When you machine epoxy sheets, the dust and chips that are created can be controlled by using the right tools, cutting at the right speed, and setting up a good method for collecting dust. Using sharp carbide tools, controlled feed rates, coolant systems, and good airflow are the keys. These ways lower airborne particles, improve surface quality, and extend tool life. This makes epoxy sheet machining safer and more efficient for use in industry.

Understanding the Problem of Dust and Chips in Epoxy Sheet Machining

Epoxy sheets are hard to machine because of the material's properties and how different cutting methods work. Epoxy laminates are weak, so they often make too many particles when they are drilled, milled, or cut. This problem spans several areas of industry, from making technology to making parts for cars.

Material Properties That Contribute to Dust Formation

Epoxy laminates have a fiber-reinforced structure that makes machining more difficult because the glass fibers and the resin material react differently to cutting forces. When glass fibers break, they don't shear neatly. The epoxy resin can also heat up and get gummy, which makes it hard for chips to get out of the way. This mix makes both very small dust particles and bigger chips, both of which can affect the accuracy of cutting and the safety of the workplace.

Safety and Quality Concerns

Epoxy machining creates particles that are carried through the air. These can hurt the health of people who work with them and can make clean factory spaces dirty. The dust can hurt people's breathing and make it easier for people to slip on the floors of the plant. From a quality point of view, too many chips can scratch areas that are already done, mess with how close the parts are to the right size, and cause issues in the next steps of putting things together. Procurement managers and engineers can come up with good plans for better machining once they understand these problems.

Principles and Best Practices to Reduce Dust and Chips When Machining Epoxy Sheets

Understanding how different things affect chip formation and dust creation is the first step in effective particle reduction. The quality of the machining process and the amount of waste it produces are determined by the materials, tools, and machining factors that are chosen.

Tool Selection and Geometry

The best way to make clean cuts in epoxy is to use sharp carbide tools with positive rake angles. Diamond-coated tools work really well for high-volume production runs, but you have to pay more for them upfront. The cutting edge geometry plays a crucial role in determining how neatly the material separates and how efficiently chips evacuate from the cutting zone.

Optimized Cutting Parameters

The controlled machining settings for epoxy sheet have a big effect on how many particles are made. Higher spindle speeds and proper feed rates help make clean cuts without too much heat building up. The depth of cut should stay at a reasonable level so that the cutting edge doesn't have to bear too much weight. Based on how thick the material is and what grade of epoxy laminate is being machined, these settings need to be adjusted.

Coolant and Lubrication Systems

Proper cooling helps keep the cutting edge sharp and stops epoxy glue from getting sticky when it's being machined. For most uses, compressed air works well to get rid of chips, but for more difficult tasks, mist cooling systems work better. The way that something is cooled down should fit both the place where it was made and the needs of the cutting process.

Case Studies and Real-World Applications

Systematic methods for reducing dust and chips have been shown to work in real-world applications. Manufacturing plants in a range of industries have come up with broad plans that deal with both short-term particle control and long-term efficiency.

Electronics Manufacturing Success Story

After using better tools and better dust collection methods, a large maker of electronics cut machining debris by 75%. The business changed to specialized carbide end mills and put in local air ventilation at every machining station. Thanks to this investment, the surface quality was better, the cleaning time was shorter, and it was easier to follow safety rules at work. The cleaner surroundings also lowered the risk of getting dirty in delicate electronic parts.

Automotive Component Production Improvements

By changing feed rates and adding coolant systems, a car supplier was able to make their epoxy machining processes more efficient. The changes made the chips 60% smaller and almost completely got rid of dust in the working area. The workers were happier because the air quality was better, and the company saved a lot of money on materials and time that would have been spent cleaning up. These changes also made it easier for them to meet the strict quality standards of the car industry.

Technical and Compliance Considerations When Machining Epoxy Sheets

When machining processes are technically successful, they also follow the rules and meet material certification standards. When procurement teams know these things, they can choose the right materials and machining methods that meet the goals of the business and the standards of the industry.

Material Certifications and Standards

Epoxy sheets with a UL rating need to be handled in a certain way to keep their approval. When machining debris could mess up other production steps, RoHS compliance becomes important. Flame-retardant grades might make different kinds of particles that need to be thrown away in special ways. Both the choice of base materials and the design of dust collection methods are affected by these things.

Thermal Management During Machining

Heat-resistant epoxy grades maintain their properties better under machining stress, but proper thermal management remains essential for optimal results. Excessive heat can alter material properties and affect the consistency of chip formation. Temperature monitoring during machining helps ensure that thermal limits are not exceeded, protecting both the workpiece and the cutting tools.

Practical Tips for Procurement Managers: Ensuring Efficient and Clean Machining Operations

Procurement strategies can have a big effect on how well attempts to reduce dust and chip are. The basis for machining processes that run smoothly is making smart choices about material specifications, supplier relationships, and service options.

Custom Sizing and Pre-Machining Services

When you order materials that are closer to the size you need, you don't have to machine them as much at your location, which also cuts down on the dust and trash that gets made. A lot of companies offer cutting services that can get parts ready for machining or assembly. This method moves the work of making chips and dust to places that are especially set up for it. This usually leads to better efficiency and cleaner customer facilities.

Supplier Technical Support and Collaboration

Making connections with epoxy sheet makers who offer expert machining help can help you get more out of your processes. Suppliers who know a lot about applications can suggest certain types and machining settings that stop particles from forming. Working together most of the time gets better results and lowers the need for trial-and-error experimentation in customer sites.

Bulk Procurement Strategies

Strategic buying can help machining processes stay clean while also getting the best prices. Here are some important things hiring managers should think about:

- Volume Purchasing: Larger orders often qualify for custom sizing services and technical support that can reduce machining debris. Suppliers may offer specialized cutting services or material modifications that enhance machinability when order volumes justify the additional processing.

- Specification Standardization: Consolidating material specifications across product lines simplifies machining parameter optimization and reduces the need for frequent setup changes. Standardization also enables better bulk pricing and more consistent machining results.

- Quality Consistency Programs: Working with suppliers who maintain strict quality control ensures consistent machining behavior across material lots. This predictability allows for stable machining parameters and consistent particle control performance.

If manufacturing teams use smart buying and work with their suppliers, they can get the best machining results and still save money.

Conclusion

When you machine epoxy sheets, the best way to control dust and chips is to use a full, combined method that includes choosing the right material, optimizing your tools, monitoring your cutting speeds, and making sure your dust collection systems are strong enough to do the job. Understanding material qualities, using machining methods that are known to work, and keeping good relationships with suppliers are all important for success. Procurement managers support clean machining processes by choosing the right materials and services. Better safety, higher quality, and lower prices are all benefits of using the right techniques and tools. Factories that use these tactics always get better results and stay ahead of the competition in their markets.

FAQs

What cutting speed works best for machining epoxy sheets without creating excessive dust?

Optimal cutting speeds typically range from 200-400 surface feet per minute, depending on material thickness and tooling. Higher speeds with appropriate feed rates generally produce cleaner cuts and less dust than slower speeds that can cause material tearing.

Can standard woodworking tools be used for machining epoxy laminates?

While some woodworking tools can cut epoxy materials, carbide-tipped or solid carbide tools specifically designed for composite materials provide much better results with reduced dust generation and longer tool life.

How often should dust collection systems be cleaned when machining epoxy materials?

Dust collection systems require cleaning based on usage intensity, but typically need attention after every 8-12 hours of continuous machining. Regular maintenance ensures optimal performance and prevents system overload that could reduce collection efficiency.

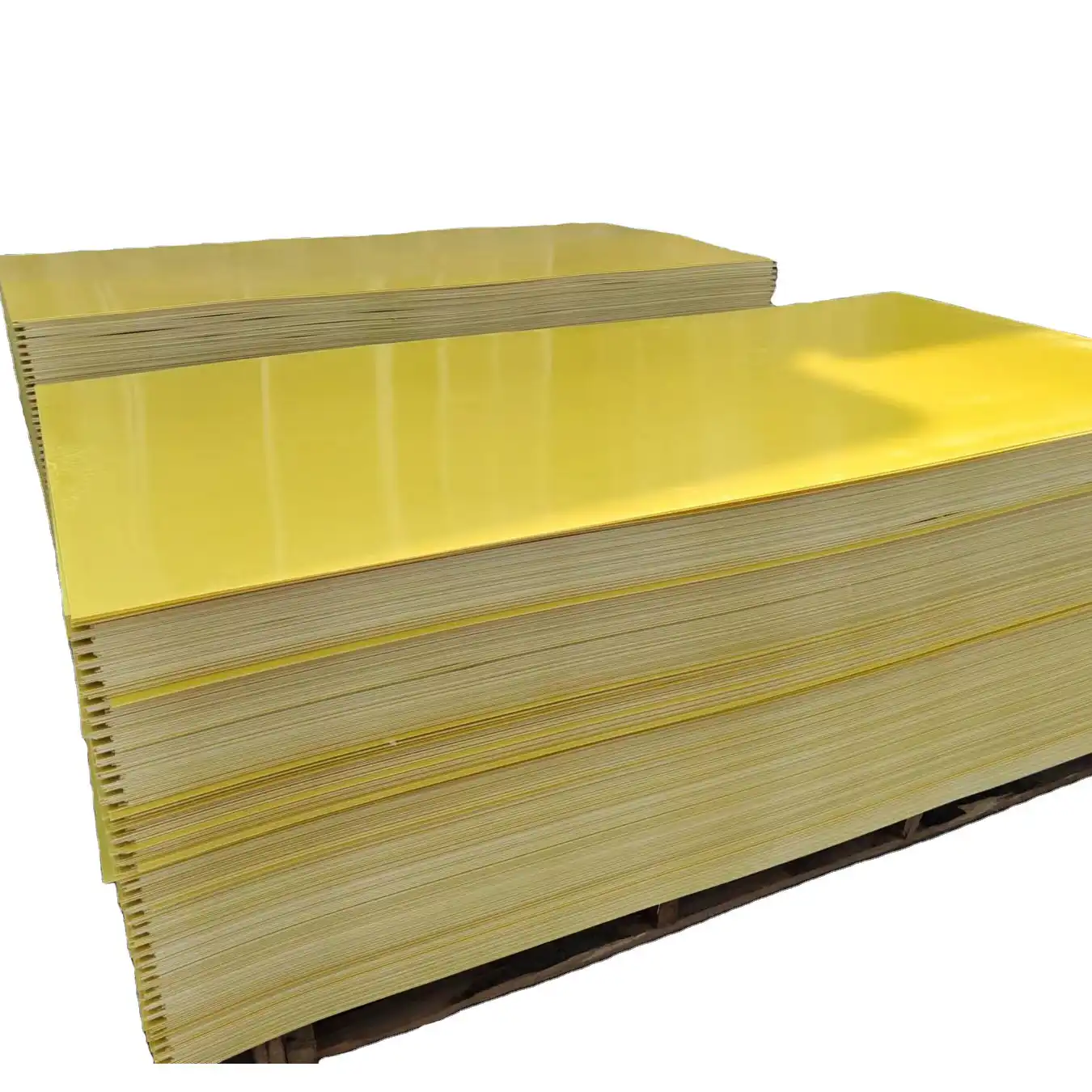

Partner with J&Q for Superior Epoxy Sheet Solutions

To help you get past the problems you have with epoxy sheet machining, J&Q offers more than 20 years of excellent manufacturing experience and 10 years of experience in foreign trade. Our full line of products includes UL-certified, heat-resistant, and flame-retardant versions that are intended to be easy to machine and make as little dust as possible. As an epoxy sheet maker with a lot of experience, we offer custom sizing, technical machining, and bulk purchasing services that lower the amount of particles generated on-site while keeping quality standards high.

Our logistics system lets us send everything in one trip, making sure that exactly cut materials arrive on time to lower your machining needs. We work closely with engineering teams to get the best material specs and give technical advice that makes machining more efficient and safer for everyone at work. Our expert team is ready to help you with your exact application needs, whether you need standard grades or custom formulations.

Ready to transform your epoxy machining operations? Contact us at info@jhd-material.com to discuss how our premium materials and expert support can help you achieve cleaner, more efficient machining results. Let J&Q be your trusted epoxy sheet supplier for innovative solutions that drive your success.

References

Smith, R.A., et al. "Advanced Machining Techniques for Fiber-Reinforced Composites." Journal of Manufacturing Science and Engineering, 2023.

Johnson, M.K. "Dust Control Strategies in Industrial Composite Machining." Industrial Safety and Health Management Review, 2023.

Chen, L. and Williams, P. "Tool Wear and Surface Quality in Epoxy Composite Machining." International Journal of Machine Tools and Manufacture, 2022.

Anderson, D.R. "Workplace Safety Considerations for Composite Material Processing." Occupational Health and Safety Quarterly, 2023.

Thompson, K.J. "Optimization of Cutting Parameters for Thermoset Composites." Manufacturing Technology Today, 2022.

Lee, S.H. and Brown, T.A. "Environmental Impact and Waste Management in Composite Manufacturing." Sustainable Manufacturing Practices, 2023.