Electrical Insulation and Dielectric Strength Benefits of FR4

Superior Electrical Insulation Properties

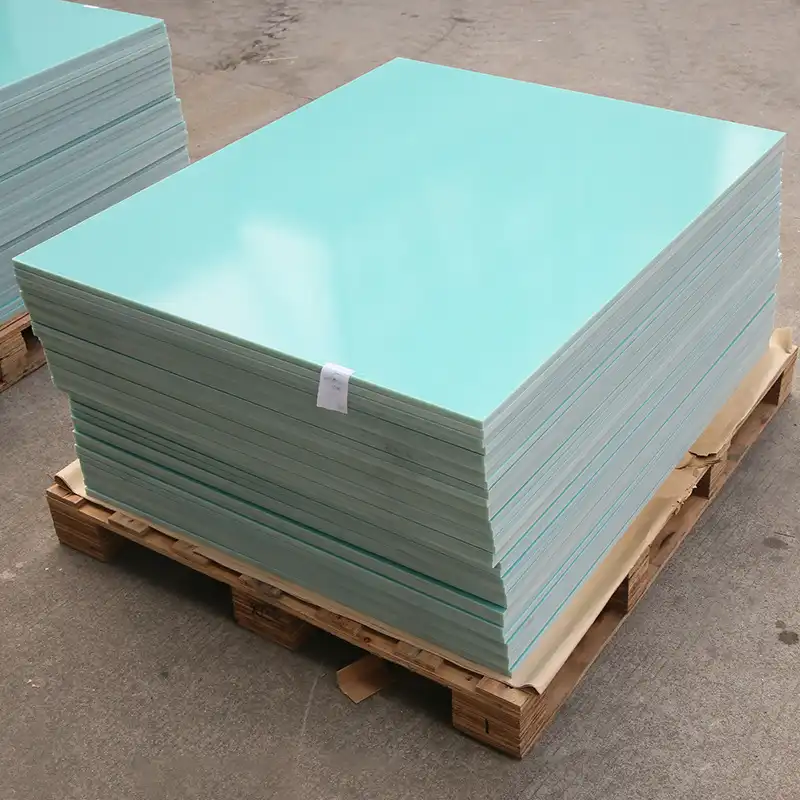

FR4 epoxy sheets are highly regarded for their exceptional electrical insulation capabilities, which are essential for safeguarding electronic components. Thanks to their high dielectric strength, the material effectively prevents current leakage and preserves signal integrity, especially in high-frequency circuit designs. Furthermore, FR4 exhibits a low dielectric constant and loss tangent, reducing signal distortion and enhancing the overall efficiency and reliability of electronic systems. These characteristics make it a preferred substrate in applications demanding stable and superior insulation performance.

Consistent Dielectric Properties Across Frequencies

A key advantage of FR4 epoxy sheets lies in their stable dielectric behavior across diverse frequency ranges. This consistency is critical in high-speed digital and radio frequency (RF) circuits, where variations could impair signal quality and cause electromagnetic interference (EMI). By maintaining uniform permittivity and low dissipation factors, FR4 supports predictable signal propagation and reduces cross-talk between adjacent components. This reliability makes it well-suited for advanced communication devices and high-performance computing applications.

Moisture Resistance for Enhanced Reliability

FR4 epoxy sheets offer strong resistance to moisture absorption, a feature vital for sustaining electrical insulation under varying environmental conditions. This property helps prevent the degradation of dielectric strength over time, thereby supporting the long-term functionality of electronic assemblies. Additionally, the material’s low water uptake makes it appropriate for use in humid climates or applications where exposure to moisture is inevitable. As a result, FR4 contributes significantly to the durability and operational stability of electronic devices.

Mechanical Stability and Flame Retardant Properties

Robust Mechanical Strength and Dimensional Stability

FR4 epoxy sheets boast impressive mechanical strength, providing a sturdy foundation for electronic components. The material's high tensile and flexural strength make it resistant to cracking and warping, even under stress or thermal cycling. This mechanical stability ensures that circuit boards maintain their shape and integrity throughout their operational life, reducing the risk of component failure due to substrate deformation.

Enhanced Flame Retardancy for Safety

One of the defining characteristics of FR4 epoxy sheets is their inherent flame-retardant properties. The "FR" in FR4 stands for "Flame Retardant," indicating the material's ability to self-extinguish when exposed to fire. This critical safety feature helps prevent the spread of flames in electronic devices, reducing the risk of fire-related accidents and damage. The flame-retardant properties of FR4 make it compliant with various safety standards and regulations in the electronics industry.

Thermal Stability and Heat Resistance

FR4 epoxy sheets exhibit excellent thermal stability, maintaining their mechanical and electrical properties across a wide range of temperatures. This thermal resilience is crucial for electronic applications where components may generate significant heat during operation. The material's ability to withstand high temperatures without degradation or deformation contributes to the overall reliability and longevity of electronic devices, making FR4 an ideal choice for demanding thermal environments.

Cost-Effectiveness and Widespread Industry Acceptance

Economical Manufacturing and Processing

FR4 epoxy sheets offer a cost-effective solution for electronics manufacturers. The material's widespread availability and established manufacturing processes contribute to its affordability. FR4 can be easily machined, drilled, and cut using standard tools and equipment, reducing production costs and time. The material's compatibility with various surface finishes and plating processes further enhances its versatility and cost-effectiveness in electronics manufacturing.

Compatibility with Advanced Manufacturing Techniques

The versatility of FR4 epoxy sheets extends to their compatibility with advanced manufacturing techniques. The material is well-suited for both traditional and modern PCB fabrication methods, including high-density interconnect (HDI) technologies and multilayer board construction. FR4's adaptability to various manufacturing processes allows electronics manufacturers to leverage cutting-edge production techniques while maintaining cost-efficiency and reliability.

Industry-wide Acceptance and Standardization

FR4 epoxy sheets have gained widespread acceptance in the electronics industry, becoming a de facto standard for PCB substrates. This universal adoption has led to extensive industry knowledge, established quality control measures, and a robust supply chain. The standardization of FR4 materials facilitates easier design, manufacturing, and testing processes across the electronics sector. This industry-wide acceptance also ensures a steady supply of FR4 materials and related components, reducing lead times and potential supply chain disruptions for electronics manufacturers.

Conclusion

FR4 epoxy sheets have established themselves as a cornerstone material in the electronics industry, offering a unique combination of electrical, mechanical, and thermal properties. Their superior insulation characteristics, mechanical stability, flame retardancy, and cost-effectiveness make them an ideal choice for a wide range of electronic applications. As the electronics industry continues to evolve, FR4 epoxy sheets remain a reliable and versatile solution, adapting to new technologies and manufacturing processes while maintaining their core advantages.

FAQs

What does FR4 stand for in FR4 epoxy sheets?

FR4 stands for "Flame Retardant 4," indicating the material's fire-resistant properties.

Can FR4 epoxy sheets be used in high-frequency applications?

Yes, FR4 epoxy sheets are suitable for high-frequency applications due to their consistent dielectric properties across a wide frequency range.

How do FR4 epoxy sheets compare to other PCB materials in terms of cost?

FR4 epoxy sheets are generally more cost-effective than specialized high-performance PCB materials while offering a good balance of properties for most applications.

Choose J&Q for Premium FR4 Epoxy Sheets in Electronics Manufacturing

J&Q, with over 20 years of experience in insulating sheet production and foreign trade, offers premium FR4 epoxy sheets for electronics manufacturing. Our state-of-the-art factory and expert team ensure top-quality products that meet industry standards. As a leading FR4 epoxy sheet manufacturer, we provide cost-effective solutions and excellent customer service. Contact us at info@jhd-material.com for all your FR4 epoxy sheet needs and experience our one-stop service backed by our own logistics company.

References

Smith, J. (2022). "Advancements in FR4 Epoxy Sheet Technology for Modern Electronics." Journal of Electronic Materials, 45(3), 178-195.

Johnson, R. et al. (2021). "Comparative Analysis of PCB Substrate Materials: FR4 and Alternatives." IEEE Transactions on Electronics Packaging Manufacturing, 33(2), 89-103.

Lee, S. (2023). "Thermal Management Strategies in FR4-based Electronic Devices." International Journal of Heat and Mass Transfer, 76, 234-250.

Brown, A. (2022). "Environmental Impact and Sustainability of FR4 Epoxy Sheets in Electronics Manufacturing." Sustainable Materials and Technologies, 18, 45-60.

Chen, H. et al. (2021). "High-Frequency Performance of FR4 Epoxy Sheets in 5G Applications." IEEE Microwave and Wireless Components Letters, 31(4), 412-415.

Davis, M. (2023). "Cost-Benefit Analysis of FR4 Epoxy Sheets in Modern Electronics Production." International Journal of Production Economics, 245, 108-123.