Understanding Phenolic Cotton Sheet and Its Dielectric Properties

Composition and Manufacturing Process of Phenolic Cotton Sheet

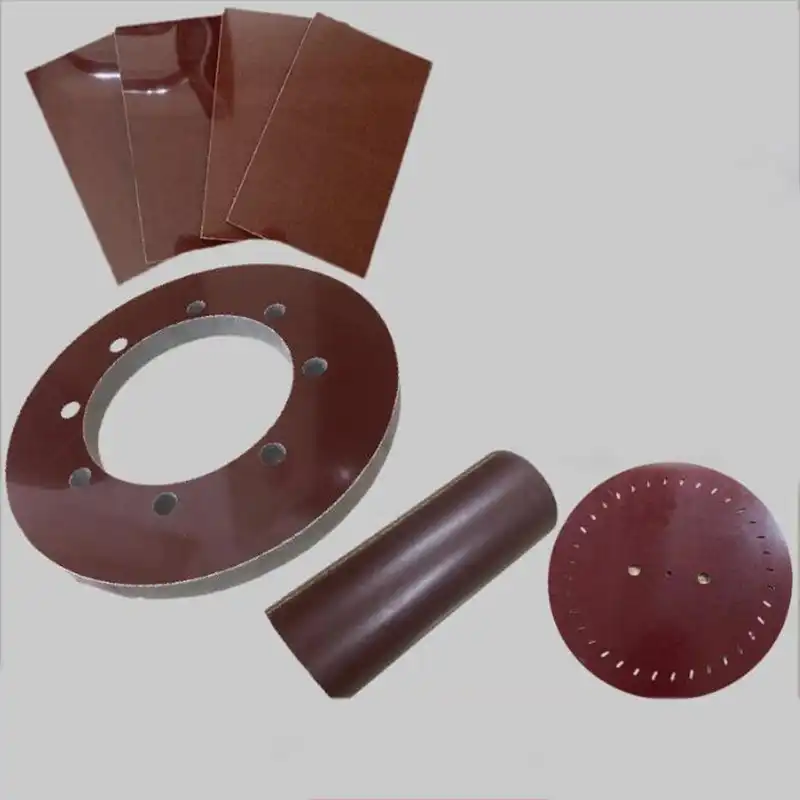

Phenolic cotton sheet is a composite material crafted from layers of cotton fabric impregnated with phenolic resin. The manufacturing process involves carefully layering the cotton fabric and applying the phenolic resin under controlled conditions. This combination results in a material that boasts both the strength of the cotton fibers and the insulating properties of the phenolic resin. The sheets undergo a curing process, typically involving heat and pressure, which further enhances their mechanical and electrical properties.

Factors Influencing the Dielectric Strength of Phenolic Cotton Sheet

Several factors contribute to the impressive dielectric strength of phenolic cotton sheet, also known as phenolic cotton cloth board. The quality and purity of the phenolic resin play a significant role, as does the density and weave of the cotton fabric. The manufacturing process, including the curing conditions and the uniformity of resin impregnation, also impacts the final dielectric properties. Environmental factors such as humidity and temperature can affect the dielectric strength in practical applications, though phenolic cotton sheets generally maintain their properties well under varying conditions.

Applications Leveraging the High Dielectric Strength of Phenolic Cotton Sheet

The exceptional dielectric strength of phenolic cotton sheet makes it a versatile material in various industries. It finds extensive use in electrical transformers, switchgear, and high-voltage equipment. The automotive and aerospace sectors utilize phenolic cotton sheets in components that require both electrical insulation and mechanical strength. In the electronics industry, these sheets serve as insulators in printed circuit boards and other sensitive components. The material's ability to maintain its properties under extreme conditions also makes it suitable for use in challenging environments, such as in oil and gas exploration equipment.

Comparative Analysis: Phenolic Cotton Sheet vs Other Insulating Materials

Dielectric Strength Comparison with Common Insulating Materials

When compared to other insulating materials, phenolic cotton sheet often emerges as a superior choice in terms of dielectric strength. For instance, while rubber typically has a dielectric strength of 10-20 kV/mm and most plastics range from 15-30 kV/mm, phenolic cotton sheet can achieve values of 20-40 kV/mm or even higher. This higher dielectric strength allows for thinner insulation layers without compromising safety, leading to more compact and efficient designs in electrical equipment.

Mechanical and Thermal Properties: A Holistic Comparison

Beyond dielectric strength, phenolic cotton sheet offers a balanced set of properties that set it apart from many alternatives. Its mechanical strength surpasses that of many pure plastic insulators, allowing it to withstand physical stress better. The material also exhibits good thermal stability, maintaining its properties at higher temperatures compared to some thermoplastics. This combination of electrical, mechanical, and thermal properties makes phenolic cotton sheet a versatile choice for applications where multiple performance criteria must be met simultaneously.

Cost-Effectiveness and Long-Term Performance Analysis

While the initial cost of phenolic cotton sheet may be higher than some basic insulating materials, its long-term performance often justifies the investment. The material's durability and resistance to environmental factors contribute to a longer lifespan in many applications. This longevity, coupled with the material's ability to maintain its properties over time, can result in lower maintenance and replacement costs. Additionally, the superior dielectric strength allows for more efficient designs, potentially reducing the overall material requirements in certain applications.

Innovations and Future Trends in Phenolic Cotton Sheet Technology

Advancements in Manufacturing Techniques for Enhanced Dielectric Properties

Recent innovations in the production of phenolic cotton sheet, also known as phenolic cotton cloth board, focus on enhancing its already impressive dielectric properties. Advanced impregnation techniques ensure more uniform distribution of the phenolic resin throughout the cotton fabric, leading to more consistent and potentially higher dielectric strength. Some manufacturers are experimenting with nano-additives that can further boost the material's insulating capabilities without compromising its mechanical properties. These advancements promise to push the boundaries of what's possible with phenolic cotton sheet insulation.

Emerging Applications in High-Tech and Renewable Energy Sectors

The unique properties of phenolic cotton sheet are finding new applications in cutting-edge technologies. In the rapidly growing renewable energy sector, these materials are being used in solar panel components and wind turbine electrical systems, where their combination of electrical insulation and durability is particularly valuable. The aerospace industry is exploring the use of phenolic cotton sheets in next-generation aircraft electrical systems, taking advantage of the material's light weight and high performance. As electric vehicles become more prevalent, phenolic cotton sheets are playing a crucial role in battery insulation and power distribution components.

Environmental Considerations and Sustainable Manufacturing Practices

As environmental concerns take center stage in industrial practices, the phenolic cotton sheet industry is adapting to meet sustainability challenges. Research is underway to develop bio-based phenolic resins that could reduce the environmental impact of production while maintaining or even improving performance. Some manufacturers are implementing closed-loop systems to minimize waste and recover resources during the production process. Additionally, efforts are being made to improve the recyclability of phenolic cotton sheets at the end of their lifecycle, potentially opening up new avenues for material recovery and reuse.

Conclusion

Phenolic cotton sheet stands out as a superior insulating material, particularly when considering its exceptional dielectric strength. Its unique combination of electrical, mechanical, and thermal properties makes it an invaluable component in various high-performance applications across multiple industries. As technology advances and environmental concerns grow, the ongoing innovations in phenolic cotton sheet manufacturing and applications ensure its continued relevance and importance in the field of electrical insulation. The material's versatility and reliability position it as a key player in the development of next-generation electrical and electronic systems.

Contact Us

For more information about our high-quality phenolic cotton sheets and how they can benefit your projects, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect insulation solution for your specific needs.