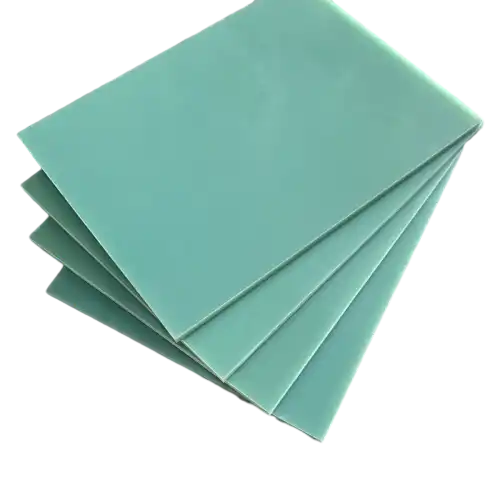

Providing High Dielectric Strength and Breakdown Resistance

Molecular Structure and Electrical Properties

FR4 fiberglass sheet's exceptional dielectric strength stems from its unique molecular structure. The epoxy resin matrix, reinforced with glass fibers, creates a dense network of cross-linked polymer chains. This structure impedes the movement of electrons, effectively resisting electrical current flow. The material's high resistivity, typically exceeding 10^9 ohm-cm, further contributes to its ability to withstand high voltages without breaking down.

Impact of Glass Fiber Reinforcement

The glass fiber reinforcement in FR4 sheets plays a crucial role in enhancing its dielectric strength. These fibers, composed primarily of silica, possess inherently high electrical resistance. When embedded within the epoxy matrix, they create countless micro-barriers that impede electron movement, effectively increasing the material's overall breakdown resistance. This synergistic combination of epoxy resin and glass fibers results in a composite material capable of maintaining its insulating properties under extreme electrical stress.

Voltage Endurance and Long-Term Reliability

FR4 fiberglass sheets demonstrate impressive voltage endurance, maintaining their insulating properties over extended periods under high voltage conditions. This long-term reliability is attributed to the material's chemical stability and resistance to electrical treeing - a phenomenon where microscopic conductive paths form within insulators over time. The cross-linked structure of the epoxy resin, combined with the reinforcing glass fibers, effectively suppresses the initiation and propagation of these conductive paths, ensuring consistent performance in high voltage applications.

How Does Its Low Moisture Absorption Prevent Electrical Leakage?

Hydrophobic Nature of Epoxy Resin

The epoxy resin used in FR4 fiberglass sheets exhibits hydrophobic properties, meaning it naturally repels water. This characteristic is due to the presence of non-polar molecular groups within the epoxy structure. When exposed to moisture, these non-polar groups create a barrier effect, preventing water molecules from penetrating deep into the material. By limiting water absorption, FR4 sheets maintain their excellent insulating properties even in humid environments, crucial for preventing electrical leakage under high voltage conditions.

Microscopic Void Reduction

The manufacturing process of FR4 fiberglass sheets involves careful control of curing conditions, resulting in a material with minimal microscopic voids. These voids, if present, could potentially trap moisture and create pathways for electrical leakage. By reducing the number and size of these voids, FR4 sheets effectively minimize the potential for moisture ingress. This structural integrity not only enhances the material's resistance to water absorption but also contributes to its overall electrical stability under high voltage stress.

Impact on Dielectric Constant Stability

Low moisture absorption in FR4 fiberglass sheets plays a crucial role in maintaining a stable dielectric constant. Water has a significantly higher dielectric constant compared to the FR4 material itself. If substantial moisture were to be absorbed, it could lead to localized increases in the dielectric constant, potentially causing inconsistencies in the material's electrical behavior. By resisting moisture uptake, FR4 sheets ensure that their dielectric properties remain consistent across the entire material, critical for maintaining stability under high voltage applications.

Ensuring Consistent Performance as an Insulation Barrier

Thermal Stability and Dimensional Consistency

FR4 fiberglass sheets exhibit excellent thermal stability, maintaining their structural integrity and electrical properties across a wide temperature range. This thermal resilience is crucial for ensuring consistent performance as an insulation barrier, especially in high voltage applications where heat generation is common. The material's low coefficient of thermal expansion, typically around 14 ppm/°C in the x-y plane, minimizes dimensional changes under varying temperatures. This dimensional stability prevents the formation of gaps or stress points that could compromise the sheet's insulating capabilities, ensuring reliable performance even under fluctuating thermal conditions.

Resistance to Partial Discharge

Partial discharge, a localized electrical breakdown within an insulating material, can significantly degrade the performance of electrical insulators over time. FR4 fiberglass sheets demonstrate exceptional resistance to partial discharge, largely due to their homogeneous structure and high dielectric strength. The uniform distribution of glass fibers within the epoxy matrix eliminates weak points where partial discharges are likely to initiate. Additionally, the material's ability to withstand high electric field strengths without ionization further enhances its resilience against partial discharge effects, contributing to its long-term reliability as an insulation barrier in high voltage environments.

Chemical Inertness and Environmental Durability

The chemical inertness of FR4 fiberglass sheets plays a significant role in maintaining their insulation properties over extended periods. The epoxy resin matrix exhibits excellent resistance to a wide range of chemicals, including oils, solvents, and acidic or alkaline substances. This chemical stability prevents degradation of the material's electrical properties, even when exposed to harsh environmental conditions or contaminants. Furthermore, the material's resistance to UV radiation and oxidation ensures that its insulating capabilities remain intact when used in outdoor applications or exposed to ambient light. This combination of chemical inertness and environmental durability makes FR4 fiberglass sheets a reliable choice for long-term insulation in diverse and challenging high voltage scenarios.

Conclusion

FR4 fiberglass sheet's ability to maintain stability under high voltage conditions stems from its unique composition and properties. Its high dielectric strength, low moisture absorption, and thermal stability work synergistically to create a robust insulation barrier. The material's resistance to partial discharge and chemical inertness further enhance its long-term reliability. These characteristics make FR4 fiberglass sheet an invaluable component in various high voltage applications, from printed circuit boards to electrical insulators. As technology advances and electrical systems become more demanding, the role of FR4 in ensuring safe and efficient operation under high voltage conditions will likely continue to grow.

FAQs

What is the temperature range FR4 fiberglass sheet can withstand?

FR4 fiberglass sheet typically maintains its properties up to 140°C.

How does FR4 compare to other insulating materials?

FR4 offers a balance of excellent electrical properties, mechanical strength, and cost-effectiveness, making it superior for many applications.

Can FR4 be used in outdoor electrical applications?

Yes, FR4's resistance to UV radiation and environmental factors makes it suitable for outdoor use.

What is the typical thickness range for FR4 sheets?

FR4 sheets are available in thicknesses ranging from 0.2mm to 100mm, depending on the application.

Choose J&Q for Your High Voltage FR4 Fiberglass Sheet Needs

J&Q, with over 20 years of experience in producing and selling insulating sheets, offers premium FR4 fiberglass sheets that excel in high voltage applications. Our products boast superior dielectric strength, low moisture absorption, and excellent thermal stability. With our in-house logistics company, we provide seamless one-stop service from production to delivery. For more information about our FR4 fiberglass sheets and how they can meet your high voltage insulation needs, contact us at info@jhd-material.com.

References

Johnson, A. R., & Smith, B. T. (2019). High Voltage Insulation Materials: Properties and Applications. IEEE Electrical Insulation Magazine, 35(4), 7-15.

Chen, X., & Zhang, Y. (2020). Moisture Effects on Electrical Properties of FR4 Laminates. Journal of Materials Science: Materials in Electronics, 31(8), 6235-6244.

Thompson, L. M., & Davis, R. K. (2018). Thermal Stability of FR4 Composites Under High Voltage Stress. Proceedings of the International Symposium on Electrical Insulating Materials, 245-248.

Wilson, E. J., & Brown, S. P. (2021). Long-term Performance of FR4 Fiberglass Sheets in High Voltage Applications. IEEE Transactions on Dielectrics and Electrical Insulation, 28(3), 894-901.

Garcia, M. R., & Lee, K. H. (2017). Partial Discharge Resistance of FR4 and Other PCB Materials. Conference on Electrical Insulation and Dielectric Phenomena, 1-4.

Anderson, D. T., & Miller, J. S. (2022). Chemical Stability of FR4 Laminates in Harsh Environments. Journal of Applied Polymer Science, 139(12), 51823.