The Composition and Properties of FR4 Glass Epoxy

Chemical Composition of FR4

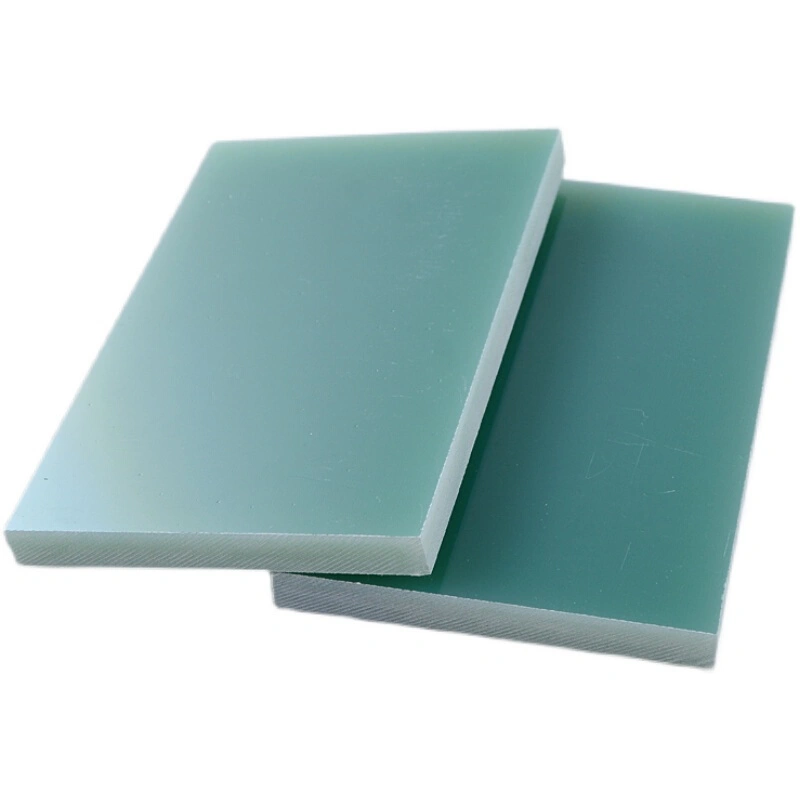

FR4 glass epoxy sheet is a high-performance composite material combining woven fiberglass cloth with a specially formulated epoxy resin system. The fiberglass layers provide essential structural reinforcement, enhancing strength and dimensional stability under mechanical and thermal stresses. The epoxy resin acts as a strong adhesive and excellent electrical insulator, ensuring durability and performance in demanding environments. Additionally, FR4 incorporates flame-retardant additives, indicated by “FR,” which help prevent combustion, making it a safer choice for electronic circuit boards and other critical applications.

Mechanical Properties

The mechanical robustness of FR4 glass epoxy sheet makes it highly suitable for use as a substrate in electronic devices. It demonstrates superior flexural strength, tensile strength, and impact resistance, enabling it to endure the rigors of fabrication processes and everyday handling. Its low coefficient of thermal expansion helps maintain consistent dimensions despite temperature fluctuations, which is vital for preserving the alignment and connectivity of circuit elements. These mechanical qualities contribute significantly to the reliability and longevity of FR4-based electronic components.

Electrical Characteristics

FR4 excels in electrical performance, offering high dielectric strength that prevents electrical breakdown and short circuits. Its low dielectric constant reduces capacitive coupling and signal loss, which is crucial for maintaining signal integrity in high-frequency circuits. The material also possesses excellent insulation resistance, effectively isolating conductive pathways and minimizing electromagnetic interference. These electrical properties make FR4 an ideal substrate for complex multilayer printed circuit boards, ensuring dependable operation in various consumer, industrial, and telecommunications applications.

Applications of FR4 Glass Epoxy in Electronic Devices

Printed Circuit Boards (PCBs)

FR4 glass epoxy sheet is predominantly used in the fabrication of printed circuit boards (PCBs), which are essential for assembling electronic circuits. The material provides a robust and stable base for soldering electronic components while ensuring electrical insulation between conductive layers. Its mechanical strength and dimensional stability enable the production of multi-layer PCBs that support complex circuit designs found in computers, telecommunications equipment, and industrial electronics. FR4’s fire resistance and thermal properties further enhance the safety and durability of PCBs in various operating environments.

Consumer Electronics

In consumer electronics, FR4 glass epoxy sheet serves as the backbone for countless devices, ranging from smartphones and tablets to wearable technology and smart home products. The high reliability and consistent performance of FR4-based PCBs ensure that these devices operate efficiently over long periods, even under frequent use. Its excellent insulation and heat resistance protect sensitive electronic components from damage due to electrical surges or thermal stress, contributing significantly to the durability and user satisfaction of everyday electronic gadgets.

Industrial and Aerospace Applications

FR4 glass epoxy is highly valued in industrial and aerospace sectors due to its resilience and stability under challenging conditions. It is used extensively in automotive electronics, industrial automation systems, and aerospace control units where exposure to extreme temperatures, vibration, and mechanical stress is common. The material’s flame retardant properties and robust electrical insulation enhance the safety and reliability of critical systems in aircraft, satellites, and heavy machinery. These attributes make FR4 indispensable for ensuring operational integrity in mission-critical environments.

Advantages of FR4 Glass Epoxy in Electronic Manufacturing

Cost-Effectiveness and Availability

FR4 glass epoxy sheet provides an excellent balance between cost and performance, making it the preferred choice in electronic manufacturing. Due to its widespread use, production techniques have become highly efficient, lowering manufacturing costs and ensuring consistent quality. This high availability means that manufacturers can source FR4 sheets easily and reliably, which helps keep overall production expenses down. As a result, businesses can offer affordable yet high-performance electronic devices, benefiting end-users with both quality and cost savings.

Manufacturability and Processing

The manufacturability of FR4 glass epoxy sheet is a major advantage in PCB production. The material’s properties allow for precise drilling, routing, and plating, enabling complex multilayer circuit board designs with dense component layouts. FR4 sheets are compatible with a wide range of surface finishes, such as HASL, ENIG, and OSP, which support various soldering techniques. This adaptability simplifies manufacturing workflows, reduces errors, and enhances yield, making FR4 an efficient and reliable substrate for diverse electronic applications.

Environmental Considerations

Growing environmental awareness has led to innovations in FR4 glass epoxy production. Halogen-free FR4 variants are now available, which reduce toxic emissions during manufacturing and end-of-life disposal, aligning with global environmental regulations. Additionally, the durability and longevity of FR4-based products contribute to extended device lifespans, lowering the frequency of electronic replacements and thus reducing electronic waste. These sustainable improvements help manufacturers address environmental concerns without compromising the material’s excellent electrical and mechanical performance.

Conclusion

FR4 glass epoxy sheet has legitimately earned its put as the spine of high-quality electronic gadgets. Its special combination of mechanical quality, electrical properties, and manufacturability makes it an crucial fabric in the hardware industry. As innovation proceeds to development, FR4 glass epoxy advances to meet unused challenges, guaranteeing its significance in future eras of electronic gadgets. The material's flexibility, unwavering quality, and cost-effectiveness set its position as a foundation of advancement in hardware, empowering the creation of progressively advanced and compact gadgets that control our advanced world.

Contact Us

For more information about our FR4 glass epoxy sheets and how they can enhance your electronic manufacturing processes, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your specific needs.