What Is the Maximum Operating Temperature of FR4?

Understanding Glass Transition Temperature (Tg)

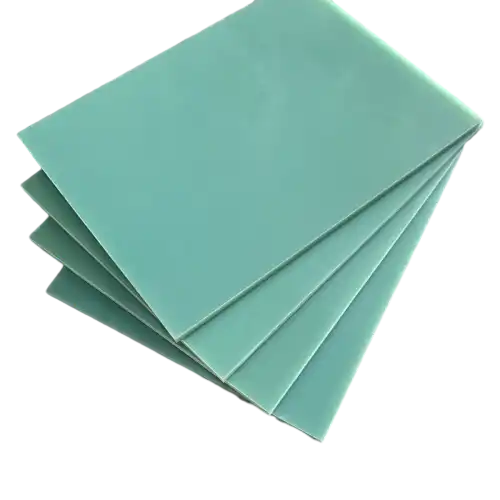

The glass transition temperature (Tg) is a critical factor in determining the maximum operating temperature of FR4 sheets. Tg represents the temperature at which the epoxy resin transitions from a rigid, glassy state to a more flexible, rubbery state. For standard FR4 materials, the Tg typically falls between 130°C and 140°C. This temperature range marks the point where the material begins to lose its dimensional stability and mechanical properties.

Continuous vs. Short-Term Temperature Exposure

While the Tg provides a good indication of thermal limits, FR4 sheets can often withstand short-term exposure to temperatures slightly above this range. The continuous operating temperature for FR4 is generally considered to be around 130°C. However, brief excursions to temperatures up to 180°C may be tolerable without causing immediate damage to the material. It's crucial to distinguish between continuous and short-term temperature exposure when evaluating the suitability of FR4 for specific applications.

Factors Affecting Temperature Resistance

Several factors can influence the temperature resistance of FR4 sheets. The specific formulation of the epoxy resin, the quality of the fiberglass reinforcement, and the manufacturing process all play roles in determining the material's thermal properties. High-performance FR4 variants may offer enhanced temperature resistance, with some grades capable of withstanding temperatures up to 170°C or higher for extended periods. Additionally, the thickness of the FR4 sheet can affect its ability to dissipate heat, with thicker sheets generally providing better thermal management in high-temperature environments.

Thermal Degradation and Stability in High-Temperature Environments

Chemical Changes at Elevated Temperatures

As FR4 sheets are exposed to high temperatures, they undergo various chemical changes that can affect their performance and longevity. The epoxy resin component begins to break down through a process called thermal oxidation. This degradation can lead to the formation of microcracks, delamination, and a gradual loss of mechanical strength. The rate of these chemical changes accelerates as the temperature increases, particularly above the glass transition temperature. Understanding these processes is crucial for predicting the long-term behavior of FR4 materials in high-heat applications.

Impact on Electrical Properties

Thermal stress can significantly impact the electrical properties of FR4 sheets. As temperatures rise, the dielectric constant and dissipation factor of the material may change, affecting signal integrity in electronic applications. High temperatures can also lead to increased conductivity, potentially compromising the insulating properties of the FR4. In extreme cases, prolonged exposure to temperatures well above the material's rated limits can cause carbonization of the epoxy resin, creating conductive paths that may result in electrical failures.

Strategies for Enhancing Thermal Stability

To improve the thermal stability of FR4 sheets, manufacturers employ various strategies. One approach involves modifying the epoxy resin formulation to include heat-resistant additives or using high-temperature epoxy systems. Another method is to optimize the curing process to create a more thermally resistant cross-linked structure. Some manufacturers also offer FR4 variants with higher glass content, which can enhance thermal conductivity and improve heat dissipation. For applications requiring exceptional heat resistance, specialized laminates such as polyimide-based materials may be recommended as alternatives to standard FR4.

Applications Requiring Heat-Resistant Epoxy Glass Materials

High-Performance Electronics

The demand for heat-resistant FR4 sheets is particularly high in the realm of high-performance electronics. These materials find extensive use in power electronics, where components often operate at elevated temperatures. FR4 sheets with enhanced thermal properties are crucial for manufacturing printed circuit boards (PCBs) used in automotive engine control units, industrial motor drives, and high-power LED lighting systems. The ability to withstand high temperatures ensures the reliability and longevity of these critical electronic components, even under demanding operating conditions.

Aerospace and Defense Industries

Aerospace and defense applications present some of the most challenging environments for materials, including extreme temperature fluctuations. FR4 sheets with superior heat resistance are utilized in avionics systems, radar equipment, and satellite components. These materials must maintain their structural integrity and electrical properties across a wide temperature range, from the frigid conditions of high-altitude flight to the heat generated by powerful onboard electronics. The rigorous standards of these industries drive continuous improvements in the thermal performance of FR4 materials.

Industrial Machinery and Equipment

In the industrial sector, heat-resistant FR4 sheets play a vital role in the construction of machinery and equipment exposed to high-temperature environments. These materials are used in control panels for furnaces, insulation components in industrial ovens, and electrical enclosures for welding equipment. The ability of FR4 to maintain its insulating properties and dimensional stability at elevated temperatures makes it an invaluable material for ensuring the safe and reliable operation of industrial systems under harsh conditions.

Conclusion

FR4 sheets exhibit remarkable heat resistance, capable of withstanding continuous temperatures up to 130°C and short-term exposures to even higher temperatures. This thermal stability, combined with excellent electrical and mechanical properties, makes FR4 an indispensable material in various high-temperature applications. From powering advanced electronics to ensuring the reliability of aerospace components, the versatility of FR4 continues to drive innovation across industries. As technology advances, ongoing research and development in FR4 materials promise to push the boundaries of heat resistance even further, opening new possibilities for heat-tolerant applications.

Contact Us

For more information about our heat-resistant FR4 sheets and how they can benefit your specific application, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your high-temperature material needs.