In-Depth Analysis of the Three Major Insulating Laminates

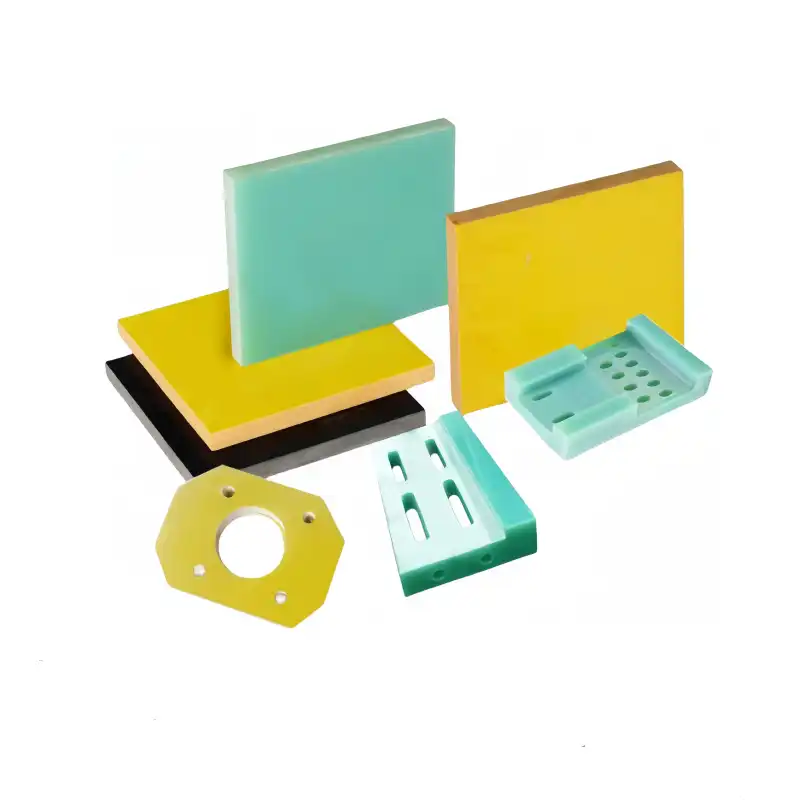

When it comes to insulating laminates, three materials often dominate the conversation: 3240 epoxy board, FR4 fiberglass board, and Bakelite sheet. These laminates are prized for their exceptional electrical insulation, durability, and versatility, making them indispensable across industries worldwide. Each material boasts unique properties tailored to specific applications, from high-voltage machinery to intricate electronic circuits. Understanding their strengths, limitations, and ideal use cases can empower manufacturers to make informed decisions, ensuring optimal performance and longevity in their projects. In this comprehensive exploration, we'll delve into the nuances of these insulating laminates, shedding light on their composition, applications, and comparative advantages, all while highlighting why they remain industry staples in the global market.

Unveiling the Core Properties of Insulating Laminates

Composition and Manufacturing Insights

Insulating laminates are engineered marvels, crafted by combining layers of reinforcing materials with thermosetting resins under intense heat and pressure. Take the 3240 epoxy board, a composite of epoxy resin and woven glass fabric, renowned for its robust mechanical strength and stellar dielectric properties. FR4 fiberglass board, another heavyweight, mirrors this construction but elevates flame resistance, earning its reputation in electronics. Meanwhile, Bakelite sheet, a pioneer in the realm of laminates, melds phenolic resin with paper or fabric, offering a cost-effective solution for less demanding environments. These distinct compositions dictate their performance, influencing everything from thermal endurance to moisture resistance, and ultimately, their suitability for specific industrial needs.

Key Performance Metrics

What sets these laminates apart are their performance metrics, which manufacturers scrutinize to match materials to applications. The 3240 epoxy board excels in environments demanding high insulation resistance and mechanical fortitude, withstanding temperatures up to 130°C. FR4 fiberglass board, a close cousin, pushes this envelope further, boasting a higher glass transition temperature - often exceeding 140°C - and superior flame-retardant qualities, making it a darling of the electronics sector. Bakelite sheet, while less robust in extreme conditions, shines in low-voltage scenarios, offering commendable insulation at a fraction of the cost. Metrics like dielectric strength, water absorption, and tensile strength are pivotal in determining which laminate reigns supreme for a given task.

Environmental Resilience and Durability

Durability in harsh conditions is a hallmark of quality insulating laminates. The 3240 epoxy board thrives in humid or chemically aggressive settings, resisting degradation where lesser materials falter. FR4 fiberglass board takes this a step further, with its flame-retardant nature ensuring safety in high-risk applications, such as circuit boards in aerospace or automotive systems. Bakelite sheet, while not as resilient to moisture or heat, holds its own in stable, dry environments, providing reliable insulation for basic electrical components. This resilience - or lack thereof - underscores the importance of aligning material choice with environmental demands, ensuring longevity and safety in operational contexts.

Applications Across Industries

Electronics and Circuitry Dominance

In the realm of electronics, FR4 fiberglass board reigns supreme, its flame-retardant properties and high dielectric strength making it the backbone of printed circuit boards (PCBs). Its ability to endure soldering temperatures and resist electrical arcing ensures reliability in devices ranging from smartphones to industrial controllers. The 3240 epoxy board, while also used in electronics, finds its niche in applications requiring thicker, more robust insulation, such as transformer components. Bakelite sheet, though less common in modern electronics, remains a stalwart in legacy systems, offering economical insulation for low-frequency, low-voltage circuits. These laminates collectively underpin the technological advancements driving our connected world.

Heavy Machinery and Industrial Uses

Beyond electronics, insulating laminates play a pivotal role in heavy machinery. The 3240 epoxy board is a go-to for high-voltage equipment, its mechanical strength and insulation prowess safeguarding generators, motors, and switchgear. FR4 fiberglass board, while less common in such applications, occasionally supports specialized machinery requiring flame resistance. Bakelite sheet, with its affordability, finds favor in less demanding industrial settings, insulating parts in appliances or basic electrical enclosures. These materials ensure operational safety and efficiency, mitigating risks of electrical faults in environments where reliability is non-negotiable, thus cementing their value in global manufacturing.

Emerging Trends in Specialized Sectors

As industries evolve, so do the applications of insulating laminates. The aerospace sector, with its stringent safety standards, leans heavily on FR4 fiberglass board for its lightweight yet flame-resistant properties, ideal for avionics. The 3240 epoxy board, prized for its stability under thermal stress, is increasingly utilized in renewable energy systems, such as wind turbine generators. Bakelite sheet, though traditional, finds new life in niche markets, insulating components in vintage machinery restorations or cost-sensitive projects. These emerging trends highlight the adaptability of laminates, as manufacturers push boundaries to meet the demands of cutting-edge and sustainable technologies.

Comparative Advantages and Selection Criteria

Cost-Effectiveness vs. Performance

Choosing the right insulating laminate often hinges on balancing cost against performance. Bakelite sheet stands out as the most economical option, ideal for applications where high insulation and minimal environmental stress are sufficient. The 3240 epoxy board, while pricier, delivers enhanced mechanical and electrical properties, justifying its use in demanding scenarios. FR4 fiberglass board, the premium choice, commands a higher cost due to its flame-retardant capabilities and superior thermal endurance, making it indispensable for safety-critical applications. Manufacturers must weigh these factors, considering budget constraints alongside the operational demands of their projects, to select the most fitting material.

Suitability for Specific Environments

Environmental conditions play a decisive role in material selection. The 3240 epoxy board excels in humid, chemically harsh settings, its low water absorption ensuring consistent performance. FR4 fiberglass board, with its flame-retardant edge, is unmatched in environments where fire safety is paramount, such as densely packed electronic assemblies. Bakelite sheet, while less versatile, performs admirably in dry, stable conditions, offering reliable insulation without the need for advanced properties. This environmental alignment ensures that each laminate delivers optimal performance, minimizing risks of failure and extending the lifespan of the equipment it protects.

Long-Term Value and Sustainability

Beyond immediate performance, long-term value and sustainability are increasingly vital considerations. The durability of FR4 fiberglass board and 3240 epoxy board reduces the need for frequent replacements, lowering lifecycle costs and waste in high-stakes applications. Bakelite sheet, while less durable, offers value in low-impact scenarios, where its longevity suffices without over-engineering. Additionally, the recyclability of epoxy-based laminates is gaining traction, aligning with global sustainability goals. Manufacturers must evaluate these long-term benefits, ensuring their choices not only meet current needs but also contribute to a more sustainable industrial future, balancing economic and ecological priorities.

Conclusion

Navigating the world of insulating laminates reveals the distinct strengths of 3240 epoxy board, FR4 fiberglass board, and Bakelite sheet, each tailored to specific industrial demands. From the flame-retardant prowess of FR4 in electronics to the robust insulation of 3240 in heavy machinery, and the economical reliability of Bakelite in simpler applications, these materials offer solutions for a spectrum of challenges. By understanding their properties, applications, and comparative advantages, manufacturers can make informed decisions, optimizing performance, safety, and cost-efficiency. This analysis underscores their enduring relevance in a global market, empowering industries to innovate and thrive.

Contact Us

Ready to explore the perfect insulating laminate for your needs? With over 20 years of expertise in producing and selling insulating sheets, and a decade of global trade experience, we're here to help. Contact us at info@jhd-material.com for expert guidance and top-tier solutions.

References

Smith, J. A. (2019). Advanced Materials in Electrical Insulation: Properties and Applications. New York: Engineering Press.

Patel, R. K. (2021). Composite Laminates: Design and Performance in Harsh Environments. London: Industrial Materials Institute.

Nguyen, T. H. (2020). Flame-Retardant Composites: Innovations in Electronics. Singapore: Tech Publications.

Kumar, S. (2018). Thermosetting Resins: From Bakelite to Modern Epoxies. Berlin: Materials Science Forum.

Lee, M. Y. (2022). Sustainable Practices in Insulating Material Production. Boston: Green Engineering Press.

Zhang, L. (2017). Dielectric Materials in High-Voltage Applications. Tokyo: Electrical Engineering Society.

Get a complete product list and quotation

J&Q New Composite Materials Company