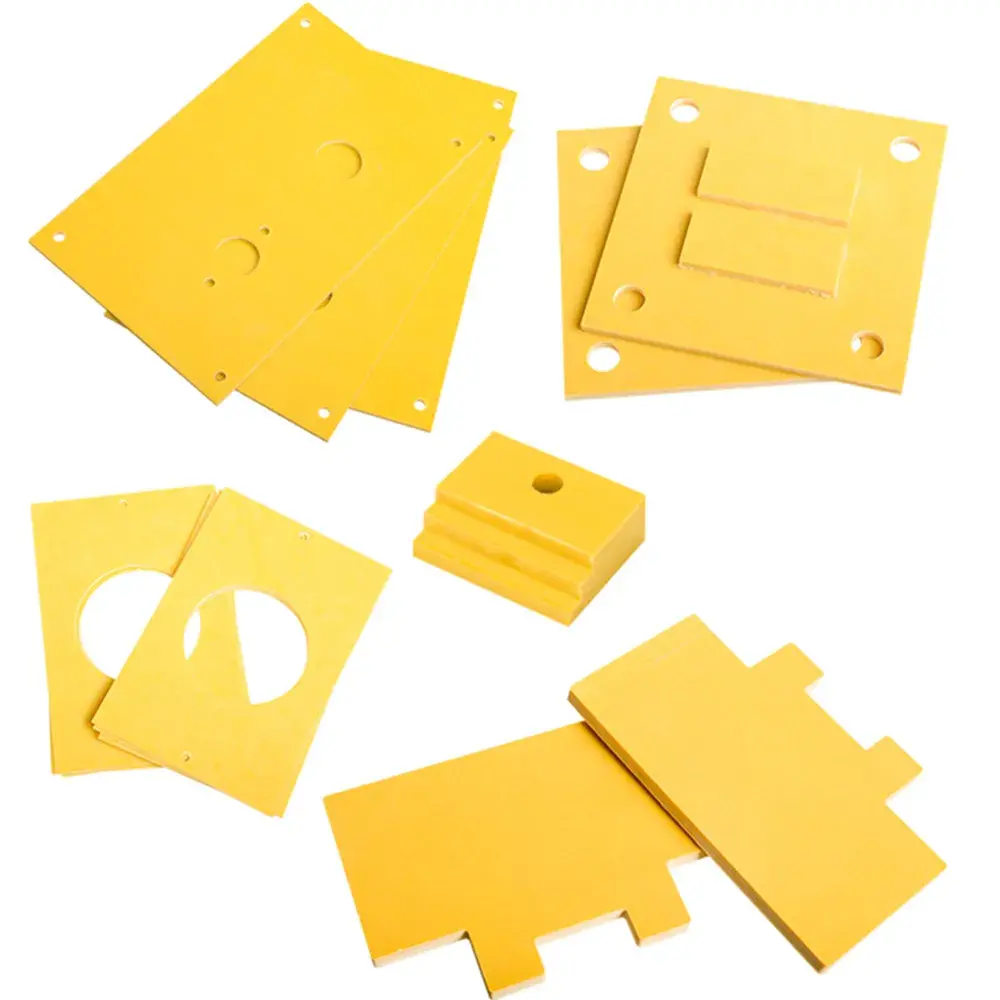

Are 3240 Epoxy Laminates Resistant to UV and Weathering?

UV Resistance of 3240 Epoxy Boards

3240 epoxy boards demonstrate commendable resistance to ultraviolet (UV) radiation, a critical factor for outdoor applications. The epoxy resin used in these boards contains UV stabilizers that help mitigate the degradative effects of prolonged sun exposure. These stabilizers work by absorbing harmful UV rays and dissipating them as heat, thereby protecting the polymer matrix from photodegradation. While no material is entirely immune to UV effects, 3240 epoxy boards maintain their mechanical and electrical properties for extended periods under normal outdoor conditions.

Weathering Performance of 3240 Laminates

The weathering performance of 3240 epoxy laminates is noteworthy. These boards exhibit excellent resistance to moisture, which is crucial for outdoor use. The epoxy resin forms a tight cross-linked structure that significantly reduces water absorption, preventing swelling and delamination. Furthermore, 3240 boards show good resistance to thermal cycling, maintaining dimensional stability across a wide temperature range. This characteristic is particularly valuable in environments with significant temperature fluctuations between day and night or across seasons.

Long-term Durability in Outdoor Environments

When considering long-term durability, 3240 epoxy boards prove their mettle. The combination of UV resistance and weather resilience contributes to an extended service life in outdoor settings. These boards resist cracking, chalking, and color fading, common issues with less durable materials exposed to the elements. However, it's important to note that extreme environmental conditions, such as prolonged exposure to saltwater spray or highly corrosive atmospheres, may necessitate additional protective measures to ensure optimal performance.

Mechanical and Electrical Properties Under Outdoor Exposure

Impact of Temperature Fluctuations on Mechanical Strength

3240 epoxy boards maintain impressive mechanical strength even when subjected to outdoor temperature variations. The glass transition temperature (Tg) of these boards is typically high, allowing them to retain their rigidity and load-bearing capabilities across a broad temperature range. Thermal expansion and contraction are minimal, reducing the risk of warping or stress-induced fractures. However, extreme temperature swings may slightly affect flexural and tensile strengths, necessitating consideration in design calculations for critical structural applications.

Moisture Effects on Electrical Insulation Properties

The electrical insulation properties of 3240 epoxy boards are paramount for many outdoor applications. These laminates exhibit excellent resistance to moisture ingress, which is crucial for maintaining their dielectric strength and surface resistivity. The low water absorption rate of epoxy resins helps prevent the formation of conductive paths within the material. Nevertheless, prolonged exposure to high humidity or direct water contact may gradually impact insulation resistance. Proper design considerations, such as the use of edge sealing or protective coatings, can further enhance the boards' electrical performance in moist environments.

Aging and Its Impact on Material Performance

Aging is an inevitable process for materials exposed to outdoor conditions, and 3240 epoxy boards are no exception. However, these laminates demonstrate remarkable resilience to age-related degradation. The cross-linked structure of the epoxy resin resists chemical breakdown, maintaining the board's structural integrity over time. While subtle changes in color or surface texture may occur, the core mechanical and electrical properties remain largely unaffected for many years. Regular inspections and preventive maintenance can help identify and address any signs of aging, ensuring continued optimal performance in long-term outdoor installations.

Outdoor Applications of 3240 in Power and Control Systems

Use in Outdoor Electrical Enclosures

3240 epoxy boards find extensive use in outdoor electrical enclosures, where they serve as insulating barriers and structural components. These enclosures house critical electrical equipment and must withstand various environmental challenges. The boards' excellent electrical insulation properties, combined with their moisture and UV resistance, make them ideal for this application. They provide reliable protection against electrical hazards while maintaining the integrity of the enclosure. In regions prone to extreme weather, 3240 boards contribute to the overall robustness of these installations, ensuring uninterrupted power distribution and control system operation.

Applications in Renewable Energy Systems

The renewable energy sector, particularly solar and wind power installations, leverages the benefits of 3240 epoxy boards. In solar panel mounting systems, these boards serve as insulating spacers and structural supports, withstanding the harsh conditions typical of solar farms. For wind turbines, 3240 laminates find use in various components, including nacelle insulation and control panel backplanes. The material's ability to resist moisture, UV radiation, and temperature fluctuations while maintaining excellent electrical properties makes it a preferred choice for these demanding outdoor applications in the renewable energy field.

Durability in Outdoor Control Panels and Switchgear

Outdoor control panels and switchgear are critical components in power distribution networks, often exposed to challenging environmental conditions. 3240 epoxy boards excel in these applications due to their combination of electrical insulation, mechanical strength, and weather resistance. They serve as mounting plates for electrical components, insulation barriers, and structural elements within these assemblies. The boards' dimensional stability ensures that sensitive alignments and clearances are maintained despite temperature variations. Their resistance to moisture and contaminants helps prevent tracking and electrical breakdown, contributing to the overall reliability and longevity of outdoor electrical infrastructure.

Conclusion

3240 epoxy boards have proven their mettle in outdoor applications, offering a unique combination of durability, electrical insulation, and weather resistance. Their ability to withstand UV radiation, moisture, and temperature fluctuations makes them invaluable in various exterior settings, from electrical enclosures to renewable energy systems. While these boards exhibit excellent outdoor performance, proper installation and periodic maintenance remain crucial for maximizing their longevity. As the demand for reliable materials in outdoor electrical and structural applications continues to grow, 3240 epoxy boards stand out as a versatile and dependable solution, capable of meeting the challenges posed by diverse environmental conditions.

Contact Us

For more information about our 3240 epoxy boards and their outdoor applications, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your outdoor insulation needs.