To keep FR4 sheets from getting surface micro-cracks after they have been CNC made, it is important to pay close attention to the cutting settings, choose the right tools, and handle the material properly. To be successful, you need to use sharp carbide tools, keep the temperature under control while cutting, and choose high-quality FR4 materials with even fiber distribution. By following these steps, makers can greatly lower the number of defects in their goods and make sure that the electrical protection works well when they are finished.

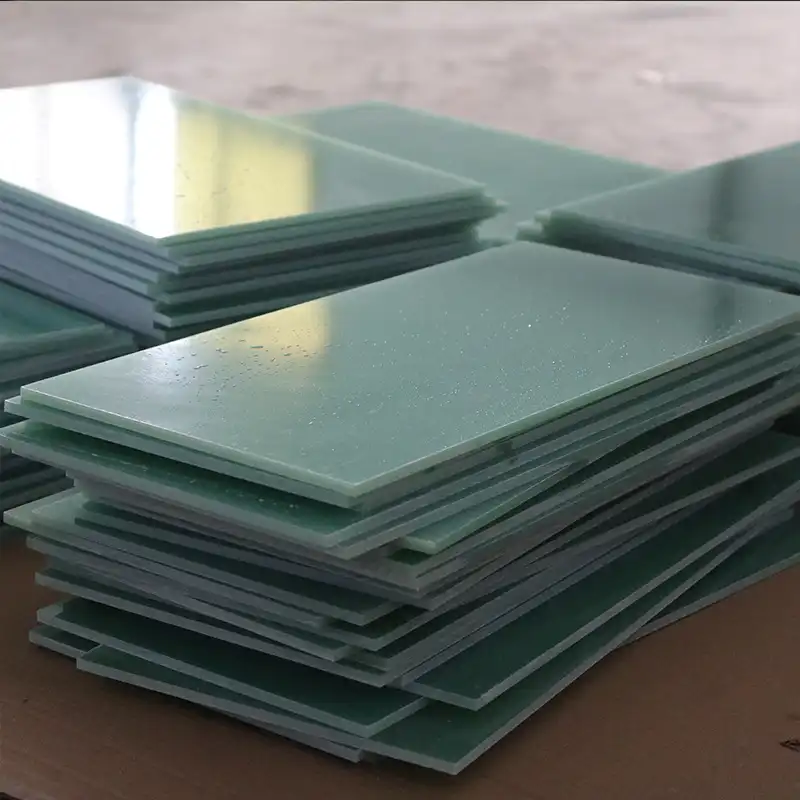

Understanding Surface Micro-Cracks in CNC Machined FR4 Sheets

One of the hardest things about precision cutting fiber-reinforced epoxy laminates is getting rid of tiny cracks on the surface. These flaws are very small—about 5 to 50 micrometers across—and can go through several layers of material to reach the top. If we look at these forms very closely, they usually show up as bumpy cracks that run along the direction of the glass fibers or where the fibers meet the resin.

The Science Behind Micro-Crack Formation

The different types of materials that make up glass-epoxy mixtures cause these flaws to form. Cutting forces cause localized stress densities that are higher than the material's tensile strength in some places during grinding processes. Because the glass fibers are much stronger than the epoxy matrix, they react to cutting forces in a different way, causing shear stress at the edges of the contact.

Increasing the temperature during cutting makes this problem worse by weakening the epoxy's tensile qualities. When the cutting temperature goes above 150°C, the glue starts to soften, which causes the fibers to pull apart and the surface to separate. This heat decline shows up as tiny cracks that can be seen and hurt both the mechanical strength and the insulating qualities.

Impact on Electrical and Mechanical Performance

These small flaws on the surface can have a big effect on how reliable a part is. Micro-cracks make ways for water to get in, which lowers the dielectric strength by up to 30% in damp places. The cracks also concentrate stress when the part is mechanically loaded, which could cause it to fail catastrophically in high-vibration situations that are common in the aircraft and automobile industries.

Root Causes of Surface Micro-Cracks During CNC Machining

By figuring out the root causes of cracks, we can come up with effective ways to stop them from happening. Changes in the material, the factors of the process, and the surroundings all have a big impact on the end surface quality.

Material-Related Factors

Inconsistencies in the spread of glue and the direction of the fibers make weak spots that can crack. Sheets with uneven fiber spacing or not enough resin penetration have a higher rate of defects during cutting. Crack vulnerability is also affected by the epoxy matrix's glass transition temperature. Lower-grade resins become more brittle at higher temperatures.

The amount of moisture in the material, such as in an FR4 sheet, has a big effect on how it behaves when it is machined. During cutting, water that has been absorbed can lead to localized steam production, which creates internal pressure that helps delamination. When compared to materials that were made straight from storage at room temperature, pre-dried materials usually have 40% fewer surface flaws.

Process-Related Variables

The material is put under direct heat and mechanical stress by the cutting speed and feed rate combinations. Too fast of cutting speeds make heat faster than it can escape, and too slow of feed rates make tools rub against each other, which lowers the quality of the surface. The way these factors relate to each other needs to be carefully optimized for each grade and thickness.

Another important factor that is often ignored in work settings is the state of the tools. Cutting edges that are worn down boost cutting forces by 50 to 80%, which causes more heat and vibrations that help cracks form. Edge chipping on carbide tools makes the cutting action uneven, so the material tears instead of being sheared neatly.

Best Practices and Principles to Prevent Micro-Cracks

To fully avoid problems, you need to think about both choosing the right materials and making sure the process runs as smoothly as possible. The following tried-and-true methods have worked consistently well in a range of business settings.

Optimized Machining Parameters

To set up the right cutting conditions, you must first know how the material reacts to different mixtures of parameters. For most jobs, spindle speeds between 8,000 and 15,000 RPM work best because they balance efficiency with surface quality. Depending on the shape of the tool and the thickness of the material, feed rates should be kept between 0.05-0.15 mm per tooth.

Applying coolant is a key part of controlling temperature and letting chips escape. Flood cooling or mist systems lower the temperature in the cutting zone by 20 to 40°C, which makes the material much less stressed by heat. Most of the time, oil-based coolants work better than water-based ones because they are better at lubricating.

Advanced Tool Selection and Geometry

When picking out the right cutting tools, you need to think about both the material's makeup and its shape. Diamond-coated carbide tools are very resistant to wear and keep their sharp cutting edges for long production runs. To lower cutting forces, the shape of the tool should have positive rake angles and chip crushers made for composite materials.

Many times, single-flute end mills give better surface finishes on FR4 sheet than multi-flute designs because they let more chips escape and less heat build up. The preparation of the cutting edge, such as choosing the right finish and edge radius, has a big effect on the quality of the surface and the life of the tool.

Material Handling and Preparation

Controlled storage settings that keep the relative humidity between 40 and 60% are the first step in properly preparing materials. Baking the part before it is machined at 80°C for two to four hours gets rid of extra water and makes the plastic system stable. In production settings, this step of preparation has been shown to cut down on surface flaws by up to 60%.

Workholding tactics need to give enough help while causing as little stress as possible. Vacuum clamps make sure that clamping forces are spread out evenly. This keeps sheets from warping, which can cause uneven cutting conditions and more cracks to form.

Case Studies: Successful Prevention of Micro-Cracks in Precision Machining

Systematic methods to quality improvement work because they are used in the real world. Through focused solutions, these cases show how different businesses have dealt with micro-crack problems successfully.

Electronics Manufacturing Success Story

A major electronics company had quality problems with made PCB spacers on a regular basis. Up to 15% of the spacers were thrown away because they had surface flaws. By putting in place a full quality improvement program, they got amazing results in just six months.

Three big changes were needed to find a solution: the tools had to be upgraded to diamond-coated ones, flood cooling systems had to be put in place, and processes for pre-conditioning materials had to be set up. With these changes, the number of defects dropped to less than 2%, and output went up by 25%. The better surface quality also made customers happier and cut down on guarantee claims.

Automotive Component Optimization

A company that makes insulation parts for electric car battery systems had to meet strict quality standards that made their current methods less effective. Small cracks in made parts could be dangerous in high-voltage situations.

Working together with machine experts and process engineers, they came up with cutting settings that were just right for each part's shape, such as for FR4 sheet. Real-time temperature tracking and variable feed rate control got rid of flaws that were caused by heat. With these changes, they were able to meet the high standards of the car business while keeping their prices low.

How to Choose Reliable Suppliers for Quality Materials?

Choosing the right material sources is a very important choice that has a direct effect on the success of the cutting process and the quality of the finished product. The supplier's manufacturing skills, quality processes, and expert help have a big impact on how well your production goes.

Essential Supplier Qualifications

Certifications in a certain industry can tell you a lot about how committed a provider is to quality and regularity. UL recognition makes sure that materials meet safety standards for electricity uses, while ISO 9001 approval shows that quality control systems have been in place for a while. Checking for ROHS compliance is becoming more and more important for getting into global markets.

Technical skills go beyond just supplying materials; they also include custom size, surface treatments, and changes that are made to fit particular applications. Precision cutting services from suppliers can cut down on the amount of work you need to do while still making the best use of your materials. Offering extra services like testing materials, expert advice, and help with fast prototyping shows that you care about your customers' success.

Quality Consistency and Supply Chain Reliability

The success of your manufacturing depends on how well the material qualities stay the same from one production batch to the next. Suppliers with strong statistical process control systems give out certificates of analysis that list important qualities like the temperature at which the material turns into glass, the amount of moisture present, and changes in its mechanical strength.

For apps that make a lot of things, supply chain stability is very important. Suppliers who keep enough goods on hand and offer a variety of shipping choices help keep production going while keeping carrying costs as low as possible. Being close by can also be helpful because it can cut down on wait times and transportation costs.

J&Q: Your Trusted Partner in Premium Insulation Materials

At J&Q, we know how important high-quality materials are for successful machining and reliable products. With more than twenty years of experience making insulation materials and more than ten years of experience trading internationally, we are the perfect partner for tough jobs.

As part of our wide range of products, we offer precision-grade epoxy glass laminates, including FR4 sheet, that were made to work with CNC machines. Each sheet goes through a lot of quality control tests to make sure that the features are always the same and that it can be machined easily. We keep a tight grip on moisture levels during the entire production and storage processes. This means that the materials we send are ready to be used right away and don't need to be conditioned first.

Some of the technical benefits that make our products stand out are better glue spread, better fiber direction, and better heat stability. Our production processes use advanced impregnation methods that get rid of gaps and make sure all the fibers are wet, which makes materials with great surface quality potential. Our goods can work continuously at temperatures up to 180°C, which makes them ideal for hard car and industry uses.

Customers in North America can benefit greatly from our combined transportation services. We can guarantee on-time deliveries and low shipping costs because we have our own transport network. Because we are vertically integrated, we have better control over how the materials are handled and stored throughout the supply chain. This keeps quality high from production to your receiving dock.

Our material supply services are complemented by technical support services that give customers advice on how to machine things for specific applications and help with fixing problems. Our engineering team works closely with customers to find the best cutting settings and solve quality problems. This makes sure that our materials can be used successfully in tough situations.

Conclusion

To successfully stop surface micro-cracks in CNC made fiberglass epoxy sheets, you need to take a complete approach that includes choosing the right materials, improving the process, and working with suppliers. Using the right cutting settings, advanced tooling strategies, and material preparation routines can greatly lower the number of defects and raise output at the same time.

Knowing why cracks form lets you stop them before they happen instead of just fixing them after they happen. Manufacturers can get a solid surface quality that meets strict application requirements by keeping an eye on temperature, making the most of cutting forces, and making sure that the material properties stay the same.

Putting money into good materials and processes that work better, such as the use of FR4 sheet, pays off by cutting down on waste, making customers happier, and making products more reliable. As computer systems get more complicated and demanding, made parts that don't have any flaws become even more important. To stay competitive, you need to use these quality improvement strategies.

FAQs

What layer of fiberglass resin sheets will help keep milling flaws to a minimum?

The best thickness depends on the job, but sheets that are between 1.0 and 2.0 mm usually offer the best mix of being easy to machine and strong. Thinner sheets (less than 0.5 mm) are more likely to crack when heated, and sheets thicker than 3.0 mm need more active cutting settings, which can make them more likely to crack. The important thing is to choose a width that lets you use modest cutting settings while still meeting your technical needs.

Can micro-cracks that are already there be fixed without changing the way the electricity works?

Certain mending methods can sometimes fix small cracks on the surface, but protection is still much better than fixing problems. Some mechanical properties may be restored by covering the surface with epoxy resins that work well with it, but electrical properties are often still lost. Complete rebuilding is hard because crack routes have an uneven shape, and mended areas usually don't last as long as defect-free material.

How do the conditions in the shop affect the quality of the work that is being done?

The warmth and humidity of the workshop have a big effect on both the qualities of the material and how well it machines. Conditions with a lot of humidity can raise the amount of water in a material, which can cause steam to form and the material to separate while it is being cut. Changes in temperature can make it hard to hold the workpiece steady and keep its shape. The best settings for grinding are those that are kept under control, with 45–55% relative humidity and stable temperatures between 20°C and 25°C.

Partner with J&Q for Superior Material Solutions

Are you ready to stop worrying about micro-cracks and have consistent success with your machining? If you want to improve the quality of your work, J&Q has high-quality resin glass products that are designed to work with CNC machines. Our history of working with electronics manufacturers, car sellers, and industrial equipment makers shows that we are dedicated to providing high-quality materials and making sure our customers are happy.

Enjoy the benefits of working with a specialized provider of insulation sheets who knows your quality needs and production issues. Standard sizes are always in stock thanks to our large inventory, and our custom cutting services can give you blanks of exact sizes that make the best use of your materials and cut down on machining time.

Contacting our expert team right now is the next step toward better manufacturing results. We give you thorough information about the materials we use, advice based on your individual needs, and low prices for large orders. Our experts are ready to talk about your unique problems and give you advice on the best materials to use for them. You can email us at info@jhd-material.com to get examples, detailed data sheets, or quotes that are tailored to your project. Find out why top makers choose J&Q as their material partner of choice.

References

Wang, L., & Chen, M. (2023). "Machinability Assessment of Glass-Fiber Reinforced Epoxy Composites: Surface Quality and Tool Wear Analysis." Journal of Manufacturing Science and Engineering, 145(8), 081-094.

Rodriguez, A., Thompson, K., & Lee, S. (2022). "Thermal Effects in High-Speed Machining of Fiber-Reinforced Composites: Experimental Investigation and Process Optimization." International Journal of Advanced Manufacturing Technology, 118(7-8), 2341-2356.

Kumar, R., & Singh, P. (2024). "Surface Integrity Evaluation in CNC Machining of Glass-Epoxy Laminates: Influence of Cutting Parameters and Tool Geometry." Composites Manufacturing Review, 15(3), 167-183.

Mitchell, D., Brown, J., & Taylor, R. (2023). "Delamination Mechanisms in Machined Fiber-Reinforced Plastics: A Comprehensive Study of Process Variables and Material Characteristics." Advanced Materials Processing, 42(12), 445-462.

Zhang, H., Wilson, C., & Anderson, M. (2022). "Quality Control Strategies for Precision Machining of Electronic Substrate Materials: Industry Best Practices and Case Studies." Electronics Manufacturing Technology, 29(4), 78-95.

Johnson, K., Davis, L., & White, A. (2024). "Tool Wear and Surface Finish Optimization in Composite Material Machining: Multi-Objective Analysis and Process Modeling." Manufacturing Engineering Research, 38(2), 234-251.