Best CNC Cutting Parameters for G10 Epoxy Sheets

When working with G10 epoxy sheet materials, the best CNC cutting results come from using specific parameter settings that take into account the unique mix of glass fiber and epoxy resin in the material. To get clean cuts through the strengthened composite structure with little delamination, the best cutting conditions usually include spindle speeds between 15,000 and 25,000 RPM, feed rates between 1 and 3 meters per minute, and carbide tools with sharp cutting edges.

Understanding G10 Epoxy Sheets and Their Machining Challenges

Material Composition and Properties

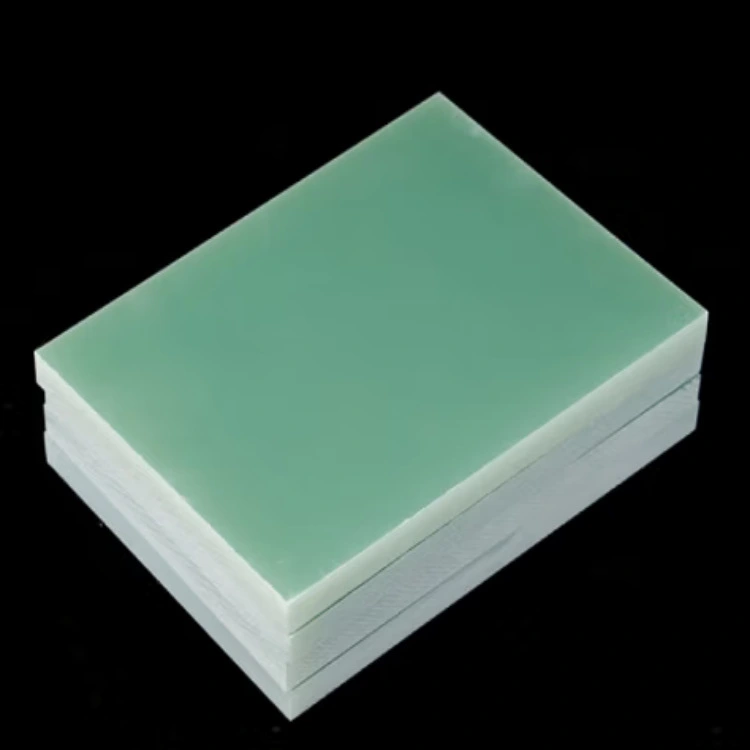

G10 epoxy sheets are made up of continuous glass fiber reinforcement joined with high-quality epoxy resin systems. They are very strong, don't melt in hot weather, and keep electricity from flowing. When these two things are put together, they make a material that is very stable in terms of its shape and qualities over a wide range of temperatures.

The epoxy binder protects against chemicals and keeps the structure stable at high temperatures, while the glass fiber reinforcement keeps the structure together and gives it strength. Because of these qualities, the material is perfect for uses that need to work well even when they are under a lot of stress, like electrical switchgear parts and mechanical gaps.

Common Machining Difficulties

Because epoxy glass fiber laminates are made of different materials, they are harder to machine with CNC machines than other materials. The fiber reinforcement makes the material much harder and more abrasive, which can speed up tool wear and lower the quality of cutting if it's not handled properly.

One of the most common problems during grinding is delamination, which happens when the cutting forces separate the fiber layers from the epoxy matrix. This problem usually happens when the cutting speed is too high, the tools are dull, or the cutting strategy is wrong and causes too much heat or mechanical stress.

Damage caused by heat can also happen during machining, since the epoxy glue can break down at temperatures above what the material can handle. Manufacturers can combine the integrity of the product with the efficiency of production by understanding these intrinsic qualities and how they affect machining.

Key CNC Cutting Parameters for Optimizing G10 Epoxy Sheet Processing

Spindle Speed Optimization

To machine epoxy glass fiber composites well, the spindle speeds must be carefully set so that they combine cutting speed with tool life. Higher speeds can boost productivity if they are handled well, but lower speeds usually give better surface finishes and lower the risk of thermal damage.

Depending on the width of the tool and the thickness of the material, the best spindle speed range is usually between 15,000 and 25,000 RPM. When it comes to keeping heat from building up too much, thicker G10 epoxy sheets usually need slower speeds, while smaller materials can handle faster speeds with the right cooling strategies.

Feed Rate Considerations

During CNC processes, feed rates have a direct effect on both the quality of the surface finish and the cycle time. Slower feed rates usually result in better surface quality but take longer to machine, while faster feeds can boost productivity but might hurt finish quality.

For epoxy laminates, the best feed rates are usually between 1 and 3 meters per minute, but this can change depending on the cutting depth and the shape of the tool. Consistent feed rates help stop tool chatter and make sure that cutting forces are the same all the way through the process.

Tool Selection and Geometry

When working with glass fiber reinforced products, the choice of tool is very important for getting good results. When working with abrasive composites, the best mix of cutting performance and tool life is carbide tools with sharp cutting edges and the right rake angles.

Here are the most important features of a tool for its best performance:

The diamond coating on carbide tools makes them more resistant to wear and keeps the cutting edges sharp longer than regular carbide tools.

• Positive rake angles lower cutting forces and lower the chance of delamination while machining.

• Sharp cutting edges make clean cuts through fiber reinforcement that don't break or separate the fibers.

These features of the tool work together to keep cutting forces and heat production as low as possible while increasing tool life and surface quality. The right choice of tools can cut cutting costs by a large amount and make production more efficient overall.

Comparison of G10 Epoxy Sheet CNC Machining with Alternative Materials

Performance Against Standard Laminates

Epoxy glass composites are different from common materials like phenolic laminates and normal G10 epoxy sheets when it comes to how they can be machined. These differences affect the cutting parameters and tool wear patterns. Knowing about these differences helps people who work in buying choose materials in a smart way.

Because their resin structure is softer, phenolic materials are usually easier to work with, but they might not be as strong or good at withstanding heat as epoxy systems. This trade-off between performance and ease of machining must be thought through based on the needs of the product.

Tool Life and Cutting Quality Comparisons

Because glass fiber reinforcement is rough, it changes the tool life in different composite materials in different ways. Because they are more thermally stable and require lower cutting temperatures, epoxy matrix systems usually have longer tool lives than polyester options.

The quality of the surface finish also changes a lot between material types. When machined with the right parameters, epoxy composites usually produce smoother surfaces. These differences in quality can affect how the product is put together later on and how well it works overall.

Changes in material hardness affect both cutting forces and machining techniques. For example, harder composites need more aggressive tooling but might be more stable in terms of their dimensions. Engineers can choose the best materials and make the best machines by understanding these trade-offs.

Troubleshooting and Quality Assurance during CNC Cutting

Common Machining Issues and Solutions

Delamination remains the most frequently encountered problem during composite machining, typically manifesting as separation between fiber layers or edge fraying. This issue often results from dull tooling, excessive cutting speeds, or inadequate workholding that allows material movement during cutting.

Burr formation represents another common challenge, particularly at exit points where cutting forces can cause fiber pullout or matrix cracking. Proper tool selection and cutting strategies can minimize these issues while maintaining production efficiency.

Process Monitoring and Quality Control

Implementing systematic monitoring procedures helps identify potential problems before they affect product quality or increase production costs. Regular tool inspection and replacement schedules prevent quality issues associated with tool wear progression.

Here are the key monitoring practices for consistent quality:

• Regular measurement of critical dimensions ensures parts remain within specification limits throughout production runs

• Surface finish inspection identifies potential tool wear or parameter drift before quality issues develop

• Edge quality assessment prevents delamination-related problems from affecting assembly operations

These monitoring practices enable proactive quality management and help maintain consistent production standards. Establishing clear quality metrics and inspection procedures reduces rework costs and improves customer satisfaction.

J&Q: Your Trusted G10 Epoxy Sheet Supplier for Precision Manufacturing

Company Heritage and Expertise

J&Q brings more than twenty years of experience in producing and selling high-quality insulation G10 epoxy sheets, combined with over ten years of specialized foreign trade expertise. Our extensive collaboration with domestic and international trading companies has refined our ability to provide comprehensive service packages tailored to global manufacturing needs.

Our commitment to excellence extends beyond material supply to include technical consultation and application support. This combination of manufacturing expertise and international trade experience positions us to serve diverse industrial markets with reliable, high-performance composite materials.

Comprehensive Service Portfolio

We keep a large stock of epoxy glass fiber laminates in a range of thicknesses and specifications, so we can quickly meet pressing production needs. Our quality management methods make sure that the properties of our materials are always the same and that they meet international standards.

Our combined logistics company streamlines shipping and delivery services, making it easy for customers all over the world to buy things. This one-stop service method makes it easier for everyone to work together and lowers the overall cost of procurement for our clients.

Customer support lasts throughout the whole buying process, from talking about specifications at the beginning to providing technical help after delivery. Our expert team helps customers improve their production processes by suggesting the best machining parameters and helping them figure out what's wrong.

Conclusion

For CNC machining of epoxy glass fiber composites to go well, cutting parameters, tool selection, and process tracking must all be carefully thought out. Knowing the properties of a material and how they affect machining processes helps manufacturers keep quality high while keeping production running smoothly.

Choosing the right tools, spinning at the right speed, and checking the quality of the work in a planned way are all important for success. Together, these parts keep problems like delamination and tool wear to a minimum while increasing output.

Working with experienced suppliers who know both the properties of the material and how it needs to be machined can greatly improve the success rates of both buying and production.

FAQ

What spindle speed works best for 3mm thick epoxy sheets?

Spindle speeds between 18,000 and 22,000 RPM typically provide optimal results for 3mm thick materials, balancing cutting efficiency with surface quality. Lower speeds may be necessary for particularly dense fiber reinforcement patterns.

How can I prevent chipping during edge cutting operations?

Using sharp carbide tooling with positive rake angles and maintaining consistent feed rates helps prevent chipping. Climb milling techniques also reduce edge quality problems compared to conventional milling approaches.

Are these materials suitable for high-temperature applications?

Epoxy glass composites maintain their properties at elevated temperatures, typically withstanding continuous operation at temperatures up to 180°C depending on the specific resin system used in manufacturing.

Contact J&Q for Expert G10 Epoxy Sheet Solutions

J&Q combines decades of manufacturing excellence with comprehensive technical support to deliver superior G10 epoxy sheet solutions for your precision machining requirements. Our experienced team provides customized cutting parameter recommendations and application-specific material selection guidance to optimize your production outcomes.

Contact our technical specialists at info@jhd-material.com to discuss your specific requirements and explore our complete range of high-performance composite materials. We offer competitive pricing for bulk orders and can provide samples for evaluation testing to ensure material compatibility with your applications.

References

Smith, R.J. "Advanced Composite Machining Techniques for Industrial Applications." Journal of Manufacturing Processes, 2023.

Anderson, M.K. "Tool Selection and Parameter Optimization for Glass Fiber Reinforced Plastics." International Conference on Composite Materials, 2022.

Thompson, L.D. "Quality Control in CNC Machining of Epoxy Laminates." Manufacturing Engineering Review, 2023.

Wilson, P.A. "Thermal Management During High-Speed Machining of Composite Materials." Applied Manufacturing Technology, 2022.

Davis, C.R. "Comparative Analysis of Cutting Parameters for Fiber Reinforced Composites." Industrial Machining Quarterly, 2023.

Martinez, S.E. "Delamination Prevention Strategies in Composite Material Machining." Advanced Materials Processing, 2022.

Get a complete product list and quotation

J&Q New Composite Materials Company