The Composition and Properties of G10 Fiberglass Sheet

Material Composition and Manufacturing Process

G10 fiberglass sheet is a composite material crafted from epoxy resin and woven glass fabric. The manufacturing process involves layering multiple sheets of glass fabric and impregnating them with epoxy resin under high pressure and temperature. This meticulous process results in a dense, homogeneous material with superior electrical and mechanical properties.

Electrical Insulation Characteristics

One of the paramount features of G10 fiberglass sheet is its exceptional electrical insulation capabilities. The material boasts a high dielectric strength, low dielectric constant, and minimal electrical losses. These properties make G10 fiberglass sheet an exemplary choice for transformer applications where maintaining electrical isolation is crucial.

Mechanical and Thermal Properties

Beyond its electrical prowess, G10 fiberglass sheet exhibits remarkable mechanical strength and thermal stability. It maintains its structural integrity across a wide temperature range, resists deformation under load, and demonstrates excellent durability. These attributes contribute significantly to the overall reliability and longevity of transformer components.

Applications of G10 Fiberglass Sheet in Transformer Design

Insulation Components

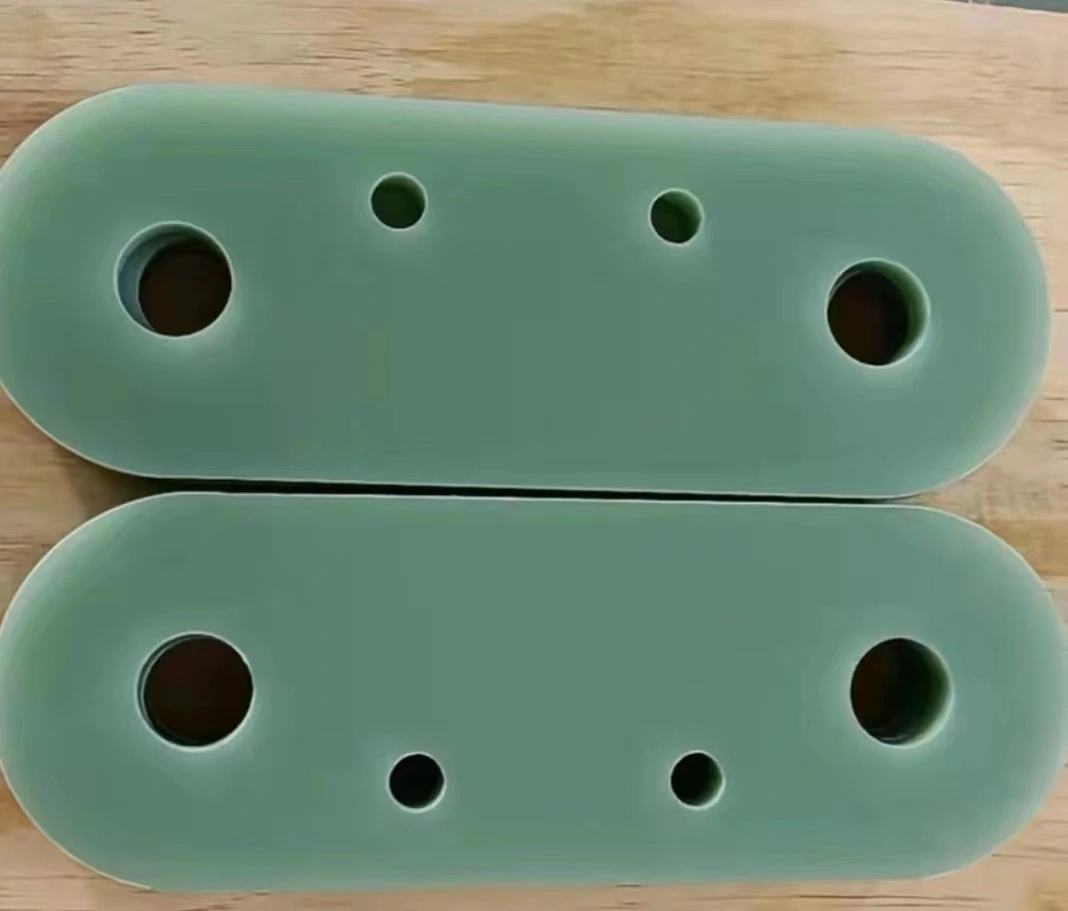

G10 fiberglass sheet finds extensive use in various insulation components within transformers. It serves as an effective barrier between conductive parts, preventing electrical arcing and short circuits. Common applications include insulating spacers, barriers, and supports that maintain critical clearances between energized components.

Structural Elements

The robust mechanical properties of G10 fiberglass sheet make it an excellent material for structural elements within transformers. It is often utilized in the fabrication of coil forms, end frames, and support structures. These components benefit from the material's high strength-to-weight ratio and dimensional stability, ensuring reliable performance under various operating conditions.

Thermal Management

G10 fiberglass sheet plays a crucial role in thermal management within transformers. Its low thermal conductivity helps to contain and direct heat flow, preventing localized hot spots and promoting more efficient cooling. This aspect is particularly important in maintaining the overall efficiency and lifespan of the transformer.

Safety Enhancements Provided by G10 Fiberglass Sheet

Electrical Breakdown Prevention

The superior dielectric strength of G10 fiberglass sheet significantly reduces the risk of electrical breakdown within transformers. By providing a robust insulation barrier between high-voltage components, it mitigates the potential for arcing and short circuits, enhancing overall operational safety.

Fire Resistance Properties

G10 fiberglass sheet exhibits inherent flame-retardant properties, contributing to improved fire safety in transformer applications. Its ability to self-extinguish and resist flame propagation helps contain potential fire hazards, thereby reducing the risk of catastrophic failures and associated safety concerns.

Environmental Stability

The exceptional chemical resistance and moisture absorption properties of G10 fiberglass sheet ensure its stability in various environmental conditions. This stability translates to consistent performance and reduced degradation over time, enhancing the overall safety and reliability of transformer systems in diverse operating environments.

Efficiency Improvements Facilitated by G10 Fiberglass Sheet

Reduction of Electrical Losses

G10 fiberglass sheet's low dielectric losses contribute significantly to the overall efficiency of transformers. By minimizing energy dissipation in the insulation system, it helps to reduce heat generation and improve the transformer's power transfer efficiency. This reduction in electrical losses translates to lower operating costs and improved energy conservation.

Enhanced Thermal Management

The thermal properties of G10 fiberglass sheet play a crucial role in maintaining optimal operating temperatures within transformers. Its low thermal conductivity helps to contain and direct heat flow, preventing localized hot spots and promoting more efficient cooling. This improved thermal management leads to reduced energy consumption for cooling systems and extends the operational life of transformer components.

Longevity and Reliability

The durability and stability of G10 fiberglass sheet contribute to the longevity and reliability of transformer systems. By maintaining its electrical and mechanical properties over extended periods, even under challenging conditions, G10 fiberglass sheet reduces the need for frequent maintenance and replacements. This increased reliability translates to improved operational efficiency and reduced downtime for transformer systems.

Comparative Analysis: G10 Fiberglass Sheet vs. Alternative Materials

Electrical Performance Comparison

When compared to alternative insulating materials, G10 fiberglass sheet often demonstrates superior electrical performance. Its high dielectric strength and low dielectric constant outperform many traditional insulation materials, such as phenolic resins or certain plastics. This enhanced electrical performance allows for more compact transformer designs without compromising safety or efficiency.

Mechanical Strength and Durability

G10 fiberglass sheet exhibits exceptional mechanical strength and durability compared to many alternative materials. Its high tensile and compressive strength, coupled with excellent dimensional stability, make it a preferred choice for structural components in transformers. This superior mechanical performance contributes to the overall robustness and longevity of transformer systems.

Cost-Effectiveness and Long-Term Value

While the initial cost of G10 fiberglass sheet may be higher than some alternative materials, its long-term value proposition is often superior. The material's durability, stability, and performance characteristics contribute to reduced maintenance requirements and extended service life. When considering the total cost of ownership over the lifespan of a transformer, G10 fiberglass sheet frequently emerges as a cost-effective solution.

Future Trends and Innovations in G10 Fiberglass Sheet Technology

Advancements in Material Composition

Ongoing research in material science is leading to advancements in the composition of G10 fiberglass sheet. Emerging trends include the development of nano-composite variants that offer enhanced electrical and thermal properties. These innovations promise to further improve the performance and efficiency of transformers in the future.

Smart Insulation Systems

The integration of sensor technologies with G10 fiberglass sheet is an emerging trend in transformer design. These smart insulation systems can provide real-time monitoring of electrical and thermal conditions, enabling predictive maintenance and optimized performance. This integration of digital technologies with traditional insulation materials represents a significant step towards more intelligent and efficient transformer systems.

Sustainability and Environmental Considerations

As environmental concerns gain prominence, the focus on sustainable materials in transformer design is increasing. Future developments in G10 fiberglass sheet technology are likely to emphasize eco-friendly manufacturing processes and improved recyclability. These advancements will contribute to reducing the environmental impact of transformer systems while maintaining high performance standards.

Conclusion

G10 fiberglass sheet has proven to be an invaluable material in enhancing the safety and efficiency of transformer systems. Its exceptional electrical insulation properties, combined with robust mechanical characteristics, make it an ideal choice for various critical components within transformers. By preventing electrical breakdown, improving thermal management, and ensuring long-term reliability, G10 fiberglass sheet contributes significantly to the overall performance and longevity of transformer systems. As technology continues to advance, the role of G10 fiberglass sheet in transformer design is likely to evolve, promising even greater improvements in safety, efficiency, and sustainability for future power distribution systems.

Contact Us

For more information about our G10 fiberglass sheet products and how they can enhance your transformer applications, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the optimal solution for your specific needs.