Understanding FR4 Epoxy Insulation Boards

Composition and Manufacturing Process

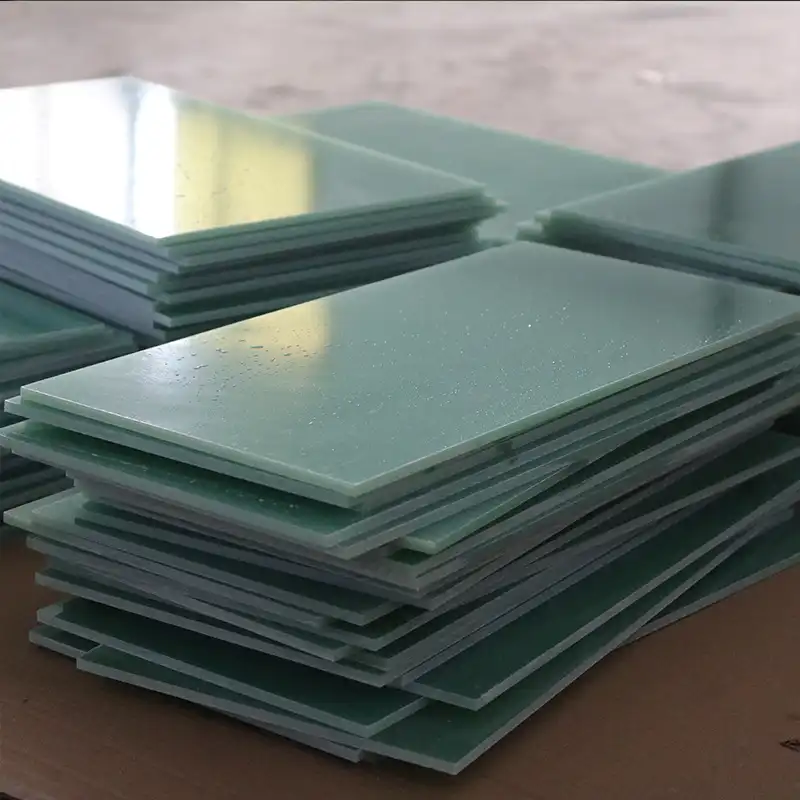

FR4 epoxy insulation boards are composite materials consisting of woven fiberglass cloth impregnated with epoxy resin. The manufacturing process involves layering multiple sheets of fiberglass fabric and saturating them with epoxy resin. This combination is then subjected to heat and pressure, resulting in a rigid, flame-retardant laminate. The "FR" in FR4 stands for "flame retardant," indicating the material's ability to resist combustion.

Key Properties of FR4 Epoxy Sheets

FR4 epoxy sheets boast an impressive array of properties that make them suitable for various electrical applications. These include high dielectric strength, low moisture absorption, excellent dimensional stability, and good mechanical strength. The material also exhibits remarkable heat resistance, with a glass transition temperature (Tg) typically ranging from 130°C to 180°C, depending on the specific formulation.

Advantages Over Other Insulating Materials

Compared to other insulating materials, FR4 epoxy sheets offer several advantages. They provide superior electrical insulation properties, better mechanical strength, and enhanced thermal stability. Unlike some traditional insulating materials, FR4 epoxy boards maintain their properties across a wide range of temperatures and environmental conditions. This versatility, combined with their flame-retardant characteristics, makes them a preferred choice in many electrical applications where safety and reliability are paramount.

Detailed Analysis of Top 5 Electrical Applications

Printed Circuit Boards (PCBs)

Printed circuit boards represent the most prevalent application of FR4 epoxy sheets in the electrical industry. The material's excellent dielectric properties and dimensional stability make it an ideal substrate for PCBs. FR4 epoxy boards provide a robust foundation for etching copper traces and mounting electronic components. Their low moisture absorption helps prevent short circuits and ensures the longevity of the PCB. Moreover, the flame-retardant nature of FR4 enhances the safety of electronic devices, particularly in high-power applications.

Electrical Insulation Panels

FR4 epoxy sheets are widely used as electrical insulation panels in various equipment and enclosures. These panels act as barriers between different electrical components, preventing current leakage and short circuits. The high dielectric strength of FR4 epoxy boards allows them to withstand significant voltage differences, making them suitable for both low and medium-voltage applications. Their mechanical durability also ensures that the insulation panels can withstand physical stress and vibrations commonly encountered in electrical systems.

Switchgear Components

In switchgear assemblies, FR4 epoxy insulation boards play a crucial role in ensuring safe and reliable operation. They are used to fabricate arc chutes, phase barriers, and insulating supports within switchgear enclosures. The material's excellent arc resistance and flame-retardant properties make it particularly suitable for these applications, where electrical arcing can occur during switching operations. FR4 epoxy sheets help contain and extinguish arcs, preventing damage to surrounding components and enhancing the overall safety of the switchgear.

Transformer Insulation

Transformers rely on effective insulation to maintain their efficiency and prevent short circuits between windings. FR4 epoxy sheets are employed in various transformer components, including winding insulation, layer insulation, and end insulation. The material's high dielectric strength and thermal stability make it well-suited for this application, as it can withstand the heat generated during transformer operation. Additionally, the low moisture absorption of FR4 epoxy boards helps maintain consistent insulation properties, even in humid environments.

High-Voltage Bushings

High-voltage bushings, which are used to safely pass conductors through grounded barriers, often incorporate FR4 epoxy insulation boards. These boards serve as insulating barriers within the bushing structure, helping to manage electric field distribution and prevent flashovers. The excellent dielectric properties and dimensional stability of FR4 epoxy sheets ensure reliable performance in these critical components, which are essential for the safe operation of high-voltage equipment in substations and power distribution systems.

Future Trends and Innovations in FR4 Epoxy Insulation Boards

Advancements in Material Formulations

The field of FR4 epoxy insulation boards is witnessing continuous innovation in material formulations. Researchers are exploring ways to enhance the thermal and electrical properties of FR4 epoxy sheets, pushing the boundaries of their performance capabilities. New additives and resin systems are being developed to improve flame retardancy, increase glass transition temperatures, and reduce dielectric losses. These advancements aim to meet the growing demands of high-frequency and high-power applications in emerging technologies.

Integration with Smart Technologies

As the Internet of Things (IoT) and smart grid technologies continue to evolve, FR4 epoxy insulation boards are being adapted to support these advancements. Manufacturers are exploring ways to integrate sensors and communication modules directly into FR4 epoxy sheets, creating smart insulation systems that can monitor their own condition and provide real-time data on electrical equipment performance. This integration has the potential to revolutionize predictive maintenance and enhance the overall reliability of electrical systems.

Sustainability and Environmental Considerations

The electrical industry is increasingly focused on sustainability, and this trend is influencing the development of FR4 epoxy insulation boards. Researchers are working on eco-friendly formulations that maintain the excellent properties of FR4 while reducing environmental impact. This includes exploring bio-based epoxy resins, developing recycling techniques for end-of-life FR4 products, and optimizing manufacturing processes to minimize waste and energy consumption. As environmental regulations become more stringent, these sustainable innovations in FR4 epoxy sheets will likely gain significant traction in the market.

Conclusion

FR4 epoxy insulation boards have proven to be invaluable in a wide range of electrical applications, from printed circuit boards to high-voltage bushings. Their unique combination of properties, including high dielectric strength, flame retardancy, and dimensional stability, makes them an essential material in modern electrical systems. As technology continues to advance, FR4 epoxy sheets are evolving to meet new challenges, with ongoing research focusing on enhancing their performance, integrating smart features, and improving sustainability. The versatility and reliability of FR4 epoxy insulation boards ensure their continued importance in shaping the future of electrical engineering and power distribution.

Contact Us

For more information about our FR4 epoxy insulation boards and how they can benefit your electrical applications, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect insulation solution for your specific needs.