Understanding CE Phenolic Sheets and Their Applications

Composition and Properties of CE Phenolic Sheets

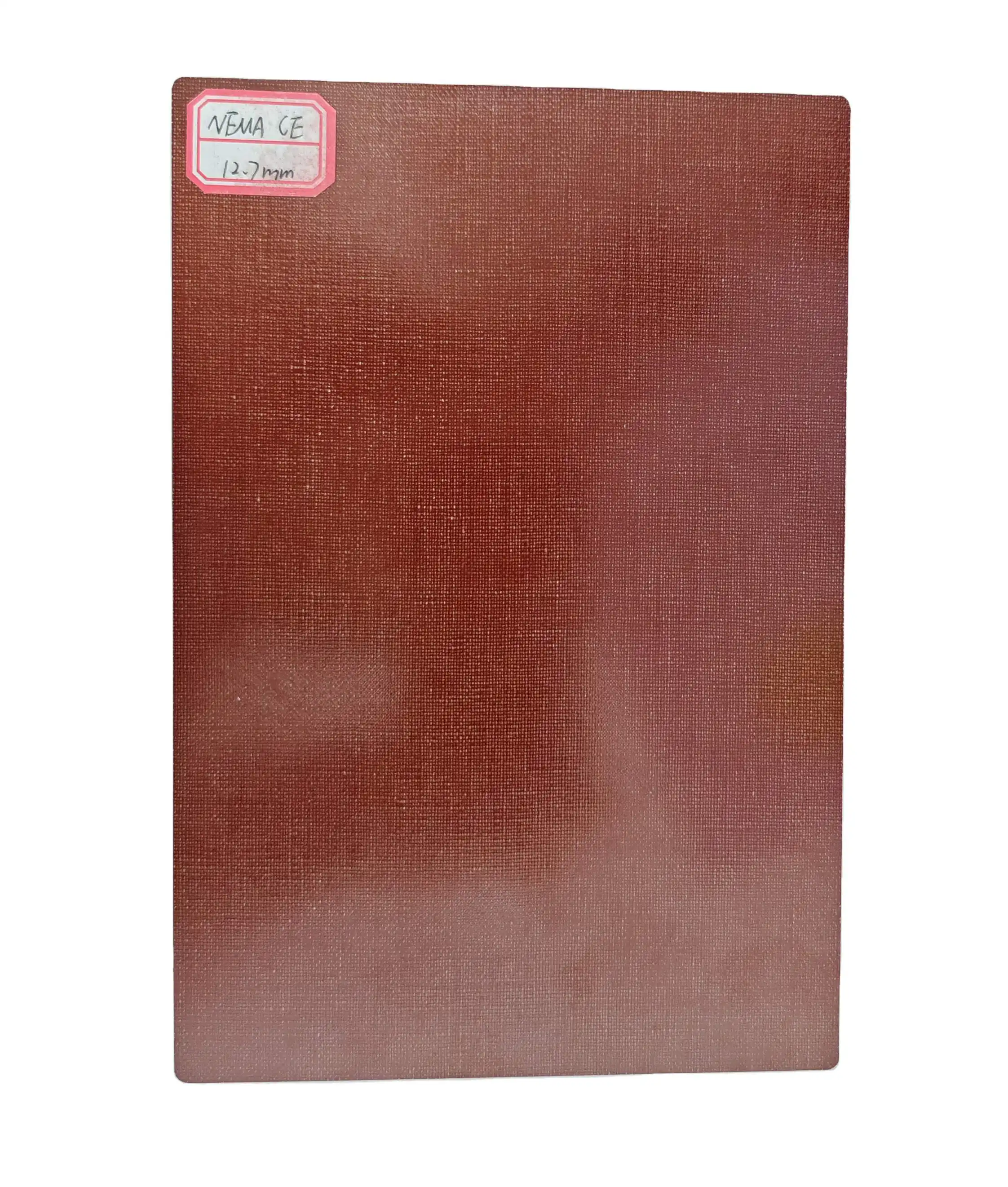

CE phenolic sheets are crafted from a sophisticated blend of cellulose paper and phenolic resin, resulting in a material that boasts remarkable strength and electrical insulation capabilities. The manufacturing process involves impregnating layers of cellulose paper with phenolic resin, which are then subjected to high pressure and temperature. This procedure yields a dense, homogeneous material with superior mechanical and thermal properties. CE phenolic sheets exhibit low moisture absorption, excellent dimensional stability, and high resistance to chemicals and heat, making them indispensable in various industrial applications.

Versatility in Industrial Applications

The versatility of CE phenolic sheets is truly remarkable, finding applications across a wide spectrum of industries. In the electrical sector, these sheets are utilized for manufacturing switchgear components, transformer parts, and insulating bushings. The automotive industry leverages CE phenolic sheets for producing brake pads, clutch facings, and various under-the-hood components that require high heat resistance. In the aerospace sector, these sheets contribute to the construction of aircraft interiors and structural components due to their lightweight yet robust nature. Furthermore, CE phenolic sheets are extensively used in the production of precision machined parts, gears, and bearings in mechanical engineering applications.

Advantages Over Other Insulating Materials

When compared to other insulating materials, CE phenolic sheets stand out for several reasons. Their superior electrical insulation properties make them an ideal choice for high-voltage applications. The sheets' exceptional mechanical strength allows for the creation of thin yet durable components, saving space and weight in various designs. Unlike some alternative materials, CE phenolic sheets maintain their properties across a wide temperature range, ensuring consistent performance in diverse environmental conditions. Additionally, their resistance to chemical degradation and moisture absorption contributes to a longer lifespan of the components made from these sheets, reducing the need for frequent replacements and maintenance.

RoHS and REACH Compliance: Importance and Impact

Overview of RoHS and REACH Regulations

RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) are two pivotal European Union regulations aimed at safeguarding human health and the environment. RoHS specifically targets the electronics industry, restricting the use of six hazardous materials: lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls, and polybrominated diphenyl ethers. REACH, on the other hand, has a broader scope, covering all chemical substances and their potential impacts on both human health and the environment. It places the responsibility on companies to identify and manage the risks associated with the substances they manufacture and market in the EU.

Significance of Compliance for Manufacturers and Consumers

Compliance with RoHS and REACH regulations is of paramount importance for manufacturers of CE phenolic sheets. It demonstrates their commitment to producing environmentally friendly and safe products, which is increasingly becoming a key factor in consumer decision-making. For manufacturers, adherence to these standards opens up markets in regions where compliance is mandatory, such as the European Union. It also provides a competitive edge in global markets where environmental consciousness is growing. Consumers benefit from the assurance that the products they use are free from harmful substances, contributing to a healthier living environment and reducing potential health risks associated with exposure to hazardous chemicals.

Environmental and Health Benefits of Compliance

The environmental and health benefits of RoHS and REACH compliance are substantial. By restricting the use of hazardous substances, these regulations contribute to reducing environmental pollution and mitigating the risks of these substances entering ecosystems. This is particularly crucial in the context of electronic waste management, where the proper disposal of products containing hazardous materials has been a significant challenge. From a health perspective, compliance ensures that workers involved in the manufacturing process, as well as end-users, are not exposed to harmful chemicals. This reduces the risk of long-term health issues associated with prolonged exposure to hazardous substances. Furthermore, the emphasis on safer alternatives encourages innovation in the development of more environmentally friendly materials and production processes.

Ensuring Compliance: Testing and Certification Process

Methods for Testing CE Phenolic Sheets

The testing process for CE phenolic sheets to ensure RoHS and REACH compliance is rigorous and multifaceted. It typically involves a combination of analytical techniques to detect and quantify the presence of restricted substances. X-ray fluorescence (XRF) spectroscopy is often used as an initial screening method due to its non-destructive nature and ability to quickly identify elements present in the material. For more precise quantification, techniques such as inductively coupled plasma mass spectrometry (ICP-MS) or atomic absorption spectroscopy (AAS) are employed. These methods can detect trace amounts of restricted elements with high accuracy. Gas chromatography-mass spectrometry (GC-MS) is utilized for detecting organic compounds, particularly relevant for REACH compliance. Additionally, wet chemical analysis techniques may be used to complement these instrumental methods, providing a comprehensive evaluation of the material's composition.

Certification Bodies and Their Role

Certification bodies play a crucial role in validating the compliance of CE phenolic sheets with RoHS and REACH regulations. These organizations are typically accredited by national or international authorities to perform testing and issue certifications. They maintain stringent quality control measures and stay updated with the latest regulatory requirements. The certification process involves not only testing the final product but also evaluating the manufacturer's quality management systems and supply chain controls. Reputable certification bodies such as TÜV, SGS, and Intertek are recognized globally for their expertise in this field. Their certifications provide credibility and assurance to both manufacturers and consumers, facilitating trade and enhancing product acceptance in various markets.

Maintaining Compliance: Ongoing Challenges and Solutions

Maintaining compliance with RoHS and REACH regulations is an ongoing process that presents several challenges for manufacturers of CE phenolic sheets. One significant challenge is staying abreast of evolving regulations, as new substances may be added to the restricted list or existing limits may be revised. To address this, manufacturers must implement robust systems for monitoring regulatory changes and quickly adapting their processes. Another challenge lies in supply chain management, ensuring that all raw materials and components used in production meet compliance standards. This necessitates careful supplier selection and regular audits. To overcome these challenges, many manufacturers are adopting advanced material tracking systems and implementing stringent quality control measures throughout their production process. Regular testing of both raw materials and finished products helps in maintaining consistent compliance. Additionally, investing in research and development to find safer alternatives for potentially restricted substances ensures long-term sustainability and compliance.

Conclusion

CE phenolic sheets' compliance with RoHS and REACH regulations underscores their safety and environmental friendliness. This compliance not only ensures the sheets meet stringent safety standards but also enhances their global marketability. As industries continue to prioritize sustainability and safety, CE phenolic sheets stand out as a reliable choice for various applications. Their unique properties, coupled with regulatory compliance, make them an invaluable material in today's environmentally conscious manufacturing landscape. The ongoing commitment to maintaining these standards reflects the industry's dedication to innovation and responsible production practices.

Contact Us

For more information about our CE phenolic sheets and their compliance with RoHS and REACH regulations, please don't hesitate to contact us. Our team of experts is ready to assist you with any questions or requirements you may have. Reach out to us at info@jhd-material.com to learn more about how our compliant CE phenolic sheets can benefit your projects and applications.