Understanding Phenolic Cotton Sheets

Composition and Manufacturing Process

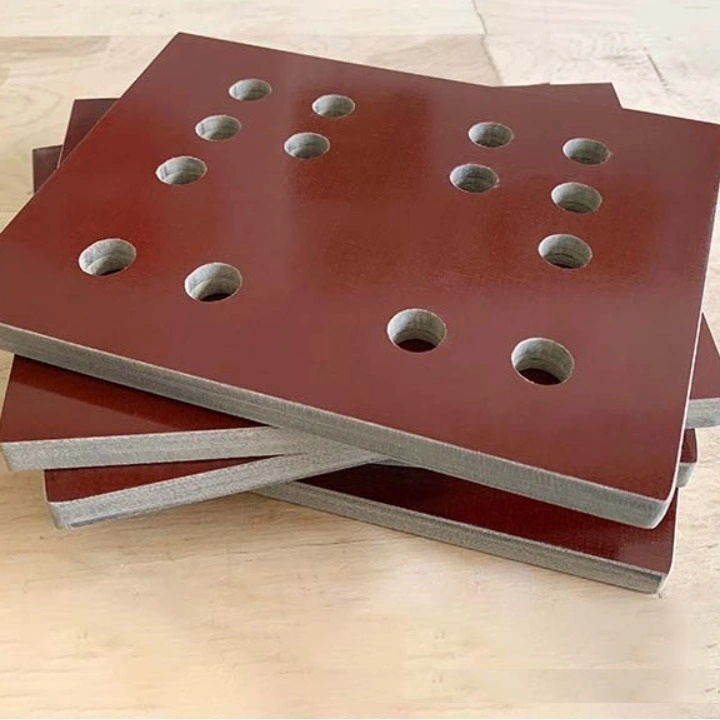

Phenolic cotton sheets are crafted through a meticulous process that involves impregnating cotton fabric with phenolic resin. This combination results in a material that boasts both the flexibility of cotton and the fire-resistant qualities of phenolic compounds. The manufacturing process typically involves saturating cotton cloth with a phenolic resin solution, followed by careful drying and curing stages. This intricate procedure ensures that the phenolic resin thoroughly penetrates the cotton fibers, creating a uniform and highly effective flame-retardant material.

Chemical Structure and Properties

The chemical structure of phenolic cotton sheets, also known as phenolic cotton cloth board, plays a pivotal role in their flame-retardant capabilities. Phenolic resins, derived from phenol and formaldehyde, form a complex three-dimensional network when cured. This network encapsulates the cotton fibers, creating a barrier that resists ignition and limits the spread of flames. The resulting material exhibits low thermal conductivity, high char yield, and minimal smoke production when exposed to fire, making it an ideal choice for safety-critical applications.

Comparative Advantages

When compared to other flame-retardant materials, phenolic cotton sheets stand out for several reasons. They offer a superior balance of fire resistance, mechanical strength, and electrical insulation properties. Unlike some synthetic flame-retardant materials, phenolic cotton sheets maintain their effectiveness over time and do not release harmful chemicals during combustion. This combination of durability, safety, and performance makes them a preferred choice in industries where fire safety cannot be compromised.

Flame Retardant Mechanisms

Heat Absorption and Dissipation

One of the primary flame-retardant mechanisms of phenolic cotton sheets is their ability to absorb and dissipate heat effectively. When exposed to high temperatures, the phenolic resin component undergoes endothermic reactions, absorbing significant amounts of heat energy. This process helps to lower the surface temperature of the material and delay ignition. Simultaneously, the cotton fibers, which have been impregnated with the phenolic resin, contribute to heat dissipation through their natural thermal properties, further enhancing the material's fire-resistant capabilities.

Char Formation

Another crucial aspect of the flame-retardant properties of phenolic cotton sheets is their propensity for char formation. When subjected to intense heat or direct flame, the phenolic resin component of the material undergoes a process called carbonization. This results in the formation of a protective char layer on the surface of the sheet. This char acts as an insulating barrier, shielding the underlying layers from further heat and oxygen exposure. The char layer's low thermal conductivity and high stability significantly impede the spread of fire and protect the integrity of the material beneath.

Oxygen Depletion

Phenolic cotton sheets also exhibit flame-retardant properties through a mechanism of oxygen depletion. As the material begins to decompose under high heat, it releases non-flammable gases that dilute the oxygen concentration in the immediate vicinity. This reduction in available oxygen creates an environment less conducive to sustaining combustion. The combination of char formation and oxygen depletion works synergistically to create a formidable defense against fire propagation, making phenolic cotton sheets highly effective in containing and suppressing flames.

Applications and Industry Standards

Aerospace and Aviation

In the aerospace and aviation sectors, where safety is of utmost importance, phenolic cotton sheets, also known as phenolic cotton cloth board, find extensive use. These materials are utilized in aircraft interiors, including wall panels, ceiling panels, and flooring systems. Their ability to meet stringent fire safety regulations, such as FAR 25.853, makes them indispensable in this industry. Phenolic cotton sheets not only provide excellent flame resistance but also contribute to weight reduction and noise attenuation in aircraft cabins, enhancing overall performance and passenger comfort.

Electrical and Electronics

The electrical and electronics industry heavily relies on phenolic cotton sheets for insulation purposes. These materials are used in the production of printed circuit boards, transformers, and various electrical components. Their combination of flame retardancy and excellent dielectric properties makes them ideal for applications where electrical safety is critical. Phenolic cotton cloth boards, a variant of phenolic cotton sheets, are particularly valued for their dimensional stability and resistance to heat distortion in electrical applications.

Construction and Building Materials

In the construction industry, phenolic cotton sheets play a vital role in enhancing building safety. They are incorporated into wall systems, ceiling tiles, and insulation materials to improve fire resistance in both residential and commercial structures. The use of these materials helps in meeting building codes and fire safety standards, providing crucial time for occupants to evacuate in the event of a fire. Additionally, the low smoke emission characteristic of phenolic cotton sheets is particularly beneficial in enclosed spaces, reducing the risk of smoke inhalation during fire incidents.

Conclusion

Phenolic cotton sheets represent a pinnacle in flame-retardant technology, offering unparalleled protection against fire hazards across various industries. Their unique composition, combining the strength of cotton with the fire-resistant properties of phenolic resins, results in a material that excels in safety-critical applications. From aerospace to construction, these versatile sheets continue to play a crucial role in safeguarding lives and assets. As fire safety standards evolve, phenolic cotton sheets remain at the forefront, consistently meeting and exceeding industry requirements, and reaffirming their status as an essential component in fire protection strategies.

Contact Us

For more information about our high-quality phenolic cotton sheets and how they can enhance the safety and performance of your projects, please don't hesitate to contact us. Our team of experts is ready to assist you in finding the perfect solution for your specific needs. Reach out to us at info@jhd-material.com to discuss how our products can benefit your business.