Composition and Manufacturing Process of Phenolic Cotton Sheets

Raw Materials and Their Properties

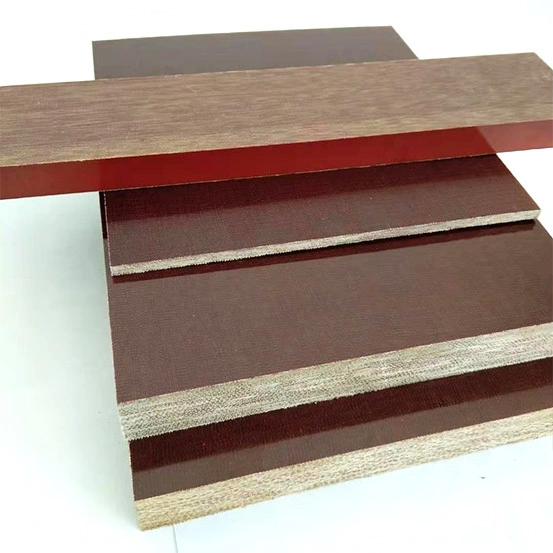

Phenolic cotton sheets are crafted from a carefully selected combination of materials. The primary components include:

- Cotton fabric: Provides a strong, flexible base with natural insulating properties

- Phenolic resin: Offers excellent electrical insulation and heat resistance

- Catalysts and additives: Enhance specific properties like flame retardancy or moisture resistance

The synergy between these materials results in a product that boasts superior electrical and mechanical characteristics, making it ideal for use in demanding electrical applications.Manufacturing Techniques

The production of phenolic cotton sheets involves a meticulous process that ensures consistent quality and performance. Key steps in the manufacturing process include:

- Impregnation: Cotton fabric is saturated with liquid phenolic resin

- Drying: Excess resin is removed, and the material is partially cured

- Layering: Multiple sheets are stacked to achieve the desired thickness

- Compression molding: Heat and pressure are applied to fully cure the resin

- Finishing: Sheets are cut, trimmed, and polished to meet specific requirements

This carefully controlled process results in phenolic cotton sheets, also known as phenolic cotton cloth board, with uniform properties and excellent dimensional stability.Quality Control Measures

To ensure the highest standards of performance and reliability, manufacturers implement rigorous quality control measures throughout the production process. These may include:

- Raw material testing: Verifying the quality and consistency of cotton fabric and phenolic resin

- In-process monitoring: Checking temperature, pressure, and curing time during manufacturing

- Physical testing: Assessing mechanical properties such as tensile strength and flexural modulus

- Electrical testing: Evaluating insulation resistance, dielectric strength, and arc resistance

- Dimensional inspection: Ensuring sheets meet specified thickness and flatness tolerances

These comprehensive quality control measures guarantee that phenolic cotton sheets meet or exceed industry standards and customer expectations.Key Applications of Phenolic Cotton Sheets in Electrical Industries

Transformer and Switchgear Insulation

Phenolic cotton sheets play a vital role in the insulation of transformers and switchgear equipment. Their applications in this area include:

- Core insulation: Providing electrical separation between transformer windings and core

- Layer insulation: Insulating individual layers of windings in transformers

- Barrier insulation: Creating physical barriers between high-voltage components in switchgear

- Bushing insulation: Insulating bushing terminals and supporting structures

The high dielectric strength and thermal stability of phenolic cotton sheets make them ideal for these critical insulation applications, ensuring the safe and efficient operation of power distribution systems.Circuit Board Manufacturing

In the realm of electronic circuit boards, phenolic cotton sheets serve as an excellent base material. Their applications include:

- Printed circuit boards (PCBs): Providing a stable substrate for electronic components and conductive tracks

- Terminal boards: Creating robust mounting surfaces for electrical terminals and connectors

- Insulating panels: Serving as protective barriers in electrical control panels

The dimensional stability and machining properties of phenolic cotton sheets make them particularly suitable for these applications, allowing for precise component placement and reliable electrical connections.Motor and Generator Components

Phenolic cotton sheets find extensive use in the construction of electric motors and generators. Key applications include:

- Slot insulation: Lining motor and generator slots to prevent short circuits

- Phase separation: Providing insulation between different phases of windings

- End-turn insulation: Protecting end-turns of windings from mechanical and electrical stress

- Commutator insulation: Insulating commutator segments in DC motors

The combination of electrical insulation properties and mechanical strength makes phenolic cotton sheets an excellent choice for these demanding applications, contributing to the longevity and reliability of motor and generator systems.Advantages and Limitations of Phenolic Cotton Sheets

Electrical and Mechanical Benefits

Phenolic cotton sheets offer a range of advantages that make them indispensable in electrical applications:

- High dielectric strength: Excellent resistance to electrical breakdown

- Low dielectric loss: Minimal energy dissipation in alternating electric fields

- Good mechanical strength: Ability to withstand physical stresses and vibrations

- Dimensional stability: Maintains shape and size under varying environmental conditions

- Machinability: Easily cut, drilled, and shaped without compromising electrical properties

These benefits contribute to the overall performance and reliability of electrical systems, making phenolic cotton sheets, or phenolic cotton cloth board, a preferred choice for many applications.Thermal and Chemical Resistance

The thermal and chemical properties of phenolic cotton sheets further enhance their suitability for electrical applications:

- Heat resistance: Maintains insulating properties at elevated temperatures

- Low thermal expansion: Minimal dimensional changes with temperature fluctuations

- Flame retardancy: Inherent resistance to flame propagation

- Chemical resistance: Withstands exposure to oils, solvents, and mild acids

- Moisture resistance: Low water absorption, maintaining electrical properties in humid environments

These characteristics ensure that phenolic cotton sheets perform reliably under a wide range of operating conditions, contributing to the safety and longevity of electrical equipment.Limitations and Considerations

While phenolic cotton sheets offer numerous advantages, it's important to consider their limitations:

- Temperature limits: Performance may degrade at very high temperatures (typically above 150°C)

- Brittleness: Can become brittle over time, especially in high-temperature applications

- Color limitations: Generally available in limited colors, typically brown or black

- Environmental concerns: Some formulations may contain potentially harmful substances

- Cost: May be more expensive than some alternative insulating materials

Understanding these limitations allows engineers and designers to make informed decisions when selecting insulating materials for specific applications, ensuring optimal performance and longevity of electrical systems.Conclusion

Phenolic cotton sheets have established themselves as a cornerstone in electrical insulation, offering a unique blend of electrical, mechanical, and thermal properties. Their versatility in applications ranging from transformers and switchgear to circuit boards and motor components underscores their importance in the electrical industry. While they do have some limitations, the benefits of phenolic cotton sheets often outweigh these considerations in many critical applications. As the electrical industry continues to evolve, phenolic cotton sheets are likely to remain a vital component, adapting to new challenges and contributing to the safety, efficiency, and reliability of electrical systems worldwide.

Contact Us

Are you looking for high-quality phenolic cotton sheets for your electrical applications? With over 20 years of experience in producing and selling insulating sheets, we offer expert guidance and top-notch products to meet your specific needs. Contact us today at info@jhd-material.com to learn more about our products and how we can support your projects with our comprehensive solutions and logistics services.