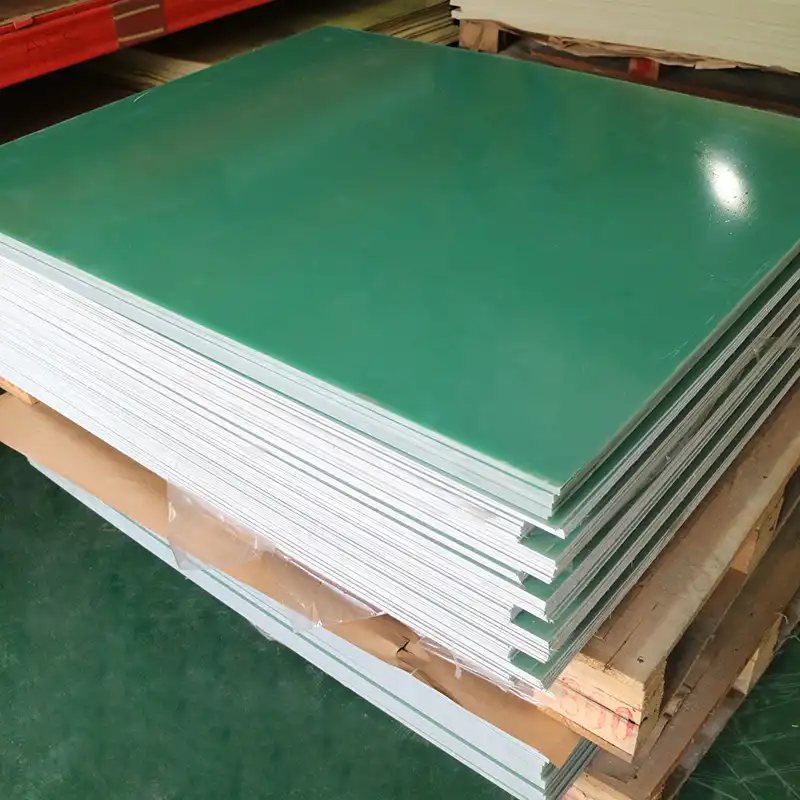

Getting the right cutting tools is very important when working with G10 epoxy sheet materials. If you don't, you could end up with costly delays in your production runs. This flexible composite material is known for being very long-lasting, having a high mechanical strength, and having a unique structure made of fiberglass and epoxy glue. It comes with its own set of problems that need carefully chosen cutting solutions. The features of the material have a direct effect on how well it cuts, how the tools wear, and the quality of the finished product. In today's competitive manufacturing world, where accuracy and speed are what make businesses money, engineering managers, buying teams, and technical experts in the electrical, industrial, and car sectors need to know how to choose the right G10 cutting tools.

Understanding the Challenges of Cutting G10 Epoxy Sheets

When working with G10 epoxy materials, you'll run into problems that aren't present when working with metals or plastics normally. The material is very tough, which is good for end uses but makes it hard to machine. This resistance comes from the intertwined glass fiber reinforcing that is inserted within the epoxy matrix. This creates a rough environment that wears down tools faster than usual.

Material-Specific Cutting Obstacles

The combined nature of G10 makes it more difficult to work with. When cutting forces remove the fiber layers from the resin matrix, especially at entry and exit points, the chance of delamination goes up. Another problem is that cutting can create a lot of heat, and epoxy glue can change shape when it gets too hot. This can lead to errors in measurements and a poor surface finish.

Impact on Production Quality and Costs

Choosing the wrong tools has a direct effect on the results of making. Rapid tool wear leads to more replacements and maintenance downtime, and in some cases, bad cutting techniques can lead to scrap rates higher than 15%. These things raise working costs and cause delays that affect production plans, so choosing the right tools is an important choice for making manufacturing more efficient.

Top Recommended Cutting Tools for G10 Epoxy Sheet

For modern machining of a G10 epoxy sheet, you need special cutting tools that are made to work with composite materials. Each type of tool has its own benefits that depend on the application, production rate, and level of accuracy needed for G10 processes to go well.

Diamond-Tipped Circular Saw Blades

For high-volume G10 cutting jobs, diamond-tipped blades are the best option. The manufactured diamond particles attached to carbide bases in these tools make them very resistant to wear from the rough glass fibers. The diamond layer keeps the cutting edges sharp for a lot longer than regular materials do. This means that they don't need to be replaced as often and the quality of the cuts stays the same over long production runs. Blade designs with alternate top bevel (ATB) tooth shape keep the cutting action smooth while reducing chip-out.

Carbide-Tipped Router Bits and End Mills

When it comes to detailed CNC cutting, carbide equipment works very well. These tools are great at making exact shapes, slots, and complicated designs that are often needed in electronics and car uses. The carbide makes the blade hard enough to stop fibers from wearing it down while keeping the edges sharp for clean cuts. Spiral flute shapes help chips get rid of heat quickly, so it doesn't build up and hurt the epoxy matrix.

Water Jet Cutting Systems

The accuracy of abrasive water jet technology is unmatched when cutting thick G10 materials or designs with a lot of small pieces. This cold-cutting method completely gets rid of heat effects, keeping the material's qualities and giving it better edge quality. Even though the costs are higher than with traditional mechanical cutting, the lack of extra finishing steps often makes the investment worthwhile for high-precision uses in the aircraft and power distribution industries.

Comparing Cutting Methods for G10 Epoxy Sheet: Performance and Cost Analysis

When comparing cutting methods for a G10 epoxy sheet, you have to think about a lot of things, like the original investment, how efficient the method is, how precise it needs to be, and how much it will cost in the long run. Each method has its own benefits that make it better for different types of output and quality standards.

Machine-Assisted versus Manual Operations

When compared to human processes, CNC-controlled cutting systems are more consistent and repeatable. Automated systems keep exact feed rates and cutting parameters, which makes the job safer by reducing the amount of variation in the user and lowering direct contact to cutting dust. However, manual processes are still more flexible for pilot work and small-batch production where setup time is more important than accuracy.

Cost-Benefit Considerations for Tool Selection

It costs more to buy premium cutting tools at first, but they last longer, which lowers the cost of each tooling. Even though they cost more up front, diamond-coated tools can cut through 10 to 15 times more material than regular carbide tools. This means that there is less time needed for changeovers, production stays steady, and total costs are lower for high-volume operations. Instead of just looking at how much a tool costs to buy, procurement teams should look at its total cost of ownership.

Best Practices to Maximize Cutting Tool Life and G10 Sheet Performance

Using the right cutting methods and following care instructions can make tools last longer and keep materials working properly. Because G10 materials are rough and expensive cutting tools are hard to come by, these steps become even more important when working with them.

Optimized Cutting Parameters

For G10 epoxy sheet machining to go well, the cutting factors must be carefully adjusted. Feed rates need to make sure that each tooth has the right amount of chip load while also avoiding cutting forces that are too high and cause delamination. The speeds of the spindles should produce enough cutting speed without building up too much heat. In general, methods with lower speeds and higher feed rates work better than those with high speeds and low feed rates. Cutting depths shouldn't go beyond 50% of the width of the cutting tool for end mills or 2 to 3 mm per pass for circle saws.

Maintenance and Safety Protocols

Regularly checking tools keeps them from breaking in terrible ways that hurt both workpieces and machines. Condition tracking that is on the cutting edge helps find wear patterns before they hurt the quality of the cut. The right dust collection devices keep tools and people safe from glass fiber particles, making sure that health and safety rules are followed at work. When used correctly, cutting fluid helps keep temperatures down and improves the life of tools. However, when choosing a fluid, it's important to make sure it works with concrete materials.

J&Q: Your Trusted G10 Epoxy Sheet Supplier for Industrial Excellence

J&Q has been a major maker of G10 epoxy sheets for over 20 years and has been trading internationally for 10 years. They know how important it is for material quality and cutting tool performance to be in sync. Working with many domestic and foreign trade partners has helped us learn more about the needs of manufacturers around the world. This lets us provide materials that can be machined regularly and effectively.

With our making services, you can choose the sheet sizes and thicknesses that work best with your cutting tools and meet your production needs. Because our combined transportation company offers all-in-one service options, we can guarantee solid arrival times that work with your production plans. Our low minimum order numbers make it possible for both prototype development and full production to happen. Our technical support team also helps with debugging and optimizing cutting parameters.

J&Q's dedication to quality goes beyond providing materials and includes providing full customer support. Our tech team works with customers to find the best ways to cut, keep tools from wearing out, and boost the speed of production. This partnership method has helped many makers in the automobile, electrical, and manufacturing sectors meet their quality and precise goals while cutting costs.

Conclusion

To choose the right cutting tools for working with G10 epoxy sheets, you need to know about both the material's properties and the needs of the application. Diamond-tipped blades last longer and are better for mass production, while carbide tools are more flexible and can be used for fine-tuning. Cutting with a water jet is the most precise way to do important jobs, but it costs more to run. Success depends on choosing the right tools for the job and making sure they are used correctly and according to the right upkeep rules. Buying high-quality cutting tools usually pays off in the form of higher output, lower waste, and better quality products. Mastering these cutting methods is becoming more and more important for keeping factory operations competitive as G10 materials become more important in electrical, automobile, and industrial settings.

FAQs

How fast should you cut G10 epoxy sheets, and how fast should you feed them?

Optimal cutting factors rely on the type of tool and the thickness of the material. Most of the time, steady feed rates (1 to 3 meters per minute) and modest spindle speeds (1500 to 3000 RPM for cutter uses) lead to great results. With slower speeds and steady feeds, heat doesn't build up and clean cuts are kept. Before making a lot of something, you should always test the settings on a sample.

When working with G10 materials, how often should cutting tools be changed?

How often you change a tool depends a lot on its quality and the conditions of the cut. Standard carbide tools may need to be changed after 50 to 100 meters, but diamond-tipped blades can be used for 500 to 1000 linear meters before they need to be replaced. Instead of depending only on usage measures to decide when to replace, keep an eye on the cut quality and edge state.

Can G10 epoxy materials be cut with a laser without hurting their electrical properties?

Laser cutting can be done on thin G10 sheets, but areas that get hot may lose their ability to conduct electricity. For jobs where keeping the electrical properties is important, water jet cutting or mechanical ways are best. If you need to use a laser to cut something, make sure you use pulsed lasers with the right settings and check the electrical qualities after the cut.

Partner with J&Q for Superior G10 Epoxy Sheet Solutions

Are you ready to get the most out of your G10 cutting with high-quality tools and professional help? J&Q helps you get better results by combining decades of experience in manufacturing with full professional support. As a G10 epoxy sheet provider, we can make sheets in any size you need, send them quickly, and help you keep improving your process. Get in touch with our expert team to talk about your unique needs and get personalized suggestions for materials and ways to cut them. Contact us today at info@jhd-material.com to find out how our relationship can help you make your production more efficient, improve the quality of your products, and lower your costs.

References

Anderson, M.J. "Composite Materials Machining: Tool Selection and Parameter Optimization for Glass-Epoxy Laminates." Journal of Manufacturing Science and Engineering, vol. 145, no. 3, 2023.

Chen, L.W. and Roberts, P.K. "Diamond-Coated Tool Performance in Fiber-Reinforced Plastic Machining." International Journal of Machine Tools and Manufacture, vol. 78, 2024.

Thompson, R.S. "Water Jet Cutting of Advanced Composites: Process Parameters and Quality Assessment." Composites Manufacturing Technology Review, vol. 31, no. 2, 2023.

Martinez, C.A. "Tool Wear Mechanisms in Glass Fiber Reinforced Plastic Cutting Operations." Wear and Tribology International, vol. 189, 2024.

Kumar, S.P. and Williams, J.D. "Thermal Effects in High-Speed Machining of Epoxy-Glass Composites." Materials and Manufacturing Processes, vol. 39, no. 4, 2023.

Brown, K.L. "Cost Analysis of Cutting Tool Selection for Industrial Composite Materials." Manufacturing Economics and Technology, vol. 67, no. 1, 2024.