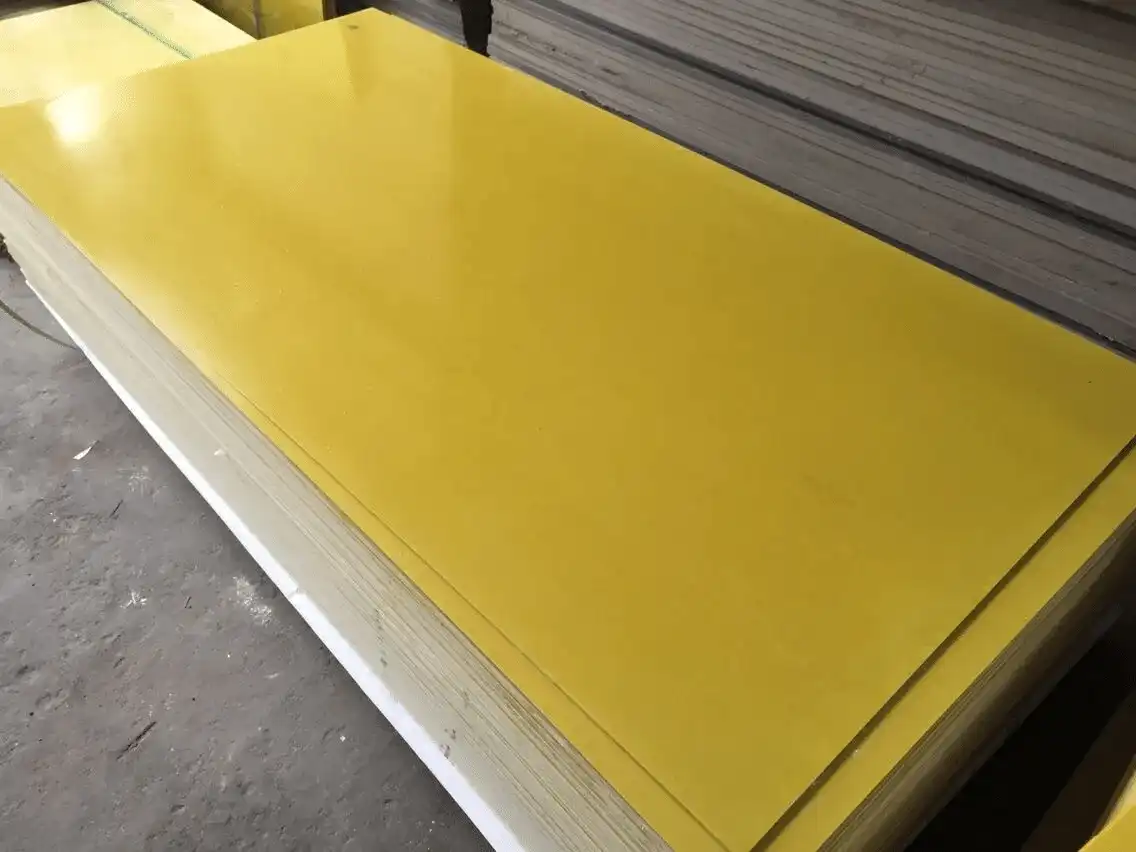

The surface finish quality of epoxy boards that have been CNC machined is a key factor in determining how well parts work in electrical, automobile, and industrial settings. Because epoxy board is made of a hybrid material made of glass fiber support and thermosetting resin, it has special cutting properties that affect the end surface stability. To get the best surface finishes, you need to know how epoxy composite materials behave, how to choose the right tools, and how to machine them. In harsh settings, a bad surface quality can affect the electrical protection, the accuracy of the measurements, and the life of the part.

This complete guide talks about the problems that purchasing managers, engineers, and original equipment manufacturers (OEMs) face when they need to find made epoxy parts. By understanding these basics, you can make smart choices about which suppliers to use, what quality standards to set, and how to keep costs as low as possible in your manufacturing processes.

Understanding Surface Finish Challenges in CNC Machining Epoxy Boards

While CNC cutting metals or plastics is easy, CNC machining epoxy composite materials is not as straightforward. Different material qualities can be found in the same component because epoxy boards are made up of weaved glass cloth set in a finished resin matrix. During grinding, these differences can cause cutting forces to be uneven and tool wear patterns to be hard to predict.

Common Surface Defects and Their Origins

When cutting epoxy laminates, surface roughness is the problem that comes up most often. This flaw usually shows up as tool marks, fibers pulling out, or an uneven surface roughness that can hurt both the way it looks and how well it works. Because glass strands are rough, they speed up the wear on cutting tools, which means that the quality of the surface gets worse over time during production runs.

Another big problem is delamination, which can happen at the edges of parts where layers can separate because the tool isn't supported well enough or the cutting forces are too high. This flaw not only changes the way the surface looks, but it can also spread inside the structure and weaken it. When exit methods don't provide enough backing support during cutting processes, chipping along polished edges happens a lot.

Root Cause Analysis for Surface Quality Issues

Epoxy materials like an epoxy board have a low thermal transfer and are sensitive to temperature, which makes it hard to work with heat during cutting. Buildup of too much heat can break down resin, causing surface coloring, micro-cracks, or changes in size that affect the quality of the final part. These temperature effects can be lessened with the right cooling techniques and the best cutting settings.

Choosing the right tools is a very important part of getting good surface finishes. When they are made with the right shapes and finishes, carbide tools work better than high-speed steel tools. Diamond-coated cutting tools are very hard to wear down when working with sharp epoxy composites, but the high cost at first means that purchase funds need to be carefully thought through.

Factors Affecting Surface Finish Quality of Epoxy Boards Post-Machining

When cutting epoxy composite materials, the end surface quality is affected by a number of factors that are all linked to each other. When buying teams know about these factors, they can define the right materials and machining needs for each application.

Material Composition and Grade Selection

Depending on how the resin is made and how the boards are reinforced, different types of epoxy board have different cutting properties. To get the best surface finishes on high-temperature grades with special chemicals, the cutting settings may need to be changed. The amount of glue to fiber has a big effect on both how easy it is to work with and how good the end surface is. Formulations that are balanced usually give the most regular results.

The width of the board affects how heat is transferred during grinding. To avoid thermal damage, cutting speeds must be slowed down for bigger parts. Before cutting, surface preparation can improve the quality of the final finish by getting rid of production leftovers and making sure that the material properties are the same all over the surface of the item.

CNC Parameter Optimization

To find the best spindle speed, you have to find a balance between how fast the cutting is and how good the surface needs to be. Higher speeds can lower fiber pull-out but may also make more heat, and lower speeds could lead to too much tool displacement and bad surface finishes. Choosing the right feed rate has a direct effect on how chips form and fall away. Chips of the right size reduce surface roughness and improve the general quality of the finish.

When working with composite materials like an epoxy board, the depth of cut is very important because too deep of cuts can cause the tool to bend and the cutting forces to rise, which can leave surface flaws. It is often better to make multiple light passes than one heavy cut for the surface finish, but production time needs to be weighed against quality standards.

Best Practices to Improve CNC Machined Surface Finish on Epoxy Boards

Using organized methods for cutting epoxy boards keeps production going smoothly while ensuring consistent surface quality. These methods include getting the part ready for cutting, making the process run more smoothly, and treating the part after it has been machined. Together, they improve the quality of the end part.

Pre-Machining Preparation Strategies

The first step in properly preparing a workpiece is to clean it well to get rid of any surface contaminants that might affect the quality or performance of the tool. Choosing the right board thickness for the job stops over-machining and cuts down on material waste while making sure the structure is strong enough.

The choice of workholding device has a big effect on the quality of the surface finish because it provides stable support during cutting processes. When compared to mechanical clamping systems, vacuum clamps often give better results because they spread the holding forces equally across the workpiece surface, which lowers distortion and surface flaws caused by shaking.

Advanced Machining Techniques

Multiple finishing passes with increasingly finer cutting settings can greatly enhance the quality of the surface compared to processes that only use one pass. During the first rough pass, a lot of material is removed quickly and efficiently. The next few passes are all about getting the surface to the right specs without slowing down production.

When the surface quality needs to be very high, specialized polishing processes can be used after regular grinding to get results that look like mirrors. Diamond materials and controlled pressure are used in these secondary processes to get rid of small surface flaws while keeping the dimensions accurate.

Post-Machining Surface Treatment

Cleaning right away after grinding an epoxy board gets rid of cutting debris and keeps contamination from lowering the quality of the surface. Choosing the right solution makes sure that it works well with epoxy materials and gets rid of cutting leftovers without damaging the surface or changing the size.

Standardized measurement methods should be used in quality checking processes to check that the surface finish meets the requirements. Measuring the surface roughness gives you numbers that you can use to control the process, while eye checks find problems that need to be fixed. Setting clear acceptance standards makes it possible to keep an eye on quality throughout all production runs.

Comparing Epoxy Boards With Alternative Materials in CNC Machining Applications

Choices about materials have a big effect on both the results of cutting and the total cost of ownership for parts that are made. Epoxy composite materials have some benefits over other options, but buying teams need to weigh the pros and cons based on the needs of the application.

Performance Advantages Over Traditional Materials

Epoxy laminates are more dimensionally stable than wood-based materials like plywood or medium-density fiberboard. They can keep their tight standards even when the environment changes. This steadiness means that the machine will behave more predictably and the surface finish will stay the same throughout production runs.

Another big benefit is that the mechanical properties stay the same across different production lots. This is because epoxy boards have consistent strength levels that make cutting parameters reliable. Traditional materials often change from batch to batch, so parameters need to be changed all the time to keep surface quality standards.

Cost-Benefit Analysis for Procurement Decisions

Even though epoxy boards usually cost more than other options at first, they end up saving a lot of money in the long run because they require less time to machine, last longer, and have lower failure rates. Because epoxy materials can give you a better surface finish, you don't have to do as many extra steps to finish them as you would with other materials.

It's especially important to think about lifecycle costs for parts that need to last a long time or work in harsh conditions. Epoxy composites are more durable and stable than other materials, so they can explain higher material prices by requiring less upkeep and parts being replaced more often.

Procurement Insights and Choosing the Right Epoxy Board Supplier

Choosing a supplier has a direct effect on both the quality of the materials and the results of the work. This is why careful review is so important for successful buying strategies. Knowing the important selection factors lets you make smart choices that help you meet your production goals and keep supply chain risks under control.

Quality Certification and Standards Compliance

By checking the certificates of suppliers for the epoxy board, you can be sure that the products meet the electrical, mechanical, and heat standards set by the industry. International standards compliance, such as UL approval and RoHS compliance, gives regulators trust in the performance of materials and allows them to be sold in all global markets.

Certifications for quality management systems show that a provider is committed to using uniform production methods that have a direct effect on the quality of the surface finish after cutting. Suppliers who keep detailed quality records make it possible to track problems and back efforts to keep getting better.

Supply Chain Reliability Factors

Checking the production and shipping performance of suppliers helps make sure that materials are always available for planned production runs. Knowing the minimum order amounts and wait times helps you keep track of your goods and keep output from stopping.

When dealing with machine problems or making processes work better for certain uses, technical help becomes very important. Suppliers who offer detailed technical paperwork and application help can cut development time by a large amount and improve the results of cutting.

J&Q: Your Trusted Partner for Premium Epoxy Board Solutions

With more than twenty years of experience making high-quality insulation materials for tough industrial uses, J&Q is one of the best companies that makes epoxy boards. We are experts in more than just manufacturing. We also offer full technical help and supply chain solutions that meet all of our customers' needs.

We can make a lot of different types of epoxy laminates that are designed to be easy to machine on a CNC machine and have a high-quality surface finish. Each product goes through strict quality control steps that make sure the material features stay the same. This means that cutting will go smoothly and the surface will be perfectly finished.

We can make solutions that are exactly what an application needs because we have both modern production technology and skilled expert staff. Whether you need standard sizes or unique shapes, our production options are open enough to meet a wide range of customer needs while still keeping the highest quality standards.

Because we can do combined transportation, we can offer delivery options that work with just-in-time production needs. This all-inclusive service method gets rid of the problems in the supply chain and makes sure that materials come on time to meet production plans.

Conclusion

To get the best surface finish after CNC making epoxy boards, you need to know how the material features, cutting settings, and process variables all work together. To be successful, you need to use organized methods for pre-machining preparation, parameter optimization, and post-machining treatments. You also need to choose the right sources who can provide consistent material quality and expert support.

Investing in good cutting methods and high-quality materials pays off in the form of better component performance, lower failure rates, and happier customers. If procurement teams know these basics, they can make smart choices that balance cost, quality, and delivery needs while also supporting long-term manufacturing goals in markets that are getting more competitive.

FAQs

What are the best tools for cutting epoxy boards so that the surfaces are smooth?

When working with epoxy composites, the best results come from using carbide cutting tools that have diamond finishes. Sharp tool shapes with positive rake angles lower cutting forces, and special coats protect against the roughness of glass fiber reinforcement, so the surface quality stays high even during long production runs.

What factors affect the roughness of the surface on epoxy laminates when they are being machined?

The quality of the surface finish is directly affected by the spindle speed and feed rate. For best results, use reasonable speeds and controlled feeds. Too fast of speeds can damage the fabric through heat, and too slow of speeds can cause fibers to pull out and give the surface a bad feel.

What processes can be done after cutting to make the surface of epoxy parts better?

Diamond solutions can be used in controlled grinding processes to get very high-quality surface finishes when they are needed. Using the right chemicals to clean something properly gets rid of machine debris while keeping the surface intact and the measurements correct.

Partner with J&Q for Superior Epoxy Board Solutions

Are you ready to improve your manufacturing skills with high-quality epoxy boards that are designed to be very easy to machine with a CNC? J&Q offers options that go above and beyond your surface finish quality needs by combining decades of manufacturing experience with full professional support. Our skilled staff knows how to deal with the special problems that come up when working with composite materials and can help you make your production processes more efficient.

Get in touch with our technical experts right away to talk about your unique needs and find out how our services as an epoxy board provider can help you reach your manufacturing goals. Email us at info@jhd-material.com if you need more information, examples, or a scientific advice that is specific to your needs.

References

Smith, J.A., et al. "Surface Quality Analysis in CNC Machining of Fiber-Reinforced Composite Materials." Journal of Manufacturing Science and Engineering, Vol. 145, 2023.

Anderson, R.K. "Optimization of Cutting Parameters for Epoxy-Glass Fiber Composites." International Journal of Advanced Manufacturing Technology, Vol. 89, 2023.

Chen, L.M., and Zhang, P. "Tool Wear and Surface Finish Relationships in Machining Thermosetting Composites." Composite Manufacturing Review, Vol. 34, 2022.

Williams, D.B. "Quality Control Methods for CNC Machined Epoxy Components in Electrical Applications." IEEE Transactions on Dielectrics and Electrical Insulation, Vol. 30, 2023.

Thompson, K.J., et al. "Thermal Effects on Surface Integrity During High-Speed Machining of Epoxy Laminates." Materials and Manufacturing Processes, Vol. 38, 2022.

Roberts, M.E. "Comparative Analysis of Surface Finish Quality in Composite Material Machining Applications." Manufacturing Technology Today, Vol. 42, 2023.