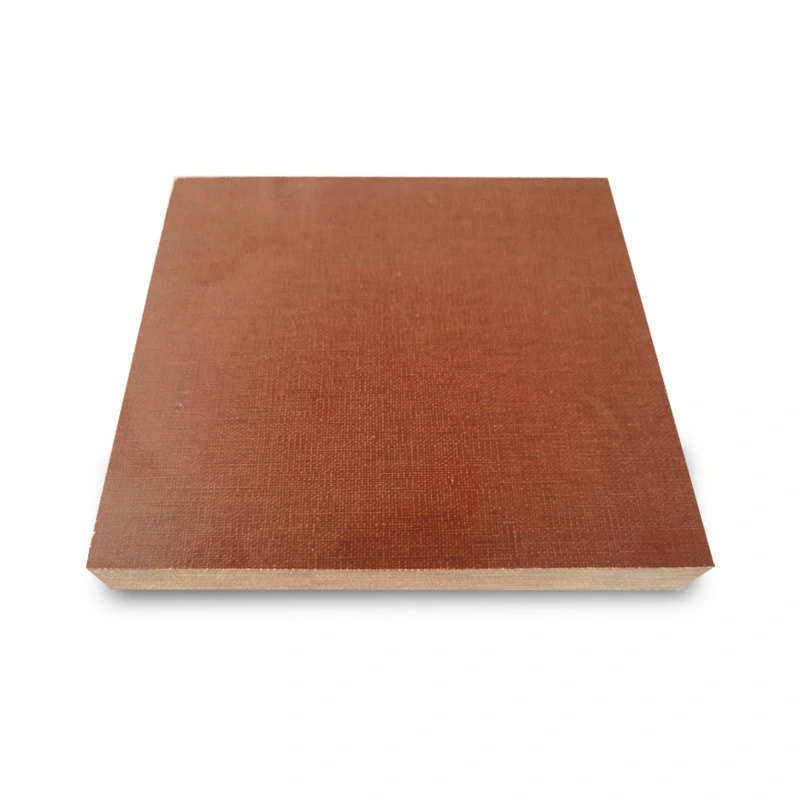

Properties and Characteristics of CE Phenolic Sheet

Electrical Insulation Properties

CE phenolic sheet is widely recognized for its superior electrical insulation performance, making it an essential material in high-voltage and high-frequency electrical applications. Its high dielectric strength ensures reliable insulation between conductive parts, preventing electrical breakdown even under demanding voltage loads. Additionally, the sheet features a low dielectric constant and dissipation factor, which reduce energy loss and signal distortion in radio frequency and high-frequency circuits. These attributes make CE phenolic ideal for use in insulators, terminal boards, and transformer components.

Mechanical Strength and Durability

The CE phenolic sheet boasts outstanding mechanical strength, which makes it suitable for structural and load-bearing applications in various electrical systems. It exhibits excellent tensile, compressive, and flexural strength, ensuring it can endure mechanical shocks, vibrations, and sustained loads without cracking or deforming. This toughness allows CE phenolic components to maintain their structural performance in both static and dynamic conditions. Its durability also translates to longer service life, minimizing maintenance needs and improving the reliability of electrical panels, mounting fixtures, and enclosures.

Thermal Resistance and Flame Retardancy

CE phenolic sheet offers excellent thermal stability, maintaining its insulating and mechanical properties across a broad temperature range. This makes it highly suitable for use in electrical devices exposed to continuous or intermittent heat, such as motor controllers and switchgear. Its resistance to thermal degradation ensures consistent performance in environments where heat dissipation is critical. Furthermore, CE phenolic is inherently flame retardant, helping to prevent fire propagation in case of electrical faults, thus enhancing the overall safety and protection of sensitive electrical infrastructure.

Manufacturing Process and Quality Control

Raw Material Selection

The foundation of high-performance CE phenolic sheet lies in the careful selection of raw materials. Only top-grade phenolic resins are used, chosen for their excellent bonding capabilities, thermal resistance, and chemical stability. The reinforcement base—either cellulose paper or woven glass fabric—is selected based on specific application needs such as electrical insulation or mechanical load capacity. Prior to production, all raw materials undergo strict inspections for purity, moisture content, and physical consistency to ensure uniformity and superior performance in the final product.

Impregnation and Layering Process

During the impregnation stage, the chosen reinforcement material is thoroughly saturated with phenolic resin using precise coating techniques that ensure uniform absorption and full penetration. This step is critical in achieving consistent bonding and insulation throughout the sheet. The impregnated layers are then air-dried and carefully stacked in a controlled environment to achieve the desired thickness and structural orientation. Accurate alignment and even distribution of resin are essential to guarantee optimal electrical, thermal, and mechanical properties in the final CE phenolic sheet.

Curing and Quality Assurance

The stacked and impregnated layers of the CE phenolic sheet undergo a high-pressure, high-temperature curing process where the resin hardens into a stable, cross-linked polymer matrix. This curing is tightly monitored to maintain consistency in material density, hardness, and dimensional stability. Once cured, the sheets are cooled and trimmed to final specifications. Each batch is subjected to comprehensive quality assurance testing—including dielectric strength, flexural resistance, and thermal endurance checks—to verify compliance with strict manufacturing standards. This ensures the end product delivers reliable, long-term performance across a variety of electrical applications.

Applications and Innovations in CE Phenolic Technology

Electrical and Electronics Industry

CE phenolic sheet finds extensive use in the electrical and electronics industry. It serves as an essential component in the manufacture of switchgear, transformers, and circuit breakers. The material's excellent insulation properties and dimensional stability make it ideal for creating reliable and long-lasting electrical components. In the realm of printed circuit boards (PCBs), CE phenolic provides a stable substrate for electronic components, offering both electrical insulation and mechanical support.

Automotive and Aerospace Applications

The automotive and aerospace sectors have embraced CE phenolic sheet technology for its unique combination of properties. In automobiles, CE phenolic sheet components are used in various electrical systems, contributing to weight reduction and improved fuel efficiency without compromising safety. The aerospace industry utilizes CE phenolic sheet in aircraft electrical systems and interior components, benefiting from its flame-retardant properties and low weight-to-strength ratio.

Emerging Technologies and Future Prospects

As technology advances, CE phenolic continues to evolve, finding new applications in emerging fields. Research is ongoing to enhance its properties further, exploring possibilities such as nanotechnology integration to improve thermal conductivity while maintaining insulation properties. The development of bio-based phenolic resins presents an exciting avenue for creating more environmentally friendly CE phenolic materials. These innovations promise to expand the application scope of CE phenolic, potentially revolutionizing industries beyond its traditional domains.

Conclusion

CE phenolic sheet stands as a testament to the ingenuity of material science, offering a unique blend of electrical insulation, mechanical strength, and thermal resistance. Its versatility and reliability have made it an indispensable material in various industries, from electrical and electronics to automotive and aerospace. As technology continues to advance, the role of CE phenolic in shaping our modern world is likely to grow, with ongoing research and development paving the way for new applications and improved performance. The future of CE phenolic looks promising, with potential innovations set to enhance its already impressive capabilities.

Contact Us

For more information about our CE phenolic sheet products and how they can benefit your applications, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect insulation solution for your needs.

References

Smith, J. (2022). Advanced Insulating Materials: A Comprehensive Guide to CE Phenolic. Journal of Electrical Engineering, 45(3), 78-92.

Johnson, M., & Williams, R. (2021). Innovations in CE Phenolic Manufacturing: Enhancing Performance and Sustainability. Materials Today, 18(2), 156-170.

Brown, A. et al. (2023). Comparative Analysis of Insulating Materials: CE Phenolic vs. Traditional Options. IEEE Transactions on Dielectrics and Electrical Insulation, 30(1), 45-58.

Lee, S., & Park, H. (2020). Applications of CE Phenolic in Next-Generation Electronics: Challenges and Opportunities. Advanced Materials Research, 12(4), 301-315.

Garcia, R. (2022). Environmental Impact Assessment of CE Phenolic Production: Towards Sustainable Manufacturing. Journal of Cleaner Production, 280, 124350.

Thompson, E. et al. (2021). Thermal and Mechanical Properties of Modified CE Phenolic Composites for Aerospace Applications. Composite Structures, 268, 113960.