Understanding Phenolic Sheets and Their Properties

Composition and Manufacturing Process of Phenolic Sheets

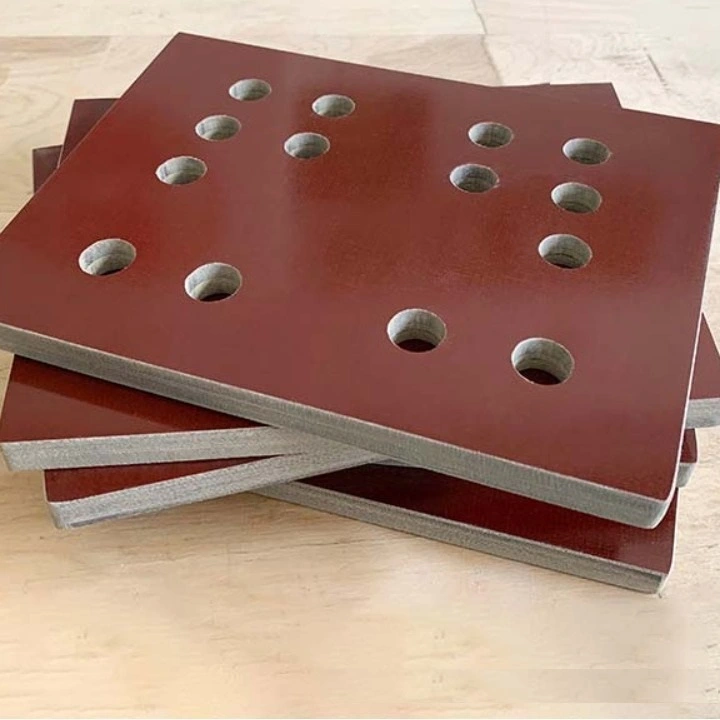

Phenolic sheets are engineered by layering paper, cotton, or glass fabric materials that have been thoroughly impregnated with phenolic resin. These layers are then subjected to intense heat and pressure during a controlled curing process, causing the resin to polymerize and form a solid, thermoset matrix. The result is a rigid, durable sheet with a uniform structure. This method ensures that the final product possesses enhanced mechanical strength, excellent electrical insulation, and heat resistance, making it suitable for a wide range of industrial applications.

Physical and Mechanical Properties of Phenolic Sheets

Phenolic sheets offer a combination of physical and mechanical strengths that make them highly functional in demanding applications. They are known for their high compressive and tensile strength, dimensional stability, and resistance to wear and deformation. The sheets also exhibit low moisture absorption and superior chemical resistance, allowing them to maintain performance even in harsh environments. Their low thermal conductivity further supports their use in insulating applications, and these properties collectively influence machining strategies and material selection.

Common Applications of Phenolic Sheets in Industry

Due to their robust performance characteristics, phenolic sheets are widely used across multiple industries. In the electrical sector, they serve as insulation barriers and components in switchgear and transformers. In automotive and aerospace industries, they are used for structural components and thermal barriers. Construction sectors employ them in high-strength, moisture-resistant materials. Phenolic sheets also support industrial machinery with their high durability and resistance to friction, making them ideal for bushings, washers, and wear-resistant mechanical parts.

Essential Tools and Equipment for Drilling and Milling Phenolic Sheets

Selecting the Right Drill Bits and Milling Cutters

Choosing the appropriate tools is paramount when working with phenolic sheets. High-speed steel (HSS) or carbide-tipped drill bits and milling cutters are recommended for their durability and heat resistance. For drilling, opt for brad point bits or specialized composite drill bits that minimize delamination. When milling, select end mills with multiple flutes to ensure smooth cuts and reduce the risk of chipping.

Importance of Tool Sharpness and Maintenance

Maintaining sharp tools is crucial for achieving clean cuts in phenolic sheets. Dull tools can cause excessive heat buildup, leading to material burning or cracking. Regularly inspect and sharpen your drill bits and milling cutters to ensure optimal performance. Consider using diamond-coated sharpening tools or professional sharpening services to maintain the precise cutting edges required for working with composite materials.

Recommended Machinery for Processing Phenolic Sheets

While phenolic sheets can be machined using standard woodworking equipment, specialized machinery can enhance precision and efficiency. CNC routers offer unparalleled accuracy and repeatability for complex cuts and shapes. Vertical milling machines with variable speed control allow for fine-tuning of cutting parameters. For large-scale production, consider investing in dedicated composite processing equipment designed to handle the unique challenges posed by phenolic sheets.

Best Practices for Drilling and Milling Phenolic Sheets

Proper Workpiece Support and Clamping Techniques

Adequate support and secure clamping are essential for achieving clean, crack-free cuts in phenolic sheets. Use a sacrificial backing board to prevent splintering and tear-out on the exit side of holes or cuts. Employ vacuum tables or mechanical clamps to hold the workpiece firmly in place, ensuring stability throughout the machining process. For curved or irregular shapes, consider using custom jigs or fixtures to maintain consistent support across the entire surface.

Optimizing Cutting Speed and Feed Rate

Finding the right balance between cutting speed and feed rate is crucial for successful phenolic sheet machining. Generally, slower spindle speeds and moderate feed rates yield the best results. Start with conservative settings and gradually increase until you achieve the desired cut quality. Monitor heat buildup and adjust parameters accordingly to prevent material degradation. For CNC operations, utilize climb milling techniques to reduce cutting forces and improve surface finish.

Cooling and Dust Extraction Strategies

Effective cooling and dust extraction are vital for both tool longevity and workplace safety when working with phenolic sheets. Implement a compressed air cooling system to dissipate heat at the cutting point, or use cutting fluids specifically formulated for composite materials. Install a robust dust extraction system to capture fine particles generated during machining, as phenolic dust can be harmful if inhaled. Consider using dust extraction attachments on handheld tools for smaller projects or when working in confined spaces.

Conclusion

Mastering the art of drilling and milling phenolic sheets without cracking requires a combination of proper technique, appropriate tools, and careful attention to detail. By understanding the unique properties of phenolic materials and implementing the best practices outlined in this guide, you can achieve superior results in your projects. Remember to prioritize safety, maintain your equipment, and continually refine your approach to working with these versatile composite sheets. With practice and patience, you'll be able to harness the full potential of phenolic sheets in your industrial applications.

Contact Us

Ready to elevate your phenolic sheet projects? For expert advice, high-quality materials, and comprehensive support, contact our team at info@jhd-material.com. Let's bring your ideas to life with precision and excellence!