Properties and Characteristics of G10 Fiberglass Sheets

Composition and Manufacturing Process

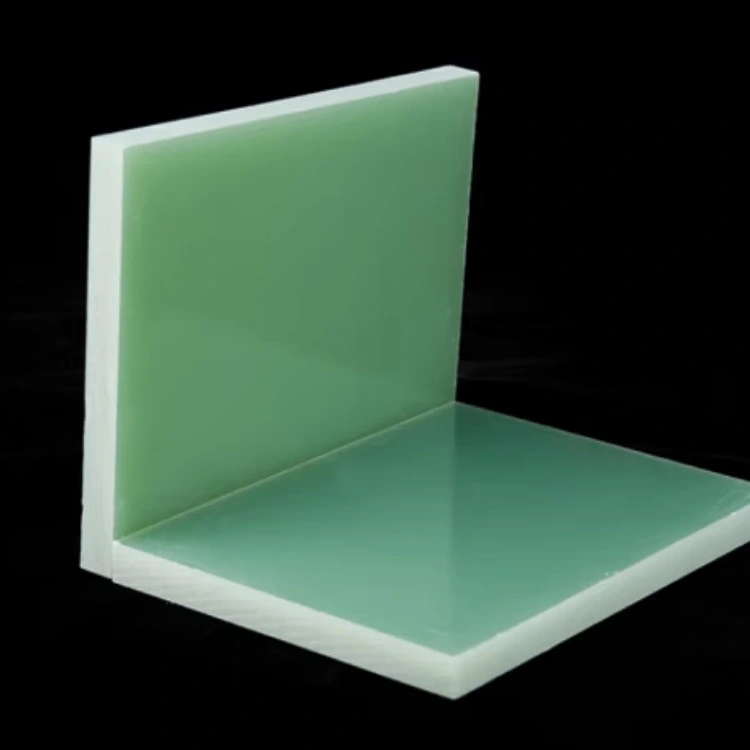

G10 fiberglass sheets are manufactured by combining woven glass fiber fabric with high-grade epoxy resin to create a strong composite material. During production, layers of glass fabric are thoroughly impregnated with epoxy resin under precise temperature and pressure conditions, ensuring full saturation and adhesion. The stack is then cured to polymerize the resin, resulting in a rigid, dense, and homogeneous laminate. This process produces sheets with excellent bond strength, moisture resistance, and consistent quality, making them highly reliable for electrical and mechanical applications.

Electrical Insulation Properties

G10 fiberglass sheets are prized for their outstanding electrical insulation characteristics, essential in dry-type transformer design. They possess high dielectric strength, effectively preventing electrical breakdown even under elevated voltages. Their low dielectric constant minimizes energy loss, while excellent arc resistance ensures durability against electrical discharges. These properties allow G10 sheets to insulate transformer windings, terminals, and structural components safely. Their reliable performance under electrical stress conditions reduces the risk of short circuits or insulation failure, enhancing transformer operational safety and longevity in demanding environments.

Mechanical Strength and Dimensional Stability

G10 fiberglass sheets exhibit superior mechanical properties critical for transformer structural integrity. They have high tensile, compressive, and flexural strength, enabling them to endure mechanical loads, vibrations, and physical stress without deformation. Additionally, their dimensional stability remains consistent across a broad temperature range, preventing warping or expansion that could compromise component alignment. This combination of strength and stability ensures G10 sheets provide reliable mechanical support and electrical insulation in transformer assemblies, contributing to the durability and efficient operation of dry-type transformers in power distribution systems.

Specific Applications in Dry-Type Transformers

Coil Formers and Insulating Cylinders

G10 fiberglass sheets are extensively utilized to manufacture coil formers and insulating cylinders in dry-type transformers. These components serve as sturdy, stable platforms for winding transformer coils, ensuring that the coils maintain their shape and spacing throughout operation. The exceptional mechanical strength of G10 allows for precise machining into complex shapes required by custom transformer designs. Additionally, G10’s excellent electrical insulation properties help prevent short circuits and maintain safe electrical isolation between the coils and the transformer core.

End Flanges and Spacers

End flanges and spacers fabricated from G10 fiberglass sheets play a vital role in preserving the structural integrity of transformer windings. These parts secure the coils in place, preventing deformation or displacement caused by mechanical stresses and thermal expansion during transformer operation. The dimensional stability of G10 ensures that these components retain their shape and insulating properties over time, even under harsh environmental conditions, thereby contributing to the longevity and reliable performance of the transformer.

Barriers and Insulating Boards

G10 fiberglass sheets are widely employed as barriers and insulating boards inside dry-type transformers to separate various voltage zones and prevent electrical flashovers. Thanks to their excellent dielectric strength and machinability, these sheets can be custom-cut and shaped to accommodate intricate transformer designs and confined spaces. This adaptability ensures effective insulation around complex components, reducing the risk of electrical faults and enhancing the overall safety and efficiency of the transformer throughout its service life.

Benefits of Using G10 Fiberglass Sheets in Dry-Type Transformers

Enhanced Thermal Management

G10 fiberglass sheets possess outstanding thermal properties, including low coefficients of thermal expansion and excellent heat resistance. These qualities enable effective heat dissipation within dry-type transformers, helping to keep internal temperatures stable during continuous operation. By minimizing thermal deformation or warping, G10 sheets maintain the integrity of the insulation system, preventing damage caused by overheating. This enhanced thermal management supports the efficient functioning and safety of transformers, even under demanding electrical loads and fluctuating environmental conditions.

Increased Reliability and Lifespan

Incorporating G10 fiberglass sheets into dry-type transformers greatly improves their reliability and extends service life. The sheets’ high mechanical strength and electrical insulation prevent failures caused by mechanical stress, vibration, or electrical breakdown. Their durability under varying temperatures and operational stresses reduces maintenance frequency and downtime. Consequently, transformers built with G10 materials demonstrate lower lifecycle costs, higher operational efficiency, and better overall performance, providing long-term value for utilities and industrial users.

Environmental Resistance and Safety

G10 fiberglass sheets offer superior resistance to environmental challenges such as moisture ingress, chemical exposure, and ultraviolet radiation. These protective qualities safeguard transformer components from premature aging and degradation in harsh industrial or outdoor settings. Furthermore, G10’s inherent flame-retardant properties reduce fire risk during electrical faults or overheating events. This combination of chemical resistance and fire safety enhances transformer installation safety, contributing to regulatory compliance and reducing hazards for personnel and surrounding equipment.

Conclusion

The application of G10 fiberglass sheets in dry-type transformers exemplifies the synergy between advanced materials science and electrical engineering. These versatile composite sheets provide a unique combination of electrical insulation, mechanical strength, and thermal stability, making them indispensable in modern transformer design. By enhancing efficiency, reliability, and safety, G10 fiberglass sheets contribute significantly to the performance and longevity of dry-type transformers across various industries and power distribution applications. As the demand for more efficient and reliable electrical infrastructure continues to grow, the role of G10 fiberglass sheets in transformer technology is likely to expand, driving further innovations in this critical field.

Contact Us

For more information about our G10 fiberglass sheets and their applications in dry-type transformers, please contact our expert team at info@jhd-material.com. Our specialists are ready to assist you in finding the optimal insulating solutions for your transformer projects.