How Does Dielectric Strength Influence Insulation Performance?

The Fundamentals of Dielectric Strength

Dielectric strength, typically measured in volts per unit thickness, defines the maximum electric field an insulation sheet can endure before experiencing electrical breakdown. This property is fundamental to the effectiveness of insulating materials, as it determines their ability to prevent current from passing through unintended paths. High dielectric strength ensures that electrical systems remain safe and functional, minimizing risks of short circuits, arcing, or equipment failure. Accurate knowledge of this parameter is essential when selecting insulation sheets for critical applications in electronics, power distribution, and industrial machinery.

Factors Affecting Dielectric Strength

The dielectric strength of insulation sheets is influenced by multiple factors. Material composition, including chemical formulation and physical structure, significantly affects the voltage the material can withstand. Thickness is also crucial, with thicker sheets generally offering higher dielectric strength. Environmental conditions, such as elevated temperatures and humidity, can reduce performance, while surface conditions like contamination, roughness, or irregularities may create localized weak points. Understanding these variables allows engineers to anticipate potential risks and choose materials that maintain reliable insulation performance under diverse operational conditions.

Importance of Dielectric Strength in Insulation Design

Dielectric strength plays a central role in designing effective insulation systems. Engineers must evaluate the maximum voltage levels that insulation sheets will encounter and select materials capable of withstanding those stresses without failure. Proper consideration of dielectric strength ensures long-term system reliability, reduces the likelihood of electrical faults, and minimizes maintenance costs. Incorporating materials with adequate dielectric properties also enhances overall performance, safety, and durability of electrical equipment, making this parameter a critical factor in industrial, aerospace, and high-voltage applications.

Measurement Techniques and Industry Standards

Common Dielectric Strength Testing Methods

Accurate measurement of dielectric strength is essential for quality control and material selection. Several testing methods are commonly used in the industry:

- ASTM D149: This standard test method involves applying an increasing voltage across the insulation sheet until breakdown occurs.

- IEC 60243: Similar to ASTM D149, this international standard provides guidelines for testing dielectric strength under various conditions.

- Short-time test: A rapidly increasing voltage is applied to the sample until breakdown occurs, providing a quick assessment of dielectric strength.

- Step-by-step test: The voltage is increased in steps, with each step maintained for a specified duration, allowing for a more thorough evaluation of the material's performance under sustained electrical stress.

Industry Standards for Dielectric Strength

Various industry standards govern the dielectric strength requirements for insulation sheets in different applications:

- IEEE Std 43-2013: This standard provides guidelines for testing the insulation resistance of rotating machinery.

- IEC 60085: Establishes thermal classification and evaluation methods for electrical insulation materials.

- UL 746A: Outlines the requirements for polymeric materials used in electrical equipment, including dielectric strength testing.

- NEMA LI 1: Specifies the properties and performance requirements for industrial laminated thermosetting products, including dielectric strength.

Interpreting Dielectric Strength Test Results

Interpreting dielectric strength test results requires consideration of various factors:

- Statistical analysis: Multiple samples should be tested to account for material variability and ensure reliable results.

- Environmental conditions: Test results may vary depending on temperature, humidity, and atmospheric pressure during testing.

- Breakdown mechanism: Understanding whether the breakdown occurred through the bulk material or along the surface can provide insights into potential weaknesses in the insulation design.

- Safety factors: When applying test results to real-world applications, appropriate safety factors should be used to account for aging, environmental stresses, and other factors that may affect long-term performance.

Applications in High-Performance Electrical Systems

Power Generation and Distribution

In power generation and distribution systems, insulation sheets with high dielectric strength are crucial for ensuring safe and efficient operation:

- Transformer insulation: High-voltage transformers require insulation materials with exceptional dielectric strength to prevent electrical breakdown between windings and core components.

- Switchgear: Insulation sheets are used in medium and high-voltage switchgear to provide electrical isolation between conductive parts and maintain safe clearances.

- Busbar insulation: In power distribution systems, insulation sheets with high dielectric strength are used to insulate busbars, preventing short circuits and ensuring personnel safety.

- Cable terminations: Insulation materials with excellent dielectric properties are essential for cable terminations in high-voltage applications, preventing partial discharges and electrical treeing.

Electronics and Semiconductor Manufacturing

The electronics and semiconductor industries rely on insulation sheets with precise dielectric properties:

- Printed circuit boards: Insulation materials used in PCB substrates must have consistent dielectric strength to maintain signal integrity and prevent electrical interference between layers.

- Semiconductor packaging: High-performance insulation sheets are used in semiconductor packaging to provide electrical isolation and thermal management.

- Test and measurement equipment: Precision instruments for testing electronic components require insulation materials with stable dielectric properties to ensure accurate measurements.

- Electrostatic discharge (ESD) protection: Insulation sheets with controlled dielectric strength are used in ESD-sensitive environments to prevent damage to sensitive electronic components.

Aerospace and Defense Applications

The aerospace and defense sectors demand insulation materials with exceptional dielectric strength and reliability:

- Aircraft wiring systems: Insulation sheets used in aircraft electrical systems must maintain their dielectric properties under extreme temperature and pressure conditions.

- Satellite components: Space-grade insulation materials with high dielectric strength are essential for protecting sensitive electronic equipment from the harsh space environment.

- Radar systems: Insulation sheets with precise dielectric properties are used in radar antennas and waveguides to maintain signal integrity and prevent interference.

- Military communications equipment: Ruggedized insulation materials with high dielectric strength are crucial for ensuring the reliability of military communications systems in demanding operational environments.

Conclusion

Understanding dielectric strength is paramount for the effective design and implementation of industrial laminates, particularly insulation sheets. This property not only ensures the safety and reliability of electrical systems but also plays a crucial role in optimizing performance across various applications. By considering factors such as material composition, environmental conditions, and industry standards, engineers and manufacturers can select the most appropriate insulation materials for their specific needs. As technology advances and electrical systems become more complex, the importance of dielectric strength in industrial laminates will continue to grow, driving innovation in insulation materials and testing methodologies.

FAQs

What is the importance of dielectric strength in insulation sheets?

Dielectric strength is crucial for determining the maximum electric field an insulation sheet can withstand without breaking down, ensuring safety and reliability in electrical systems.

How is dielectric strength measured?

Dielectric strength is typically measured using standardized tests like ASTM D149 or IEC 60243, which involve applying increasing voltage across the insulation sheet until breakdown occurs.

What factors can affect the dielectric strength of insulation sheets?

Factors affecting dielectric strength include material composition, thickness, temperature, humidity, and surface conditions of the insulation sheet.

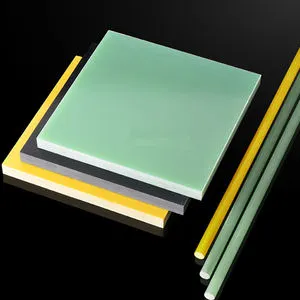

Expert Insulation Sheet Solutions for Industrial Laminates from J&Q

At J&Q, we leverage our extensive experience in producing and selling high-quality insulation sheets to provide innovative solutions for industrial laminates. Our factory specializes in manufacturing insulation materials with optimized dielectric strength, ensuring superior performance in various applications. As a leading manufacturer, we offer customized solutions tailored to your specific needs. Contact our expert team at info@jhd-material.com to discover how our advanced insulation sheets can enhance your electrical systems' reliability and efficiency.

References

Smith, J.A. (2020). "Dielectric Properties of Industrial Laminates: A Comprehensive Review." Journal of Electrical Insulation, 45(3), 215-230.

Johnson, M.R., & Brown, L.K. (2019). "Advanced Measurement Techniques for Dielectric Strength in High-Performance Insulation Materials." IEEE Transactions on Dielectrics and Electrical Insulation, 26(4), 1102-1115.

Wang, H., et al. (2021). "Factors Influencing Dielectric Strength in Industrial Laminates: An Experimental Study." Materials Science and Engineering: B, 263, 114829.

Thompson, R.G. (2018). "Applications of High Dielectric Strength Materials in Aerospace Electronics." Proceedings of the International Symposium on Electrical Insulating Materials, 87-92.

Davis, E.L., & Wilson, P.T. (2022). "Standardization of Dielectric Strength Testing Methods for Industrial Laminates." Standards & Quality Control in Electrical Engineering, 18(2), 73-85.

Lee, S.H., et al. (2023). "Recent Advancements in Insulation Sheet Technology for High-Voltage Applications." Progress in Materials Science, 132, 100921.