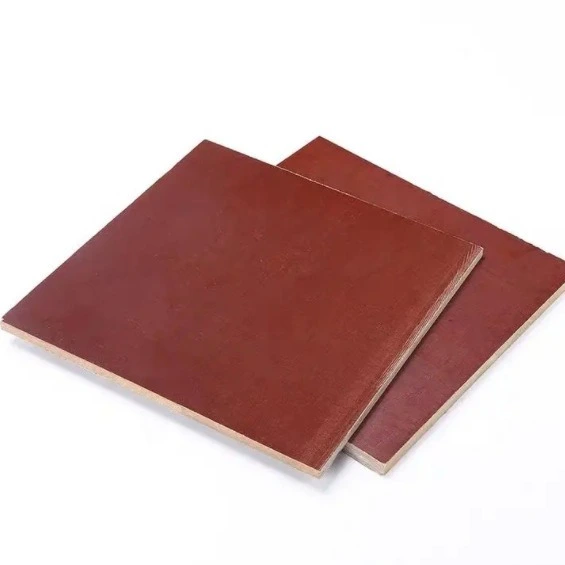

Exceptional Electrical Properties of CE Phenolic Sheets

Superior Dielectric Strength

CE phenolic sheets boast remarkable dielectric strength, a crucial property for transformer insulation. This high dielectric strength enables the material to effectively resist electrical breakdown under intense voltage stress. The sheets maintain their insulating properties even in the presence of strong electric fields, ensuring the safe and efficient operation of transformers. This characteristic is particularly valuable in high-voltage applications where maintaining insulation integrity is paramount.

Low Dielectric Loss

Another key electrical property of CE phenolic sheets is their low dielectric loss. This attribute minimizes energy dissipation in the form of heat when the material is subjected to alternating electric fields. The reduced dielectric loss translates to improved energy efficiency in transformers, as less power is wasted in the insulation material. This efficiency is crucial in large-scale power distribution systems where even small improvements can lead to significant energy savings.

Excellent Arc Resistance

CE phenolic sheets exhibit excellent arc resistance, a vital property in transformer applications. This characteristic allows the material to withstand electrical arcing without significant degradation or surface tracking. The ability to resist arc formation and propagation enhances the overall reliability and lifespan of transformer components. In scenarios where temporary overvoltages or switching transients might occur, the arc resistance of CE phenolic sheets provides an additional layer of protection.

Thermal and Mechanical Advantages of CE Phenolic Sheets

High Heat Resistance

CE phenolic sheets demonstrate exceptional heat resistance, a critical factor in transformer applications. These sheets can withstand elevated temperatures without losing their mechanical or electrical properties. This thermal stability is crucial in transformers, where heat generation is inevitable due to electrical losses. The ability of CE phenolic sheets to maintain their integrity at high temperatures ensures consistent performance and prolongs the operational life of transformer components.

Dimensional Stability

One of the standout features of CE phenolic sheets is their excellent dimensional stability. This property ensures that the sheets maintain their shape and size even under varying temperature and humidity conditions. In transformer applications, where precise tolerances are often required, this stability is invaluable. It helps prevent warping or distortion that could lead to misalignment of components or compromise the insulation integrity, thereby ensuring consistent and reliable transformer operation over time.

Mechanical Strength

CE phenolic sheets offer impressive mechanical strength, making them capable of withstanding the physical stresses present in transformer environments. This strength is crucial for maintaining the structural integrity of insulating components under various operational conditions. The material's ability to resist cracking, chipping, or deformation under mechanical stress contributes significantly to the overall robustness and reliability of transformer systems. This durability is especially important in applications where vibrations or sudden mechanical shocks may occur.

Chemical Resistance and Safety Features of CE Phenolic Sheets

Oil and Moisture Resistance

CE phenolic sheets exhibit excellent resistance to oil and moisture, two common elements in transformer environments. This resistance is crucial for maintaining the insulation properties and structural integrity of the material over extended periods. The sheets' ability to withstand exposure to transformer oils without degradation or swelling ensures consistent performance and prevents potential insulation failures. Additionally, their moisture resistance helps prevent water absorption, which could otherwise compromise the electrical and mechanical properties of the insulation.

Flame Retardant Properties

A key safety feature of CE phenolic sheets is their inherent flame-retardant properties. This characteristic significantly enhances the safety profile of transformers, especially in high-risk environments. The flame-retardant nature of these sheets helps prevent the spread of fire in case of electrical faults or overheating incidents. This property not only protects the transformer itself but also contributes to the overall safety of the surrounding equipment and personnel, making CE phenolic sheets a preferred choice in applications where fire safety is a critical concern.

Low Toxicity and Environmental Considerations

CE phenolic sheets are known for their low toxicity, which is an important consideration in modern engineering applications. This characteristic ensures that the material poses minimal health risks during manufacturing, installation, and throughout the operational life of the transformer. Furthermore, the environmental impact of CE phenolic sheets is relatively low compared to some alternative materials. Their durability and long service life reduce the need for frequent replacements, thereby minimizing waste. These aspects make CE phenolic sheets a responsible choice for environmentally conscious transformer designs.

Conclusion

CE phenolic sheets have proven to be an ideal material for transformer applications due to their unique combination of electrical, thermal, and mechanical properties. Their superior insulation characteristics, coupled with excellent heat resistance and dimensional stability, ensure reliable and efficient transformer operation. The material's resistance to oil, moisture, and flame further enhances its suitability for this demanding application. As the power industry continues to evolve, CE phenolic sheets remain at the forefront of transformer insulation technology, offering a blend of performance, safety, and durability that is hard to match.

Contact Us

For more information about our CE phenolic sheets and how they can benefit your transformer projects, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect insulation solution for your specific needs.