Understanding FR4 Epoxy Sheets: Composition and Properties

Chemical Makeup of FR4 Epoxy Sheets

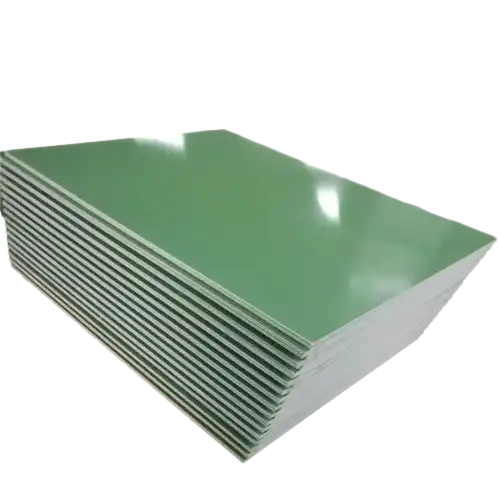

FR4 epoxy sheets are composite materials consisting of woven fiberglass cloth impregnated with epoxy resin. The fiberglass provides structural strength, while the epoxy resin acts as a binder and offers excellent electrical insulation properties. This composition results in a material that is both sturdy and versatile, making FR4 epoxy boards ideal for numerous applications in electronics and manufacturing.

Key Properties of FR4 Epoxy Boards

FR4 epoxy sheets boast an impressive array of properties that contribute to their widespread use. They exhibit exceptional electrical insulation, with a high dielectric strength and low dielectric constant. These boards also demonstrate remarkable mechanical strength, resilience to moisture absorption, and flame-retardant characteristics. The thermal stability of FR4 epoxy boards allows them to maintain their properties across a wide temperature range, enhancing their reliability in diverse operating conditions.

Common Applications of FR4 Epoxy Sheets

The versatility of FR4 epoxy sheets makes them indispensable in various industries. They serve as the foundation for printed circuit boards (PCBs) in electronic devices, from smartphones to industrial control systems. Beyond electronics, FR4 epoxy boards find applications in aerospace, automotive, and renewable energy sectors. Their combination of electrical insulation and mechanical strength makes them suitable for creating insulating components, structural elements, and even decorative panels in specialized applications.

Optimal Storage Conditions for FR4 Epoxy Sheets

Temperature and Humidity Control

Maintaining appropriate temperature and humidity levels is paramount for preserving the integrity of FR4 epoxy sheets. The ideal storage environment should have a temperature range of 20-25°C (68-77°F) and relative humidity between 40-60%. Fluctuations beyond these parameters can lead to dimensional changes, warping, or degradation of the epoxy resin. Consider using climate-controlled storage areas or specialized cabinets equipped with dehumidifiers to maintain consistent conditions. Regular monitoring of temperature and humidity levels using calibrated instruments can help ensure optimal storage conditions are maintained consistently.

Protection from Light and UV Exposure

FR4 epoxy sheets are susceptible to degradation when exposed to prolonged periods of direct sunlight or intense artificial light. Ultraviolet (UV) radiation can cause discoloration, brittleness, and deterioration of the epoxy resin matrix. To mitigate these risks, store FR4 epoxy boards in opaque containers or wrap them in UV-resistant materials. If storage in a naturally lit area is unavoidable, consider installing UV-filtering films on windows or using specialized storage cabinets with built-in light protection. By shielding FR4 epoxy sheets from harmful light exposure, you can significantly extend their shelf life and maintain their original properties.

Proper Stacking and Support Techniques

The way FR4 epoxy sheets are stacked and supported during storage plays a crucial role in preventing deformation and damage. Always stack sheets horizontally on a flat, level surface to distribute weight evenly and prevent warping. Use clean, non-abrasive separators between each sheet to prevent scratching and allow air circulation. For larger sheets, consider using specially designed racks or shelving systems that provide full support across the entire surface area. When handling stacked FR4 epoxy boards, exercise caution to avoid applying uneven pressure or causing flexing, which could lead to internal stress or delamination. Implementing these stacking and support techniques will help maintain the flatness and structural integrity of FR4 epoxy sheets throughout their storage period.

Best Practices for Handling FR4 Epoxy Sheets

Proper Lifting and Transportation Techniques

When handling FR4 epoxy sheets, employ proper lifting techniques to prevent damage and ensure personal safety. For smaller sheets, use both hands to support the material evenly. Larger sheets may require two or more people to lift and move safely. Utilize material handling equipment such as vacuum lifters or panel carts for heavier or larger quantities of FR4 epoxy boards. During transportation, secure the sheets to prevent shifting or sliding, which could cause edge damage or warping. Consider using edge protectors and cushioning materials to safeguard the sheets during transit. By adopting these conscientious handling practices, you can minimize the risk of accidental damage and maintain the quality of your FR4 epoxy sheets.

Cleanliness and Contamination Prevention

Maintaining a clean handling environment is crucial for preserving the quality of FR4 epoxy sheets. Always wear clean, lint-free gloves when handling the material to prevent oil and dirt transfer from skin contact. Ensure work surfaces are clean and free from debris before placing FR4 epoxy boards on them. Implement a regular cleaning schedule for storage areas and handling equipment to minimize the risk of contamination. If sheets become soiled, clean them gently using isopropyl alcohol or a specialized cleaner recommended for FR4 materials. Avoiding contamination is particularly important for FR4 epoxy sheets destined for use in sensitive electronic applications, where even minor impurities can impact performance.

Acclimatization Before Use

Before utilizing FR4 epoxy sheets in manufacturing processes, it's essential to allow them to acclimatize to the environment in which they will be used. This process helps prevent issues related to thermal expansion or contraction that could affect dimensional stability or cause warping. Remove the sheets from their storage packaging and allow them to equilibrate to room temperature and humidity for at least 24 hours prior to use. For critical applications, consider extending the acclimatization period to 48-72 hours to ensure complete stabilization. By incorporating this acclimatization step into your workflow, you can enhance the consistency and quality of your final products, especially in applications requiring precise dimensional tolerances.

Conclusion

Proper storage and handling of FR4 epoxy sheets are indispensable for maintaining their exceptional properties and ensuring optimal performance in various applications. By implementing the strategies outlined in this guide, including controlling environmental conditions, protecting from light exposure, using appropriate stacking techniques, and following best handling practices, you can significantly extend the lifespan and reliability of your FR4 epoxy boards. Remember that consistent care and attention to detail in storage and handling processes will ultimately translate to higher quality end products and more efficient manufacturing operations.

Contact Us

For more information about our high-quality FR4 epoxy sheets and expert guidance on their use and storage, please don't hesitate to contact us at info@jhd-material.com. Our team of specialists is ready to assist you in optimizing your FR4 epoxy board applications and ensuring long-term performance without loss.