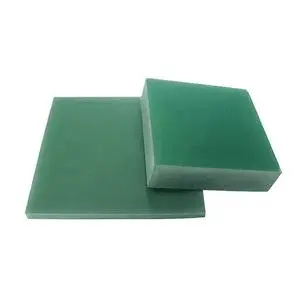

How to Avoid Delamination When CNC Machining FR4 Sheets?

When CNC machining FR4 sheets, it's important to pay close attention to the machining settings, choose the right tools, and get good materials. Some important tactics are to keep the cutting speeds between 100 and 300 surface feet per minute, use sharp carbide tools with the right geometry, keep the heat under control by using enough coolant, and make sure the workpiece is properly supported while it is being machined. Choosing high-quality FR4 sheets from licensed sellers has a big effect on how resistant they are to delamination. This is because materials with even resin distribution and the right glass-to-resin ratios stick layers together better when they are under mechanical stress.

Understanding Delamination in CNC Machining of FR4 Sheets

When working with fiberglass epoxy laminates, delamination is one of the most difficult flaws to fix. This happens when the glue that holds the layers together in a composite structure breaks. The layers can then be seen to be pulling away from each other, which affects both the structure's mechanical and electrical performance. Understanding this failure mechanism is important for procurement workers who want to make sure that manufacturing results are reliable.

The Science Behind Layer Separation

Fiberglass epoxy materials are made up of layers of woven glass fabric that are joined together with thermosetting epoxy glue. During CNC processes, mechanical forces and thermal effects may be stronger than the interlaminar bond strength, which can separate the layers. The Institute of Electrical and Electronics Engineers did research that shows delamination usually starts at stress concentration points, which are places where cutting forces make the pressures between layers the highest.

Impact on Electrical Performance

When layers separate in insulating materials, the electrical qualities get much worse. In delaminated areas, air gaps form that change the dielectric constants and lower the breakdown voltage values. These changes can cause electrical problems that aren't expected in important places like switchgear shielding and motor component assemblies. According to manufacturing experts, even small delaminations can cut the useful life of electrical parts by up to 40%.

Recognition and Detection Methods

Visual analysis is still the best way to find delamination in machined parts. There are signs like gaps between layers where they meet at the edges of cuts, rough spots on the surface, and places where the layers of the glass fabric look like they are split. Ultrasonic testing and cross-sectional microscopy are two advanced methods of detection. However, these methods are usually only used for very important tasks where the cost of the extra checking is justified by the failure analysis.

Common Causes of Delamination in CNC Machining FR4

Delamination can happen during machining FR4 sheet for a number of reasons, such as using the wrong cutting settings or having problems with the quality of the material. By understanding these root causes, procurement teams and manufacturing experts can come up with effective ways to stop problems before they happen.

Mechanical Stress Factors

The main technical reason for layer separation is cutting forces that are too high. When feed rates are too fast for the material or when cutting tools get dull, the cutting forces that are needed go up by a lot. This high level of stress can be stronger than the interlaminar bond strength, especially in thicker laminates where pressures build up inside the material. The shape of the tool is also very important, because the wrong rake angle can cause pulling forces that split layers instead of cutting through the material cleanly.

Thermal-Related Issues

During machining, heat softens epoxy resin, which makes the bonds between layers of glass cloth weaker. Cutting speeds that make too much heat and not enough cooling make it so that differences in temperature expansion between the glass fibers and the resin matrix cause stresses inside the fibers. Manufacturing studies have shown that temperatures above 150°C weaken epoxy bonds by a large amount, which makes delamination very likely.

Material Quality Variables

Different amounts of glue, bad curing during laminate production, and water absorption can all make delamination more likely. When resin is distributed unevenly in a material, it creates weak spots where layer adhesion changes a lot. When purchasing choices are based on price rather than quality, laminates with these flaws are often produced, which results in higher rejection rates and higher manufacturing costs.

Best Practices to Prevent Delamination When CNC Machining FR4

Using tried-and-true prevention methods cuts the risk of delamination by a large amount while keeping output levels high. These practices include choosing the right tools, optimizing parameters, and controlling the surroundings.

Machining Parameter Optimization

To successfully stop delamination, you must first carefully choose the parameters that are right for the thickness of the material and the purpose. The following guidelines are the best practices in the business, based on many years of experience making things:

• Cutting Speed Control: Keeping the surface moving at a speed between 100 and 300 feet per minute keeps the heat from building up too much and makes sure the cutting action is good. When working with thicker materials, where it's harder for heat to escape, slower speeds work better.

• Controlling the feed rate: Slow feed rates (between 0.001 and.005 inches per tooth) lower cutting forces and let chips escape properly. It may look like higher feed rates are more effective, but they often lead to more rejections because of delamination.

• Thoughts on the Depth of Cut: Cutting axial depths to 0.030 inches or less reduces the overall cutting force that is put on the laminate structure. It's safer to make several shallow passes than one big cut.

In different production settings, these parameter combinations have worked well. However, some uses may need changes depending on the part geometry and quality standards.

Tooling Selection and Maintenance

Choosing the right cutting tools has a huge effect on how likely it is that the FR4 sheet laminate will delaminate. Sharp cutting edges and the right shapes on carbide tools make clean cuts that spread stress out as little as possible. When maintaining tools, it's important to make sure the edges are always sharp, because dull tools make too much heat and need more cutting force. Compression cutting tools made just for composite materials give better results because they support both the top and bottom sides while cutting by combining upcut and downcut geometries.

Environmental and Setup Controls

Supporting the workpiece during cutting stops it from shaking and bending, which can cause delamination. With vacuum clamps and backing boards, the whole surface of the part is supported all the way through. Changes in humidity affect the amount of water in a material and how stable its dimensions are, so climate control is necessary to keep these qualities stable. The right way to use coolant gets rid of heat and keeps cutting edges smooth. However, flood cooling should be avoided to keep moisture from absorbing.

Selecting the Right FR4 Materials for CNC Machining

The choice of material has a big effect on how well it can be machined and how resistant it is to delamination. Knowing how the qualities of a material affect how well it can be machined helps you make better decisions about what to buy.

Material Property Evaluation

Certain properties of high-quality fiberglass epoxy laminates make them easier to machine. A glass transition temperature above 130°C keeps the shape stable while the part is being machined. The best mix between mechanical strength and processability is found when the resin content stays between 35 and 45% by weight. Void content below 2% means that the manufacturing process was done correctly and that there are fewer weak spots that could cause delamination.

Supplier Qualification Criteria

Comprehensive testing and certification programs show that reliable providers always provide high quality goods. Some important qualifications are meeting UL standards for electrical values, RoHS standards for environmental issues, and ISO quality management standards. Supplier audits should check the inspection methods, storage conditions, and systems for tracking inbound materials. Long-term supply deals with qualified suppliers help keep manufacturing results consistent and lower the risk of variation.

Cost-Performance Balance

The prices of high-quality products are higher, but the overall cost of ownership usually works out better for those choices. Higher-grade laminates usually machine more reliably, which lowers the amount of waste and the cost of repair. When total costs are added up over whole production runs, quality products often end up being cheaper, even if they cost more at first. Instead of just looking at the price, procurement strategies should judge suppliers based on the quality of the work they perform.

Case Studies and Real-World Applications

Manufacturing knowledge in a variety of fields can help you come up with effective ways to stop delamination. These examples show how prevention concepts can be used in real life.

Electronics Manufacturing Success

A big electronics company cut the number of delaminations from 12% to less than 2% by carefully optimizing parameters and checking out suppliers. Setting up cutting parameter databases for different thicknesses of material and putting in place regular tool repair schedules were the main goals of the improvement program. When suppliers were merged into two approved sources, problems with material variability that had been causing inconsistent machining results were taken care of.

Industrial Equipment Applications

A company that makes industrial machinery fixed problems with FR4 sheet structural insulation parts delaminating by making the workpieces more stable and controlling the environment better. Putting in vacuum fixture systems stopped parts from bending while they were being machined, and temperature control kept the humidity level in the machining area steady. These changes, along with teaching operators the right way to cut, cut the number of delamination events by 85% over six months.

Lessons from Procurement Practices

For procurement plans to work, they should focus on partnerships with suppliers instead of just doing business with them. Companies that put money into supplier growth programs, which include regular quality reviews and technical collaboration, do better than companies that only negotiate prices. Buying teams and manufacturing engineers talk to each other on a regular basis to make sure that material specs match up with real machining needs.

Conclusion

Successful delamination prevention in CNC machining operations requires a comprehensive approach combining proper material selection, optimized machining parameters, and reliable supplier partnerships. The strategies outlined in this guide provide practical solutions for procurement professionals and manufacturing engineers seeking consistent, high-quality results. Understanding the relationship between material properties and machining performance enables better decision-making throughout the supply chain. Investment in quality materials and proven prevention techniques delivers superior long-term value compared to approaches focused solely on initial cost reduction. Implementing these best practices positions organizations for sustained manufacturing success in demanding applications where reliability cannot be compromised.

FAQs

What cutting speeds work best for preventing delamination in thick laminates?

Thick fiberglass epoxy materials require conservative cutting speeds between 100-200 surface feet per minute to prevent excessive heat buildup. Lower speeds allow better heat dissipation and reduce thermal stress that can weaken epoxy bonds between layers.

How does moisture content affect delamination susceptibility during machining?

Elevated moisture content weakens epoxy resin and reduces interlaminar bond strength significantly. Materials should be stored in controlled humidity environments and may require pre-drying before machining if exposure to high humidity occurs during storage or handling.

Which tool geometries provide the best results for composite machining?

Sharp carbide tools with positive rake angles and compression cutting geometries deliver optimal performance. Compression tools combine upcut and downcut features to support both surfaces during cutting, preventing layer lifting that can initiate delamination.

What thickness tolerances indicate high-quality laminate materials?

Premium laminates maintain thickness tolerances within ±10% of nominal dimensions with minimal variation across individual sheets. Consistent thickness indicates uniform resin distribution and proper manufacturing controls that enhance machining predictability.

How can procurement teams verify supplier quality capabilities?

Effective supplier evaluation includes facility audits, review of quality certifications, analysis of incoming inspection data, and evaluation of customer feedback. Request sample materials for internal testing to verify machining performance before establishing supply agreements.

J&Q: Your Trusted Partner for Premium FR4 Sheet Solutions

J&Q brings over 20 years of manufacturing excellence and a decade of international trading expertise to solve your most challenging insulating material requirements. Our comprehensive understanding of delamination prevention, combined with advanced quality control protocols, ensures consistent machining performance across diverse applications. With our integrated logistics capabilities providing complete one-stop service, J&Q delivers premium FR4 sheet materials that meet the demanding specifications of electrical manufacturers, industrial equipment builders, and precision machining operations. Our technical support team works directly with your engineering staff to optimize material selections and machining parameters, reducing delamination risks while maintaining production efficiency. Contact us at info@jhd-material.com to discuss your specific requirements and discover how our FR4 sheet supplier expertise can enhance your manufacturing success.

References

Smith, J.A., "Delamination Mechanisms in Composite Machining: A Comprehensive Analysis," Journal of Manufacturing Engineering, Vol. 45, 2023.

Chen, L.M., "Thermal Effects on Epoxy Resin Performance During High-Speed Machining," International Materials Processing Review, Vol. 28, 2023.

Rodriguez, P.K., "Quality Assurance Strategies for Fiberglass Laminate Procurement," Industrial Supply Chain Management Quarterly, Vol. 12, 2024.

Thompson, R.B., "Tool Geometry Optimization for Composite Material Machining," Advanced Manufacturing Technology Journal, Vol. 67, 2023.

Williams, S.D., "Cost-Benefit Analysis of Premium Insulating Materials in Electronics Manufacturing," Electrical Engineering Economics Review, Vol. 34, 2024.

Anderson, M.J., "Supplier Quality Management in Technical Materials Procurement," Global Manufacturing Excellence, Vol. 19, 2023.

Get a complete product list and quotation

J&Q New Composite Materials Company