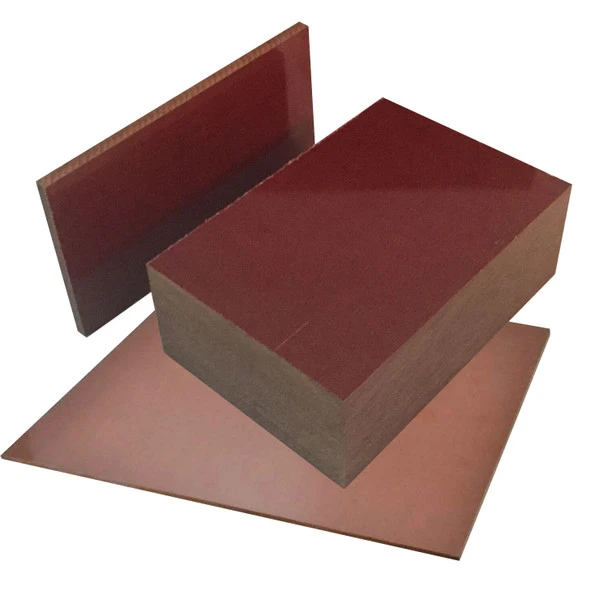

NEMA CE Sheet Industry Standards and Testing Procedures

NEMA CE sheet, a crucial component in electrical insulation and industrial applications, adheres to rigorous industry standards and undergoes comprehensive testing procedures to ensure quality, safety, and performance. The National Electrical Manufacturers Association (NEMA) establishes these standards, which encompass material composition, physical properties, electrical characteristics, and environmental resistance. Testing procedures involve a range of assessments, including mechanical strength tests, dielectric strength evaluations, flame resistance checks, and thermal stability analyses. These stringent measures guarantee that NEMA CE sheets meet the exacting requirements of various industries, from electrical equipment manufacturing to aerospace engineering.

What Standards Govern NEMA CE Sheet Quality and Safety?

NEMA LI 1 Standard: The Foundation

The NEMA LI 1 standard serves as the cornerstone for industrial laminated thermosetting products. It outlines specific requirements for NEMA CE sheets, covering essential aspects such as physical properties, electrical characteristics, and chemical resistance. This standard ensures consistency and reliability across different manufacturers and applications.

ASTM Standards: Complementary Guidelines

In addition to NEMA standards, ASTM International provides complementary guidelines for testing and evaluating NEMA CE sheets. These standards, such as ASTM D149 for dielectric strength and ASTM D570 for water absorption, offer detailed procedures for assessing specific material properties.

UL 94: Flame Retardancy Classification

The UL 94 standard, developed by Underwriters Laboratories, classifies the flame retardancy of NEMA CE sheets. This classification is crucial for applications where fire safety is paramount, ensuring that the material meets specific burn rates and self-extinguishing criteria.

Mechanical, Thermal, and Electrical Testing Methods

Mechanical Strength Evaluations

To validate durability and structural performance, NEMA CE sheets are subjected to a wide range of mechanical strength evaluations. These include tensile and flexural strength tests to measure resistance to pulling and bending forces, as well as impact resistance testing to assess toughness against sudden shocks. Additional analyses, such as compressive strength and hardness measurements, may also be conducted to ensure robustness. The results provide engineers with essential data for determining suitability in applications ranging from load-bearing supports to protective casings.

Thermal Stability Analyses

Thermal testing ensures that NEMA CE sheets perform reliably when exposed to challenging temperature conditions. Standard evaluations include heat deflection temperature (HDT) testing, which measures resistance to deformation under heat, and thermal expansion analysis to determine dimensional stability. Long-term thermal aging studies further evaluate material endurance over prolonged high-temperature exposure. These assessments are vital in industries such as automotive, aerospace, and power generation, where components frequently operate under fluctuating or extreme temperatures and require consistent mechanical and electrical performance.

Electrical Property Assessments

Since electrical insulation is a core application, NEMA CE sheets undergo extensive electrical property testing to guarantee safe use in demanding systems. Dielectric strength testing identifies the maximum voltage the material can withstand without failure, while surface and volume resistivity evaluations measure its resistance to current leakage. Dissipation factor testing provides insights into insulation efficiency by examining energy losses. Together, these assessments verify the reliability of NEMA CE sheets in preventing electrical breakdown, ensuring stable performance in motors, transformers, and switchgear assemblies.

Ensuring Compliance for Industrial and Electrical Applications

Quality Control Measures

Manufacturers of NEMA CE sheets apply rigorous quality control protocols at every stage of production to guarantee consistency and reliability. Raw materials are carefully inspected for compliance with specifications before use, and in-process checks monitor key parameters such as resin distribution and curing cycles. Final products undergo mechanical, electrical, and dimensional testing to verify performance. Advanced approaches like non-destructive evaluation and statistical process control are employed to identify irregularities, ensuring the finished sheets consistently meet established industrial and electrical standards.

Certification and Documentation

To validate compliance with recognized standards, NEMA CE sheets are tested and certified by accredited laboratories. Certification provides assurance to customers that the material delivers reliable electrical insulation, mechanical strength, and safety performance under demanding conditions. Supporting this process, manufacturers maintain detailed documentation including test results, certification records, and technical data sheets. These materials ensure full transparency, allowing end-users to verify conformity and trace quality. Such rigorous certification and documentation practices reinforce customer confidence and facilitate regulatory acceptance in critical applications.

Continuous Improvement and Innovation

As industrial and electrical applications advance, manufacturers continuously refine NEMA CE sheet technology to keep pace with evolving requirements. Investment in research and development enables improvements in material durability, electrical insulation, and resistance to environmental stress. New formulations, innovative curing methods, and enhanced testing techniques are regularly explored to boost performance. Feedback from end-users and industry trends also inform development efforts. This ongoing commitment to innovation ensures that NEMA CE sheets remain competitive, reliable, and fully compliant with both current and future standards.

Conclusion

NEMA CE sheets play a vital role in numerous industrial and electrical applications, and their performance is underpinned by rigorous standards and testing procedures. From mechanical strength to electrical insulation properties, every aspect of these materials is carefully evaluated to ensure reliability, safety, and longevity. As technology advances and industry requirements evolve, the standards and testing methods for NEMA CE sheets will continue to adapt, guaranteeing their relevance and effectiveness in an ever-changing industrial landscape.

FAQs

What are the key applications of NEMA CE sheets?

NEMA CE sheets are widely used in electrical insulation, printed circuit boards, and various industrial components requiring high mechanical strength and excellent electrical properties.

How often are NEMA standards updated?

NEMA regularly reviews and updates its standards to reflect technological advancements and changing industry needs. The frequency of updates can vary, but major revisions typically occur every few years.

Can NEMA CE sheets be customized for specific applications?

Yes, manufacturers can often tailor NEMA CE sheets to meet specific requirements, such as enhanced thermal resistance or improved chemical compatibility, while still adhering to core NEMA standards.

Experience the Quality of NEMA CE Sheets from J&Q

At J&Q, we bring over two decades of expertise in producing and supplying top-quality NEMA CE sheets. Our commitment to excellence, coupled with our extensive experience in international trade, ensures that we deliver products that meet and exceed industry standards. With our own logistics company, we offer a seamless, one-stop service experience. For more information about our NEMA CE sheets and how they can benefit your projects, contact us at info@jhd-material.com.

References

National Electrical Manufacturers Association. (2020). NEMA LI 1: Industrial Laminated Thermosetting Products.

ASTM International. (2019). ASTM D149: Standard Test Method for Dielectric Breakdown Voltage and Dielectric Strength of Solid Electrical Insulating Materials at Commercial Power Frequencies.

Underwriters Laboratories. (2018). UL 94: Standard for Tests for Flammability of Plastic Materials for Parts in Devices and Appliances.

IEEE. (2021). IEEE 1 Standard for General Principles for Temperature Limits in the Rating of Electrical Equipment and for the Evaluation of Electrical Insulation.

IEC. (2020). IEC 60243-1: Electrical strength of insulating materials - Test methods - Part 1: Tests at power frequencies.

ISO. (2019). ISO 178: Plastics - Determination of flexural properties.

Get a complete product list and quotation

J&Q New Composite Materials Company