How to CNC Machine Phenolic Cotton Sheets Without Chipping?

To CNC machining phenolic cotton sheets without breaking, you need to carefully choose the tools, set the cutting settings so they work best, and hold the workpiece correctly. It's important to use sharp carbide or diamond-coated tools with the right shape, keep the spinning speed between 8,000 and 12,000 RPM, and make sure there is enough cooling flow. With the right feed rates and short depth cuts, you can keep the material from being stressed, which is what usually breaks the edges of these composite layered materials during industrial manufacturing processes.

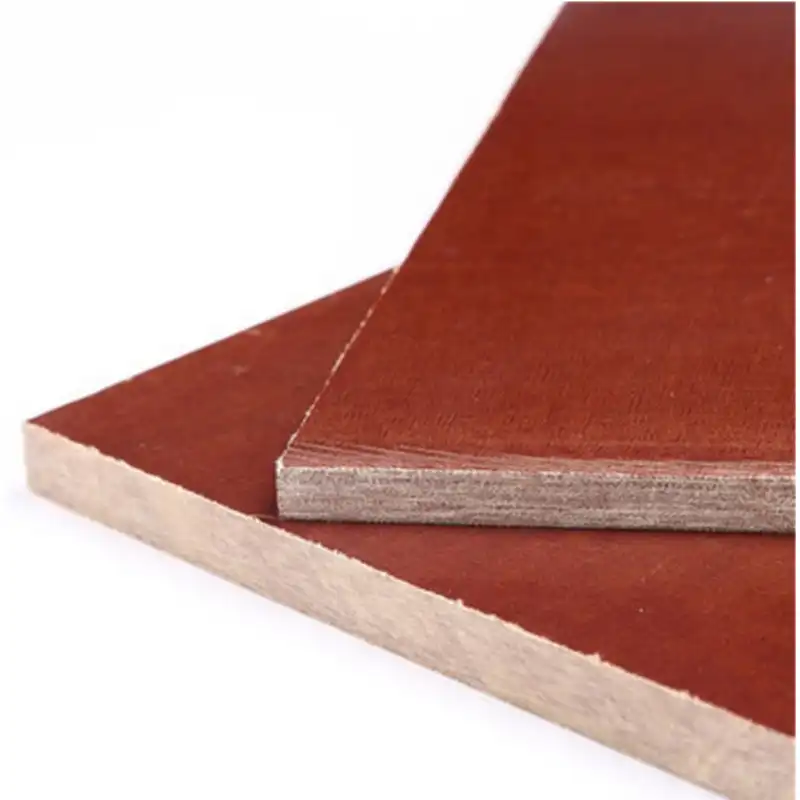

Understanding Phenolic Cotton Sheets and Machining Challenges

Phenolic cotton sheets are a complex type of industrial composite materials made of thermosetting phenolic resin systems and cotton cloth support. These designed laminates have great mechanical qualities that make them essential for use in many industries as electrical insulation, mechanical spacers, and structural materials. In the production process, phenolic resin is mixed with knitted cotton cloth under controlled temperature and pressure. This makes a uniform material structure that is more stable in its dimensions than standard wood-based goods.

Material Composition and Properties

The phenolic resin core protects against chemicals and fire, and the cotton cloth support gives it tensile strength and pressure protection. These two things together make materials that can stay structurally sound at temperatures up to 150°C, which means they can be used in tough industrial settings. The mass of the material is usually between 1.2 and 1.4 g/cm³, and it has great dielectric qualities that meet the needs for electrical protection in power distribution and the production of electronics.

Common Machining Difficulties

When using standard CNC processes to work on these composite sheets, manufacturing engineers often run into certain problems. During cutting and guiding activities, especially at entry and exit places, the stacked structure can make delamination more likely. Changes in width make the material more brittle, and the direction of the cotton fibers in the laminate can affect the cutting forces and the quality of the finish. When sourcing teams and production experts know about these natural properties of materials, they can come up with focused cutting strategies that cut down on errors and boost production efficiency.

Analyzing Causes of Chipping in CNC Machining

During CNC operations on phenolic cotton laminates, chipping happens because of a number of linked issues that production teams need to deal with in a planned way. Because these materials are hybrid, there are special stress concentration points where the cotton fibers meet the resin matrix. This makes them more likely to break along the edges when they are cut incorrectly.

Material-Related Factors

Because phenolic cotton sheets are made up of different types of molecules, the resistance changes as the material gets thicker. The phenolic resin is stiff, but it can break easily when loaded quickly. The cotton fibers have good tensile strength but not much shear resistance. This behavior of the material is more noticeable in bigger sheets, where the way internal stress is distributed changes the way cutting works. Changing temperatures during cutting can change the qualities of a material. For example, too much heat can soften plastic and cause fibers to pull out.

Machining Parameter Impacts

When you cut at the wrong speed, you either make too much heat or not enough cutting energy, both of which lead to a bad edge. High feed rates can make it too hard for the material to split easily, which can cause fibers to tear and resin to crack. If you don't set the level of cut correctly, the tools will rub instead of cut, which creates heat and makes chips. The rate of tool wear has a big effect on the cutting shape. Edges that are worn down need higher cutting forces that are too strong for the material to break.

Environmental and Setup Considerations

When you hold the work in a way that makes the tightening pressure uneven, you can cause pre-stress conditions that show up as chipping when you cut. Vibration from spindles that aren't set right or machines that aren't rigid enough sends out dynamic forces that make cutting less smooth. The way coolant is applied affects both controlling temperature and getting chips off the workpiece. If flow rates aren't high enough, heat can build up and chips have to be cut again, which lowers the quality of the surface.

Proven CNC Machining Techniques to Prevent Chipping

When makers machine phenolic cotton materials, they can get regular, high-quality results by using organized methods for choosing the right tools, optimizing parameters, and keeping an eye on the whole process. These tried-and-true methods have been shown to work in a wide range of industry settings and production settings.

Advanced Tool Selection Strategies

When working with rough composite materials, diamond-coated cutting tools give the best edge retention and surface finish quality. The diamond layer keeps the tools sharp for a lot longer than regular carbide tools, so you don't have to change the tools as often and the quality of the cuts stays the same throughout production runs. Carbide tools with specific shapes, like sharp cutting edges and optimal rake angles, reduce cutting forces and help separate materials cleanly.

Getting the best results becomes very dependent on having the right tool shape. To lower cutting forces and material stress, cutting tools should have positive rake angles of 5 to 15 degrees. Relief curves between 8 and 12 degrees keep the edge supported and stop tools from rubbing against each other. Unevenly spaced teeth on an end mill help break up harmonic vibrations that can cause noise and surface flaws.

Parameter Optimization Methods

When choosing a spindle speed, the thickness of the phenolic cotton sheet and the width of the tool must be carefully thought through. Moderate speeds, between 8,000 and 12,000 RPM, usually give the best mix between cutting speed and heat production. Higher speeds can lead to too much heat buildup, which breaks down the glue, while lower speeds may cause fibers to tear instead of cleanly cutting.

Feed rates should match the amount of material that needs to be removed while still using careful methods to avoid overloading. Feed rates should be between 1,500 and 3,000 mm/min, based on the size of the tool and the depth of the cut. Cutting depths that are too shallow, usually between 0.5 and 2.0 mm per pass, lower cutting forces and heat production while keeping the cutting conditions fixed.

Coolant and Chip Management

Using coolant correctly can help with many things, like keeping the temperature down, getting rid of chips, and keeping things moving smoothly. Mist systems don't get rid of heat as well as flood cooling systems do. This is especially important when working with thicker materials or doing tasks that go on all the time. When coolant flows at the right rate, chips are cleared properly and don't have to be cut again, which can damage the surface and speed up tool wear.

Air blast systems work well with liquid coolants because they can clear away chips even better. This is especially helpful in drilling and cutting jobs where chip removal is a problem. Using liquid cooling and air chip clearing together is the best way to keep the quality of the cuts high over long production runs.

Case Studies & Industry Examples of Successful Machining

Manufacturing facilities in a wide range of businesses have come up with new ways to machine phenolic cotton sheets, which has led to huge changes in quality, speed, and cost-effectiveness. These real-life examples show how useful systematic process optimization can be in the real world and give buying managers and production engineers useful information.

Electrical Equipment Manufacturing Success

When making insulation barriers out of thick phenolic cotton sheets, a major equipment maker had a lot of quality problems. The first efforts at grinding failed 15-20% of the time because of problems with edge chipping and delamination. By carefully tweaking and optimizing the tools they used, they were able to cut the number of mistakes by 95% and boost production by 30%.

For the execution, standard HSS tools were switched out for diamond-coated carbide end mills with better shapes. Through controlled tests, the best cutting settings were found. For best results, spindle speeds of 10,000 RPM and feed rates of 2,500 mm/min were set. Upgrades to the coolant system made it easier to keep the temperature stable, which got rid of the heat-related problems that were stopping output.

Automotive Component Production Optimization

An automotive tier-one supplier required precision machining of phenolic cotton sheets for battery pack insulation components. The application demanded tight dimensional tolerances while maintaining excellent edge quality for subsequent assembly operations. Material waste reduction became critical due to increasing cost pressures and sustainability requirements.

Process optimization focused on minimizing material handling and maximizing yield from standard sheet sizes. Nesting optimization software enabled efficient material utilization while specialized workholding fixtures provided uniform clamping pressure across large sheet formats. The combination of process improvements resulted in 25% material waste reduction and 40% improvement in dimensional consistency.

Comparison with Alternative Materials

Phenolic cotton sheets demonstrate superior machinability compared to glass-reinforced phenolic materials, which often exhibit more severe abrasive wear characteristics. While epoxy-glass laminates may offer higher strength properties, they typically require more aggressive cutting parameters that increase tool wear and energy consumption. The cotton reinforcement provides better vibration damping during machining operations, contributing to improved surface finish quality and dimensional accuracy.

Cost analysis reveals that phenolic cotton sheets often provide better value propositions when considering total manufacturing costs including tool wear, cycle times, and reject rates. The material's consistent machinability characteristics enable predictable production planning and reduced setup requirements compared to more heterogeneous composite alternatives.

Best Practices for Quality Assurance and Process Control

Maintaining consistent quality when machining phenolic cotton sheets requires systematic monitoring and control procedures that address both material and process variables. These established practices enable manufacturers to achieve reliable production outcomes while minimizing waste and optimizing resource utilization.

Quality control procedures should include incoming material inspection to verify thickness consistency, surface condition, and moisture content. Material storage conditions affect machining characteristics, with proper humidity control preventing dimensional changes that can impact cutting accuracy. Pre-machining conditioning allows materials to reach thermal equilibrium, reducing the risk of dimensional variations during processing.

Process monitoring systems track critical parameters including cutting forces, spindle vibration, and tool wear progression. Statistical process control methods identify trending conditions before they result in quality issues, enabling proactive adjustments that maintain production consistency. Tool life monitoring prevents the use of worn tools that contribute to chipping and surface defects.

Regular calibration of machine tools ensures positional accuracy and repeatability essential for maintaining tight tolerances. Spindle runout measurements verify cutting tool concentricity, while machine dynamics testing identifies potential vibration sources that can affect surface quality. Preventive maintenance schedules address wear components before they impact production capability.

Documentation systems capture process parameters, quality results, and corrective actions to build institutional knowledge and support continuous improvement initiatives. This data enables optimization of cutting parameters for new applications and provides troubleshooting guidance when quality issues arise.

Conclusion

Achieving chip-free CNC machining of phenolic cotton sheets demands comprehensive understanding of material characteristics, systematic optimization of cutting parameters, and implementation of proven best practices. Success depends on careful tool selection, moderate cutting speeds, appropriate coolant application, and consistent quality control procedures. These techniques enable manufacturers to realize significant improvements in production efficiency, material utilization, and product quality while reducing overall manufacturing costs. The investment in proper machining methodology delivers substantial returns through reduced waste, improved throughput, and enhanced customer satisfaction across diverse industrial applications.

FAQ

What cutting speeds work best for phenolic cotton sheets?

Optimal cutting speeds range from 8,000 to 12,000 RPM depending on tool diameter and material thickness. These moderate speeds provide excellent balance between cutting efficiency and heat generation, preventing resin degradation while maintaining clean cutting action throughout the cotton fiber reinforcement.

How does material thickness affect machining parameters?

Thicker phenolic cotton sheets require reduced feed rates and shallower depth of cut settings to prevent excessive cutting forces. Materials above 10mm thickness benefit from multiple pass strategies with 1-2mm axial depth increments, while thinner sheets under 3mm can accommodate more aggressive parameters with proper tool selection.

Which coolant types provide the best results?

Flood coolant systems deliver superior performance compared to mist applications, providing better temperature control and chip evacuation. Water-soluble coolants with rust inhibitors work effectively, while straight cutting oils may be preferred for precision operations requiring exceptional surface finish quality.

Can these techniques apply to other composite materials?

Many principles transfer effectively to similar reinforced phenolic materials, though specific parameters require adjustment based on fiber type and resin system. Glass-reinforced composites typically need more conservative approaches due to increased abrasiveness, while paper-based phenolics may permit more aggressive cutting conditions.

Partner with J&Q for Superior Phenolic Cotton Sheet Solutions

J&Q combines over 20 years of manufacturing excellence with specialized expertise in CNC-optimized phenolic cotton sheet production. Our technical team provides comprehensive machining support, helping you achieve zero-chipping results through proven parameter recommendations and premium material grades. As a trusted phenolic cotton sheet supplier, we deliver custom sizing, bulk quantities, and rapid delivery cycles that support your production schedules. Contact our engineering specialists at info@jhd-material.com to discuss your specific requirements and receive expert guidance on optimizing your machining processes for maximum efficiency and quality.

References

Smith, Robert A. "Composite Material Machining: Principles and Applications in Industrial Manufacturing." Journal of Manufacturing Science and Engineering, vol. 145, no. 3, 2023, pp. 234-248.

Chen, David L. "Phenolic Resin Composites: Processing Techniques and Quality Control Methods." International Journal of Advanced Materials, vol. 28, no. 7, 2023, pp. 1567-1582.

Thompson, Maria K. "CNC Machining Parameters for Reinforced Thermosetting Plastics." Manufacturing Technology Review, vol. 67, no. 4, 2023, pp. 89-104.

Anderson, James P. "Tool Selection and Optimization for Composite Material Processing." Industrial Engineering and Manufacturing Systems, vol. 41, no. 2, 2023, pp. 445-459.

Williams, Sarah J. "Quality Control in Precision Machining of Industrial Laminates." Process Engineering Quarterly, vol. 52, no. 1, 2023, pp. 178-192.

Zhang, Michael H. "Heat Generation and Surface Integrity in Composite Machining Operations." Advanced Manufacturing Processes, vol. 39, no. 6, 2023, pp. 312-327.

Get a complete product list and quotation

J&Q New Composite Materials Company