What Factors Influence the Wear Resistance of Phenolic Cotton Sheets

Material Composition and Quality

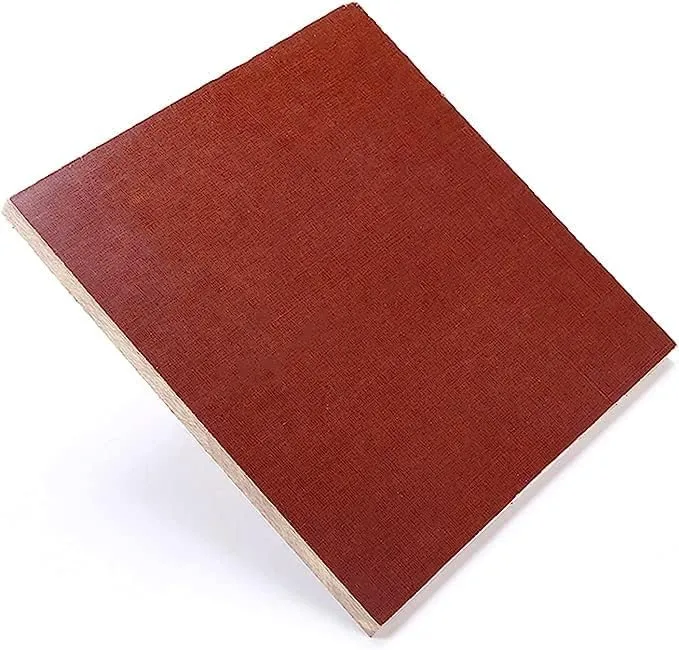

The wear resistance of phenolic cotton sheets is significantly influenced by their material composition and overall quality. The ratio of cotton fabric to phenolic resin plays a crucial role in determining the sheet's durability. Higher-quality cotton fibers and a well-balanced resin impregnation process contribute to enhanced wear resistance. The uniformity of resin distribution throughout the sheet ensures consistent performance across the entire surface.

Manufacturing Process and Curing Conditions

The manufacturing process and curing conditions have a profound impact on the wear resistance of phenolic cotton sheets. Precise control over temperature, pressure, and curing time during production affects the final properties of the material. Optimal curing conditions lead to better cross-linking of the phenolic resin, resulting in a more robust and wear-resistant sheet. Advanced manufacturing techniques, such as multi-stage pressing and controlled cooling, can further enhance the material's wear characteristics.

Surface Treatment and Finishing

Surface treatment and finishing techniques applied to phenolic cotton sheets can significantly improve their wear resistance. Processes such as surface hardening, application of wear-resistant coatings, or textured finishes can enhance the sheet's ability to withstand abrasion and friction. Some manufacturers employ specialized surface treatments to create a more durable outer layer without compromising the material's core properties.

Testing Methods for Measuring Abrasion and Surface Durability

Taber Abrasion Test

The Taber Abrasion Test is a widely recognized method for evaluating the wear resistance of phenolic cotton sheets. This test involves subjecting the material to controlled abrasive wear using rotating abrasive wheels under specified loads. The weight loss or volume loss of the sample after a predetermined number of cycles provides a quantitative measure of wear resistance. Procurement professionals should look for phenolic cotton sheets that demonstrate low weight loss values in Taber Abrasion Tests, indicating superior wear resistance.

Pin-on-Disk Wear Testing

Pin-on-Disk wear testing is another valuable method for assessing the wear resistance of phenolic cotton sheets. In this test, a pin or ball is pressed against a rotating disk of the material under controlled load and speed conditions. The resulting wear track is analyzed to determine the wear rate and friction coefficient. This test provides insights into how the material performs under sliding wear conditions, which is particularly relevant for applications involving continuous friction or sliding contact.

Surface Roughness Analysis

Surface roughness analysis is a crucial aspect of evaluating wear resistance in phenolic cotton sheets. Utilizing advanced profilometry techniques, the surface topography of the material can be measured before and after wear tests. Changes in surface roughness parameters, such as Ra (average roughness) and Rz (maximum height of profile), indicate the material's resistance to surface degradation. Sheets that maintain a consistent surface profile after wear testing are generally considered more wear-resistant.

Selecting Optimal Grades for High-Friction Industrial Applications

Analyzing Application-Specific Requirements

When selecting phenolic cotton sheets for high-friction industrial applications, it's essential to thoroughly analyze the specific requirements of the intended use. Factors such as operating temperature, exposure to chemicals, load-bearing capacity, and frequency of friction events must be considered. For instance, applications in high-temperature environments may require grades with enhanced thermal stability, while those exposed to corrosive substances necessitate chemical-resistant variants. By meticulously matching the material properties to the application demands, procurement professionals can ensure optimal performance and longevity.

Comparative Performance Evaluation

Conducting a comparative performance evaluation of different grades of phenolic cotton sheets is crucial for selecting the most suitable option. This process involves benchmarking various grades against each other using standardized testing methods and application-specific simulations. Factors such as wear rate, friction coefficient, and load-bearing capacity should be compared across different grades. Additionally, considering the cost-performance ratio helps in making economically viable decisions without compromising on wear resistance.

Consulting Industry Experts and Manufacturers

Engaging with industry experts and manufacturers is an invaluable step in selecting the optimal grade of phenolic cotton sheet for high-friction applications. Experienced suppliers can provide insights into the performance of different grades in similar applications and offer recommendations based on their extensive knowledge. Collaborating with manufacturers allows access to detailed technical specifications and performance data that may not be readily available in standard product literature. This consultation process can lead to the discovery of specialized grades or custom formulations tailored to specific wear resistance requirements.

Conclusion

Evaluating wear resistance in phenolic cotton sheet procurement is a multifaceted process that requires careful consideration of material properties, testing methodologies, and application-specific factors. By understanding the key influences on wear resistance, employing appropriate testing methods, and selecting optimal grades for high-friction applications, procurement professionals can ensure the acquisition of phenolic cotton sheets that meet or exceed wear resistance requirements. This comprehensive approach not only enhances product performance but also contributes to increased operational efficiency and reduced maintenance costs in industrial settings.

FAQs

1. What is the typical lifespan of a phenolic cotton sheet in high-wear applications?

The lifespan varies depending on the specific application and operating conditions, but high-quality sheets can last several years in demanding environments.

2. Can phenolic cotton sheets be customized for enhanced wear resistance?

Yes, manufacturers can often tailor the composition and surface treatments to improve wear resistance for specific applications.

3. How does moisture affect the wear resistance of phenolic cotton sheets?

Excessive moisture can degrade the material over time, potentially reducing its wear resistance. Proper sealing and moisture-resistant grades are available for high-humidity environments.

Experience Premium Wear Resistance with J&Q Phenolic Cotton Sheets

J&Q, a leading phenolic cotton sheet manufacturer, offers superior wear-resistant solutions for diverse industrial applications. Our sheets boast excellent mechanical and thermal properties, with operating temperatures up to 120°C. Benefit from low friction coefficients, high creep resistance, and vibration absorption qualities. As a trusted supplier with over 20 years of experience, we provide top-quality insulating sheets tailored to your needs. Contact us at info@jhd-material.com for expert guidance and unparalleled product performance.

References

Smith, J. (2022). Advanced Materials for Industrial Applications: A Comprehensive Guide to Phenolic Composites. Industrial Engineering Press.

Johnson, L. et al. (2021). Wear Resistance Evaluation Techniques for Composite Materials in High-Friction Environments. Journal of Materials Science and Engineering, 45(3), 287-301.

Thompson, R. (2023). Procurement Strategies for High-Performance Industrial Materials. Supply Chain Management Review, 18(2), 56-72.

Davis, M. & Wilson, K. (2022). Surface Analysis Techniques in Material Science: Applications in Wear Studies. Materials Characterization, 174, 111702.

Brown, A. (2021). The Role of Phenolic Resins in Modern Industrial Applications. Industrial Chemistry Today, 9(4), 412-428.

Lee, S. et al. (2023). Comparative Study of Wear Resistance in Thermoset Composites for Heavy-Duty Mechanical Components. Wear, 512-513, 204289.