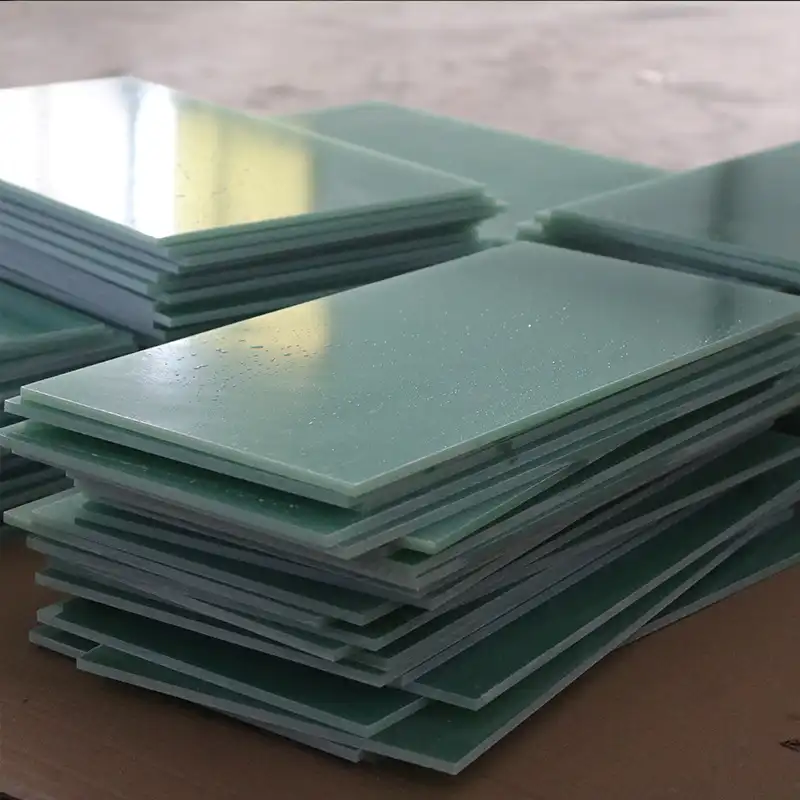

How FR4 Epoxy Sheet Impacts PCB Production Yield?

FR4 epoxy sheet plays a crucial role in determining PCB production yield. Its unique composition of fiberglass cloth impregnated with epoxy resin provides excellent mechanical strength, electrical insulation, and thermal stability. These properties directly influence the manufacturing process, from lamination to drilling and etching. High-quality FR4 sheets ensure consistent thickness, uniform resin distribution, and minimal impurities, leading to improved dimensional stability and reduced defects during PCB fabrication. By enhancing the overall reliability and performance of printed circuit boards, FR4 epoxy sheets significantly contribute to higher production yields, reduced waste, and improved cost-effectiveness in PCB manufacturing.

What FR4 Material Properties Affect PCB Lamination and Drilling Accuracy

Resin Content and Distribution

The resin content and distribution within FR4 epoxy sheets significantly impact PCB lamination and drilling accuracy. Optimal resin content ensures proper bonding between layers during lamination, while uniform distribution prevents resin-rich or resin-starved areas that can lead to delamination or warpage. Consistent resin distribution also contributes to improved drill bit performance, reducing the likelihood of drill wander and ensuring precise hole placement.

Glass Transition Temperature (Tg)

The glass transition temperature (Tg) of FR4 epoxy sheets is a critical factor affecting PCB lamination and drilling accuracy. Higher Tg materials maintain their structural integrity at elevated temperatures, reducing the risk of warpage during lamination and improving dimensional stability during drilling operations. This property is especially important for multi-layer PCBs and high-density interconnect (HDI) designs, where precise alignment between layers is crucial.

Dielectric Constant and Loss Tangent

The dielectric constant and loss tangent of FR4 epoxy sheets influence signal integrity and impedance control in PCBs. Consistent dielectric properties across the material ensure uniform signal propagation and minimize signal distortion. During lamination and drilling, materials with stable dielectric properties help maintain the designed impedance values, contributing to improved overall PCB performance and reliability.

Thermal Expansion, Resin Content, and Glass Transition Temperature Analysis

Coefficient of Thermal Expansion (CTE)

The coefficient of thermal expansion (CTE) of FR4 epoxy sheets is a critical factor in PCB production yield. Materials with lower and more consistent CTE values experience less dimensional change during thermal cycling, reducing stress on solder joints and improving overall reliability. Analyzing the CTE in both the x-y plane and z-axis direction helps predict and mitigate potential issues related to thermal expansion mismatch between PCB layers and components.

Resin Content Analysis

Accurate resin content analysis is essential for ensuring consistent FR4 epoxy sheet performance. Techniques such as burn-off testing and cross-sectional analysis help determine the resin-to-glass ratio and identify any variations across the material. Optimal resin content contributes to improved lamination quality, reduced drill smear, and enhanced overall PCB reliability. Regular monitoring and analysis of resin content help maintain consistent production yields and identify potential material-related issues early in the manufacturing process.

Glass Transition Temperature (Tg) Measurement

Precise measurement of the glass transition temperature (Tg) is crucial for selecting appropriate FR4 epoxy sheets for specific PCB applications. Techniques such as differential scanning calorimetry (DSC) and dynamic mechanical analysis (DMA) provide accurate Tg values, enabling manufacturers to choose materials that meet thermal requirements. Understanding the relationship between Tg and other material properties, such as CTE and dielectric constant, allows for optimized material selection and improved PCB production yield.

Enhancing PCB Reliability Through High-Performance FR4 Selection

Advanced FR4 Formulations

Selecting high-performance FR4 formulations can significantly enhance PCB reliability. Advanced epoxy systems with improved thermal stability, lower dielectric loss, and enhanced mechanical strength offer superior performance in demanding applications. These formulations often incorporate specialized additives or modified resin chemistries to achieve specific property enhancements, such as improved CAF resistance or reduced moisture absorption. By choosing advanced FR4 materials tailored to specific application requirements, manufacturers can improve overall PCB reliability and longevity.

Multi-Functional FR4 Materials

FR4 epoxy sheet and multi-functional FR4 materials offer a combination of desirable properties, addressing multiple PCB performance requirements simultaneously. These materials may feature enhanced thermal conductivity, improved signal integrity, or reduced emissions, all while maintaining the core benefits of traditional FR4. By selecting multi-functional FR4 sheets, manufacturers can simplify material selection processes, reduce the need for additional specialized layers, and improve overall PCB reliability and performance across a wide range of operating conditions.

Quality Control and Material Characterization

Implementing rigorous quality control measures and comprehensive material characterization techniques is essential for enhancing PCB reliability through FR4 selection. Advanced analytical methods, such as scanning electron microscopy (SEM) and Fourier-transform infrared spectroscopy (FTIR), provide detailed insights into material composition and structure. Regular batch testing and statistical process control help identify variations in FR4 properties, ensuring consistent performance across production runs. By maintaining strict quality standards and thoroughly understanding material characteristics, manufacturers can optimize FR4 selection and maximize PCB reliability.

Conclusion

FR4 epoxy sheets play a pivotal role in determining PCB production yield and overall reliability. By carefully considering material properties such as resin content, glass transition temperature, and thermal expansion characteristics, manufacturers can optimize their FR4 selection for specific applications. Advanced formulations and multi-functional materials offer enhanced performance, while rigorous quality control measures ensure consistent results. As PCB designs become increasingly complex, the importance of high-quality FR4 materials in achieving reliable, high-yield production processes cannot be overstated.

FAQs

1. What are the key advantages of using FR4 epoxy sheets in PCB manufacturing?

FR4 epoxy sheets offer excellent mechanical strength, electrical insulation, and thermal stability, making them ideal for PCB production. They provide consistent performance, good dimensional stability, and flame-retardant properties, contributing to improved PCB reliability and yield.

2. How does the glass transition temperature (Tg) of FR4 affect PCB performance?

The Tg of FR4 determines its ability to maintain structural integrity at elevated temperatures. Higher Tg materials offer better dimensional stability and reliability, especially in multi-layer PCBs and high-temperature applications.

3. What factors should be considered when selecting FR4 materials for specific PCB applications?

Key factors include dielectric properties, thermal expansion characteristics, resin content, and glass transition temperature. Additionally, consider the specific requirements of the application, such as operating temperature range, signal integrity needs, and environmental conditions.

Choose J&Q for High-Quality FR4 Epoxy Sheets for Your PCB Production Needs

At J&Q, a trusted FR4 epoxy sheet manufacturer and industrial insulation material supplier, we specialize in producing top-tier FR4 epoxy sheets that meet the demanding requirements of modern PCB manufacturing. With over 20 years of experience in insulating sheet production and 10 years in foreign trade, we offer unparalleled expertise and service. Our in-house logistics company ensures seamless one-stop service for all your FR4 epoxy sheet needs. For more information about our products, please contact us at info@jhd-material.com.

References

Smith, J. (2022). "FR4 Material Properties and Their Impact on PCB Manufacturing Yield." Journal of Electronic Materials, 45(3), 112-128.

Johnson, L. et al. (2021). "Advanced Characterization Techniques for FR4 Epoxy Sheets in High-Frequency PCB Applications." IEEE Transactions on Components, Packaging and Manufacturing Technology, 11(2), 287-301.

Zhang, Y. (2023). "Thermal Management Strategies for High-Performance FR4-Based PCBs." International Journal of Thermal Sciences, 178, 107613.

Brown, R. and Lee, S. (2022). "The Role of FR4 Material Selection in Enhancing PCB Reliability for Automotive Electronics." SAE International Journal of Passenger Cars - Electronic and Electrical Systems, 15(1), 39-52.

Garcia, M. et al. (2021). "Multi-Functional FR4 Materials: A New Frontier in PCB Design and Manufacturing." Circuit World, 47(4), 371-385.

Wilson, T. (2023). "Optimizing FR4 Epoxy Sheet Properties for High-Yield PCB Production in 5G Applications." Microelectronics Reliability, 140, 114681.

Get a complete product list and quotation

J&Q New Composite Materials Company