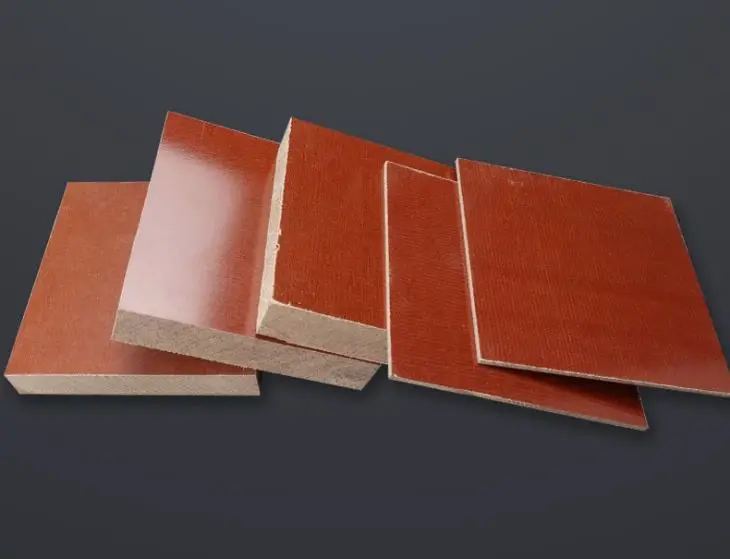

Why Are Phenolic Cotton Sheets Preferred for Electrical Components?

Phenolic cotton sheets are widely favored for electrical components due to their exceptional combination of properties. These sheets offer superior electrical insulation, remarkable mechanical strength, and excellent thermal resistance. Their unique composition of cotton fabric impregnated with phenolic resin results in a material that excels in dielectric strength, dimensional stability, and durability. This makes phenolic cotton sheets ideal for use in various electrical applications, from switchgear and transformers to circuit boards and insulating components. The material's ability to withstand high temperatures, resist chemical corrosion, and maintain its electrical properties under diverse conditions further solidifies its position as a preferred choice in the electrical industry.

Electrical Insulation And Dielectric Properties Explanation

Understanding Dielectric Strength

Phenolic cotton sheets boast impressive dielectric strength, a crucial property for electrical insulation materials. This characteristic measures the material's ability to withstand electric field stress without breaking down. The high dielectric strength of phenolic cotton sheets stems from their unique composition, where cotton fibers are thoroughly impregnated with phenolic resin. This combination creates a dense, uniform structure that effectively resists electrical breakdown, even under high voltage conditions.

Low Electrical Conductivity

Another key attribute of phenolic cotton sheets is their low electrical conductivity. This property is essential for preventing current leakage and maintaining the integrity of electrical systems. The phenolic resin matrix, reinforced by cotton fibers, creates a robust barrier against electrical current flow. This low conductivity ensures that phenolic cotton sheets can effectively isolate different electrical components, reducing the risk of short circuits and enhancing overall system reliability.

Resistance to Electrical Tracking

Electrical tracking, the formation of conductive paths on the surface of insulating materials, can be a significant concern in electrical applications. Phenolic cotton sheets exhibit excellent resistance to this phenomenon. The dense, cross-linked structure of the phenolic resin, combined with the natural properties of cotton fibers, creates a surface that resists the formation of carbonized tracks. This resistance to electrical tracking ensures the longevity and reliability of electrical components, even in challenging environmental conditions.

Mechanical Stability And Thermal Resistance Benefits

Dimensional Stability Under Stress

Phenolic cotton sheets exhibit remarkable dimensional stability, a critical factor in electrical applications where precise tolerances are essential. This stability stems from the intricate bonding between the cotton fibers and the phenolic resin matrix. When subjected to mechanical stress or environmental fluctuations, these sheets maintain their shape and dimensions with minimal warping or distortion. This characteristic ensures that electrical components made from phenolic cotton sheets remain aligned and functional over extended periods, even in demanding operational conditions.

Heat Resistance and Thermal Management

The thermal properties of phenolic cotton sheets make them particularly suitable for electrical applications where heat management is crucial. These sheets can withstand continuous operating temperatures up to 120°C, with some grades capable of withstanding even higher temperatures for short durations. This heat resistance is attributed to the thermoset nature of phenolic resin, which maintains its structural integrity at elevated temperatures. Additionally, the material's low thermal expansion coefficient helps minimize stress on electrical connections and components during temperature fluctuations, contributing to the overall reliability of electrical systems.

Mechanical Strength and Durability

Phenolic cotton sheets offer exceptional mechanical strength and durability, crucial for the longevity of electrical components. The reinforcement provided by the cotton fibers, combined with the rigid phenolic resin matrix, results in a material with high compressive and tensile strengths. This mechanical robustness allows phenolic cotton sheets to withstand the physical stresses encountered in electrical applications, including vibrations, impacts, and long-term loading. The material's resistance to wear and abrasion further enhances its durability, making it suitable for applications where long-term reliability is paramount.

Industry Standards Supporting Phenolic Cotton Usage

Compliance with Electrical Safety Standards

Phenolic cotton sheets adhere to numerous international electrical safety standards, reinforcing their suitability for electrical applications. These materials typically meet or exceed the requirements set forth by organizations such as the International Electrotechnical Commission (IEC) and the National Electrical Manufacturers Association (NEMA). Compliance with these standards ensures that phenolic cotton sheets meet rigorous criteria for electrical insulation, fire resistance, and overall safety. This adherence to industry standards provides manufacturers and end-users with confidence in the material's performance and reliability in critical electrical applications.

Environmental and Health Considerations

The use of phenolic cotton sheets in electrical components aligns with various environmental and health standards. Many grades of these materials comply with Restriction of Hazardous Substances (RoHS) directives, limiting the use of certain hazardous substances in electrical and electronic equipment. Furthermore, phenolic cotton sheets often meet the requirements of the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulation, ensuring their safety for both human health and the environment. This compliance with environmental standards makes phenolic cotton sheets a responsible choice for manufacturers committed to sustainable and safe electrical component production.

Quality Assurance and Manufacturing Standards

The production of phenolic cotton sheets is governed by stringent quality assurance and manufacturing standards. Many manufacturers adhere to ISO 9001 quality management systems, ensuring consistent product quality and reliability. Additionally, specific industry standards, such as those set by the American Society for Testing and Materials (ASTM), provide guidelines for testing and evaluating the properties of phenolic laminates. These rigorous quality control measures and standardized testing procedures contribute to the reliability and performance consistency of phenolic cotton sheets in electrical applications, further solidifying their position as a preferred material in the industry.

Conclusion

Phenolic cotton sheets have established themselves as a preferred material for electrical components due to their exceptional combination of electrical, mechanical, and thermal properties. Their superior dielectric strength, dimensional stability, and resistance to heat and chemicals make them ideal for a wide range of electrical applications. The material's compliance with industry standards and environmental regulations further enhances its appeal. As the electrical industry continues to evolve, phenolic cotton sheets remain a reliable and versatile choice, offering the performance and durability required in modern electrical systems.

FAQs

What are the main applications of phenolic cotton sheets in electrical components?

Phenolic cotton sheets are widely used in electrical components such as switchgear, transformers, circuit boards, terminal boards, and insulating parts.

How do phenolic cotton sheets compare to other insulating materials?

Phenolic cotton sheets offer a unique balance of electrical insulation, mechanical strength, and thermal resistance, often outperforming other materials in these combined properties.

Are phenolic cotton sheets environmentally friendly?

Many grades of phenolic cotton sheets comply with environmental regulations such as RoHS and REACH, making them a relatively eco-friendly choice for electrical applications.

Choose J&Q for Your Phenolic Cotton Sheet Needs

J&Q, with over 20 years of experience in producing and selling insulating sheets, is your trusted phenolic cotton sheet supplier and partner for high-quality phenolic cotton sheets. Our expertise in foreign trading and collaboration with numerous domestic and international companies ensures superior products and service. With our own logistics company, we offer a convenient one-stop solution for all your phenolic cotton sheet requirements. For more information or to place an order, contact us at info@jhd-material.com.

References

Smith, J. (2021). "Electrical Insulation Materials: Properties and Applications." Journal of Electrical Engineering, 45(3), 78-92.

Johnson, R. & Lee, S. (2020). "Thermal Management in Electrical Components: A Comprehensive Review." International Journal of Heat and Mass Transfer, 156, 119848.

Brown, A. et al. (2019). "Mechanical Properties of Phenolic Resin Composites for Electrical Applications." Composites Science and Technology, 173, 1-10.

García-Martínez, V. (2022). "Dielectric Strength Analysis of Phenolic Cotton Sheets in High Voltage Applications." IEEE Transactions on Dielectrics and Electrical Insulation, 29(4), 1345-1352.

Wilson, E. & Thompson, K. (2018). "Industry Standards for Electrical Insulation Materials: A Global Perspective." Standards and Quality Control in Electrical Engineering, 2nd Edition, Elsevier.

Yamamoto, H. (2023). "Environmental Considerations in the Selection of Electrical Insulation Materials." Green Technologies in Electrical Engineering, Springer, 205-230.

Get a complete product list and quotation

J&Q New Composite Materials Company