications, both FR4 and G10 sheets perform admirably. They exhibit low dielectric loss, which is crucial for maintaining signal quality in high-speed digital circuits. However, for extremely high-frequency applications, specialized materials may be preferred over standard FR4 or G10.

Cost and Availability of FR4 and G10 in the PCB Market

Market Pricing Trends for FR4 and G10 Sheets

FR4 sheets are generally more widely available and tend to be more cost-effective than G10 sheets. This is largely due to FR4’s flame-retardant properties, which have established it as the industry standard for the majority of PCB applications. The higher production volumes of FR4 contribute to competitive pricing and easier accessibility. In contrast, G10, while still accessible, often carries a slightly higher price point because of lower demand and smaller production scale, affecting its market pricing dynamics.

Supply Chain Considerations for Manufacturers

FR4’s widespread adoption in the electronics sector means it benefits from a well-established and resilient supply chain. Manufacturers can source FR4 sheets from a variety of suppliers, which helps reduce lead times and minimize supply risks. On the other hand, G10, although still available, typically has a more limited supplier base. This narrower supply network can pose challenges for procurement, requiring manufacturers who prefer G10 to carefully manage sourcing strategies to avoid potential delays or shortages.

Long-term Cost-Effectiveness Analysis

When evaluating long-term cost-effectiveness, the flame-retardant qualities of FR4 may add significant value in applications where fire safety is paramount. This can lead to reduced fire-related risks and potential cost savings over the lifecycle of a product. However, in scenarios where flame retardancy is less critical, G10 may provide comparable performance, sometimes at a lower cost depending on market conditions and supplier agreements. Ultimately, material choice should balance performance requirements with economic considerations for optimal value.

Conclusion

FR4 sheets and G10 sheets are both exceptional materials for PCB manufacturing, each with its own strengths. FR4's flame-retardant properties make it the go-to choice for most modern electronic applications, while G10 remains a viable option where fire resistance is not a primary concern. Both materials offer excellent mechanical strength, durability, and electrical insulation properties. The choice between FR4 and G10 ultimately depends on specific application requirements, regulatory considerations, and cost factors. As technology evolves, these materials continue to play a crucial role in the electronics industry, supporting the development of reliable and efficient electronic devices.

Contact Us

For more information about FR4 and G10 sheets and how they can benefit your specific applications, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you in selecting the right material for your needs and provide comprehensive support throughout your project.