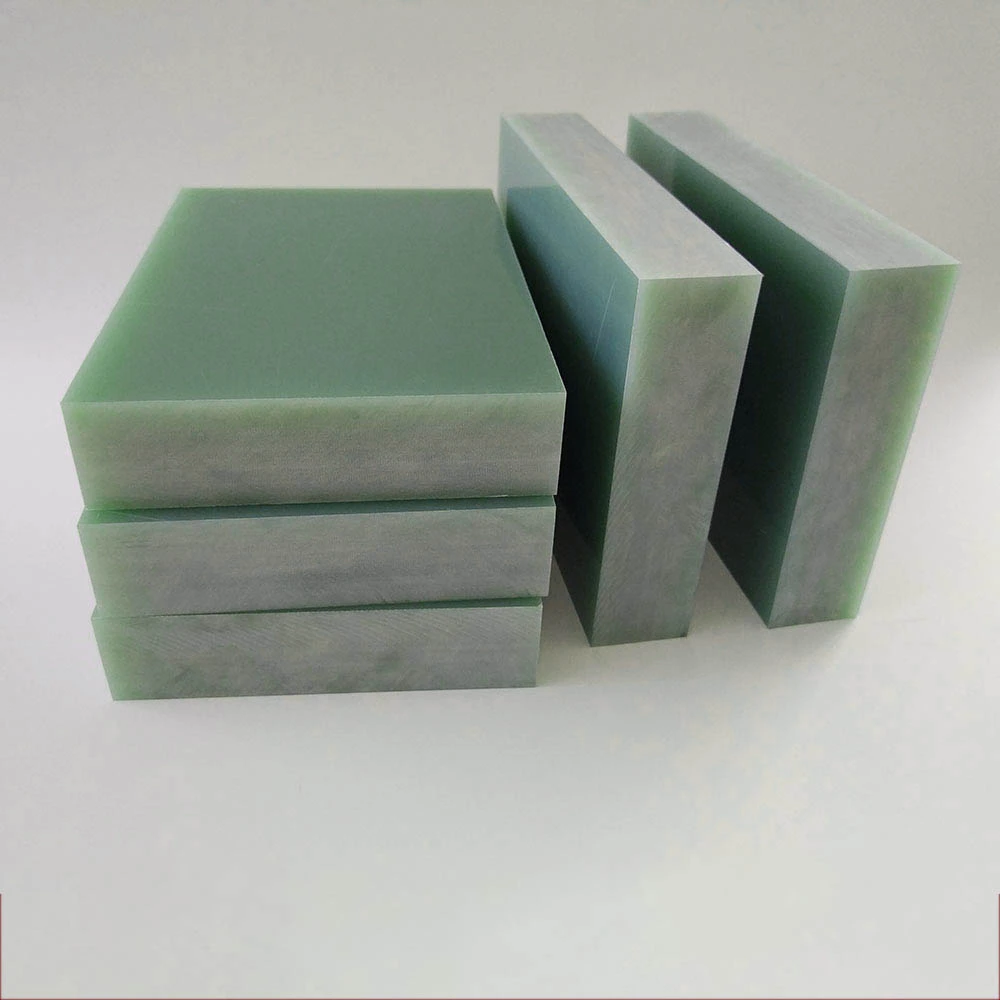

Why Is FR4 the Standard Material for PCB Substrates?

Exceptional Electrical Properties

FR4 epoxy sheets boast remarkable electrical properties that make them the go-to choice for PCB substrates. Their high dielectric strength ensures excellent insulation between conductive layers, preventing short circuits and maintaining signal integrity. The low dielectric constant of FR4 minimizes signal loss and crosstalk, crucial for high-frequency applications. Moreover, FR4's low dissipation factor contributes to reduced power loss, enhancing overall circuit efficiency.

Mechanical Strength and Durability

The robust mechanical properties of FR4 epoxy sheets contribute significantly to their popularity in PCB manufacturing. The glass fiber reinforcement provides exceptional tensile and flexural strength, allowing PCBs to withstand mechanical stress during assembly and operation. FR4's dimensional stability ensures that the board maintains its shape and size under varying environmental conditions, preserving the integrity of the circuit layout. This durability translates to longer-lasting electronic devices and reduced failure rates.

Thermal Resistance and Flame Retardancy

FR4 epoxy sheets exhibit excellent thermal resistance, maintaining their properties across a wide temperature range. This characteristic is crucial for electronics operating in challenging environments or generating substantial heat. The material's inherent flame-retardant properties, as indicated by the "FR" designation, provide an additional layer of safety. FR4's ability to self-extinguish in the event of a fire significantly reduces the risk of fire propagation in electronic devices, making it a preferred choice for applications where safety is paramount.

High-Performance Electrical Insulation in Circuit Design

Transformer and Motor Insulation

FR4 epoxy sheets play a vital role in electrical insulation for transformers and motors. Their high dielectric strength and excellent thermal properties make them ideal for separating conductive components and preventing electrical breakdown. In transformers, FR4 sheets are used to insulate primary and secondary windings, ensuring efficient power transfer while maintaining safety. For motors, FR4 provides insulation between stator windings and the motor housing, contributing to improved performance and longevity of the motor assembly.

Switchgear and Power Distribution Equipment

The exceptional insulating properties of FR4 epoxy sheets make them invaluable in switchgear and power distribution equipment. These sheets are used to create barriers between high-voltage components, preventing arcing and ensuring safe operation. FR4's ability to withstand high temperatures and resist moisture absorption contributes to the reliability of switchgear in various environmental conditions. The material's mechanical strength also allows for the creation of robust insulating structures that can withstand the physical stresses associated with power distribution systems.

High-Frequency Circuit Isolation

In high-frequency applications, such as RF and microwave circuits, FR4 epoxy sheets serve as effective isolators. Their low dielectric constant and loss tangent help minimize signal distortion and attenuation, crucial for maintaining signal integrity in these sensitive circuits. FR4 sheets are used to create physical barriers between different sections of a circuit, reducing electromagnetic interference and crosstalk. This isolation is particularly important in multi-layer PCB designs, where FR4 layers separate different signal planes, enabling complex circuit layouts while maintaining optimal performance.

FR4 in Consumer Devices, Automotive, and Industrial Equipment

Smart Devices and Wearable Technology

FR4 epoxy sheets have found extensive applications in the rapidly evolving world of smart devices and wearable technology. Their lightweight nature and excellent electrical properties make them ideal for compact, portable electronics. In smartphones, FR4-based PCBs house the intricate circuitry that powers advanced features. Wearable devices, such as fitness trackers and smartwatches, leverage FR4's durability and flexibility to create reliable, long-lasting products. The material's ability to withstand daily wear and tear while maintaining electrical performance is crucial in these consumer-oriented applications.

Automotive Electronics and Control Systems

The automotive industry heavily relies on FR4 epoxy sheets for various electronic components and control systems. From engine management units to infotainment systems, FR4-based PCBs form the foundation of modern vehicle electronics. The material's resistance to vibration, temperature fluctuations, and moisture makes it well-suited for the demanding automotive environment. FR4's flame-retardant properties also contribute to enhanced safety in vehicles. As the automotive industry moves towards electrification and autonomous driving, the role of FR4 in creating robust, reliable electronic systems becomes increasingly significant.

Industrial Automation and Control Equipment

Industrial automation and control equipment benefit greatly from the use of FR4 epoxy sheets. In programmable logic controllers (PLCs), human-machine interfaces (HMIs), and other industrial control devices, FR4-based PCBs provide a stable platform for complex circuitry. The material's ability to withstand harsh industrial environments, including exposure to chemicals and extreme temperatures, ensures the longevity of critical control systems. FR4's excellent insulating properties also contribute to the safety and reliability of industrial equipment, reducing the risk of electrical failures in high-stakes manufacturing and process control applications.

Conclusion

FR4 epoxy sheets have proven to be a cornerstone in the electronics industry, offering a unique combination of electrical, mechanical, and thermal properties. Their versatility shines through in applications ranging from PCB substrates to electrical insulation and structural components. As technology continues to advance, FR4 epoxy sheets will undoubtedly play a crucial role in shaping the future of electronics, enabling the development of more compact, efficient, and reliable devices across various sectors. The continued innovation in FR4 technology promises to unlock new possibilities in electronic design and manufacturing.

Contact Us

To learn more about our high-quality FR4 epoxy sheets and how they can benefit your electronic applications, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your needs.