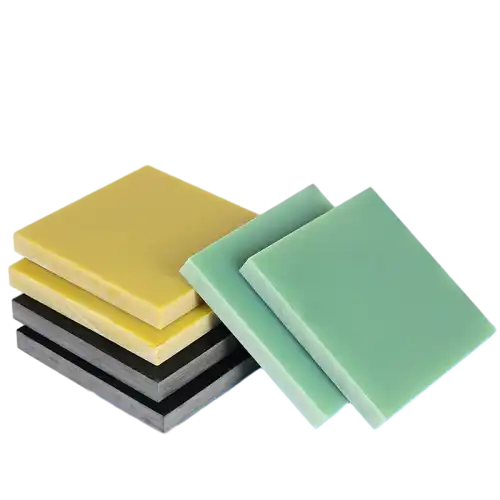

How Do Insulation Sheets Protect Electronic Components?

Electrical Isolation and Safety

Insulation sheets serve as formidable barriers against electrical current flow, effectively separating conductive elements within electronic devices. This isolation is paramount in preventing short circuits, which can lead to device failure or pose safety hazards. By creating a non-conductive layer between different components, insulation sheets allow for the safe coexistence of various voltage levels within a single device, enabling complex electronic systems to function reliably.

Thermal Management and Heat Dissipation

Beyond electrical isolation, insulation sheets play a pivotal role in thermal management. Many electronic components generate heat during operation, which can be detrimental to performance and longevity if not properly managed. Insulation sheets with specific thermal properties can help dissipate heat efficiently, directing it away from sensitive components. This thermal regulation is crucial in maintaining optimal operating temperatures, preventing overheating, and ensuring the longevity of electronic devices.

Protection Against Environmental Factors

Electronic components are often susceptible to environmental factors such as moisture, dust, and chemical contaminants. Insulation sheets act as protective barriers, shielding sensitive parts from these external threats. By creating a sealed environment, these sheets help maintain the integrity of electronic assemblies, preventing corrosion, oxidation, and other forms of degradation that can compromise device functionality. This protective role is particularly important in harsh operating conditions or outdoor applications where electronics are exposed to the elements.

Electrical and Thermal Properties Critical for Electronics

Dielectric Strength and Voltage Breakdown

The dielectric strength of an insulation sheet is a critical property that determines its ability to withstand high voltages without breaking down. This characteristic is measured in volts per unit thickness and indicates the maximum electric field the material can withstand before electrical breakdown occurs. High-quality insulation sheets boast superior dielectric strength, allowing them to maintain electrical isolation even under extreme voltage conditions. This property is particularly crucial in high-power electronics and power distribution systems where voltage spikes and surges are common occurrences.

Thermal Conductivity and Resistance

The thermal properties of insulation sheets are equally important in electronic applications. Thermal conductivity measures the material's ability to conduct heat, while thermal resistance indicates its capacity to resist heat flow. Depending on the specific application, engineers may choose insulation sheets with low thermal conductivity to prevent heat transfer between components, or materials with higher thermal conductivity to facilitate heat dissipation. Balancing these properties is essential in designing efficient thermal management solutions for electronic devices, ensuring optimal performance and reliability across various operating conditions.

Flame Retardancy and Fire Safety

In the realm of electronics, fire safety is paramount. Many insulation sheets are engineered with flame retardant properties to mitigate fire risks associated with electrical malfunctions. These materials are designed to self-extinguish or slow the spread of flames, providing crucial time for fire detection and suppression systems to activate. The flame retardancy of insulation sheets is typically classified according to standards such as UL94, which specifies the material's behavior when exposed to small-scale ignition sources. This property is particularly important in consumer electronics, aerospace applications, and industrial equipment where fire safety regulations are stringent.

Applications in PCBs, Switchgear, and Consumer Devices

Printed Circuit Board Insulation

In the realm of printed circuit boards (PCBs), insulation sheets serve as the foundation upon which electronic components are mounted and interconnected. These sheets, often made from materials like FR-4 (a glass-reinforced epoxy laminate), provide a stable, non-conductive substrate for copper traces and electronic components. The insulation properties of PCB materials are crucial in preventing short circuits between layers in multi-layer boards and ensuring signal integrity by minimizing crosstalk and electromagnetic interference. Advanced insulation materials for PCBs also offer improved thermal management capabilities, which is essential for high-density, high-performance electronic designs.

Switchgear and Power Distribution

Switchgear and power distribution systems rely heavily on insulation sheets to maintain safety and reliability in high-voltage environments. These sheets are used to isolate live components, prevent arcing, and provide structural support within electrical enclosures. Materials such as polyester films and specialty composites are chosen for their excellent dielectric properties and ability to withstand extreme temperatures and environmental conditions. In switchgear applications, insulation sheets must maintain their integrity over long periods, resisting degradation from electrical stress, thermal cycling, and environmental factors to ensure the continued safe operation of power distribution networks.

Consumer Electronics and Portable Devices

The miniaturization trend in consumer electronics has placed new demands on insulation materials. Thin, flexible insulation sheets are now essential in smartphones, tablets, and wearable devices where space is at a premium. These materials not only provide electrical isolation but also contribute to thermal management in compact designs where heat dissipation is challenging. Insulation sheets in consumer devices often serve multiple functions, such as providing electromagnetic interference (EMI) shielding or enhancing the device's water resistance. The ability to integrate these functionalities into thin, lightweight materials has been key to the development of increasingly sophisticated and compact electronic products.

Conclusion

Insulation sheets are indispensable components in modern electronics, playing a multifaceted role in ensuring the safety, reliability, and performance of a wide range of devices and systems. From providing crucial electrical isolation and thermal management to enhancing fire safety and environmental protection, these materials are at the forefront of electronic design and innovation. As technology continues to advance, the development of new insulation materials with enhanced properties will remain critical in meeting the evolving demands of the electronics industry, paving the way for more efficient, compact, and sophisticated electronic devices in the future.

FAQs

What are the primary functions of insulation sheets in electronics?

Insulation sheets primarily provide electrical isolation, thermal management, and protection against environmental factors in electronic devices.

How do insulation sheets contribute to the safety of electronic devices?

They prevent short circuits, manage heat dissipation, and often incorporate flame retardant properties to enhance fire safety.

Can insulation sheets improve the performance of electronic devices?

Yes, by managing heat and providing electrical isolation, insulation sheets can significantly enhance the reliability and longevity of electronic components.

Expert Insulation Sheet Solutions for Modern Electronics from J&Q

At J&Q, we leverage our two decades of experience in insulation sheet manufacturing to deliver cutting-edge solutions for the electronics industry. Our state-of-the-art factory produces high-quality insulation sheets tailored to meet the exacting demands of modern electronic applications. With our extensive expertise and global trading network, we offer unparalleled service and products. For top-tier insulation sheets that enhance the performance and reliability of your electronic devices, contact our expert team at info@jhd-material.com.

References

Smith, J. (2022). Advanced Insulation Materials in Electronics: A Comprehensive Review. Journal of Electronic Materials, 51(3), 1245-1260.

Chen, L., & Wang, X. (2021). Thermal Management Strategies for High-Power Electronics Using Innovative Insulation Sheets. IEEE Transactions on Components, Packaging and Manufacturing Technology, 11(4), 578-590.

Patel, R. (2023). The Evolution of Insulation Materials in Printed Circuit Board Design. Circuit World, 49(2), 89-103.

Thompson, E., & Garcia, M. (2022). Fire Safety in Consumer Electronics: The Role of Flame Retardant Insulation. Fire Technology, 58(1), 201-215.

Yamamoto, K. (2021). Dielectric Properties of Novel Insulation Materials for High-Voltage Applications. IEEE Electrical Insulation Magazine, 37(6), 7-15.

Lee, S., & Kim, H. (2023). Miniaturization Challenges in Portable Electronics: Innovative Approaches to Insulation. Journal of Microelectronics and Electronic Packaging, 20(2), 45-57.