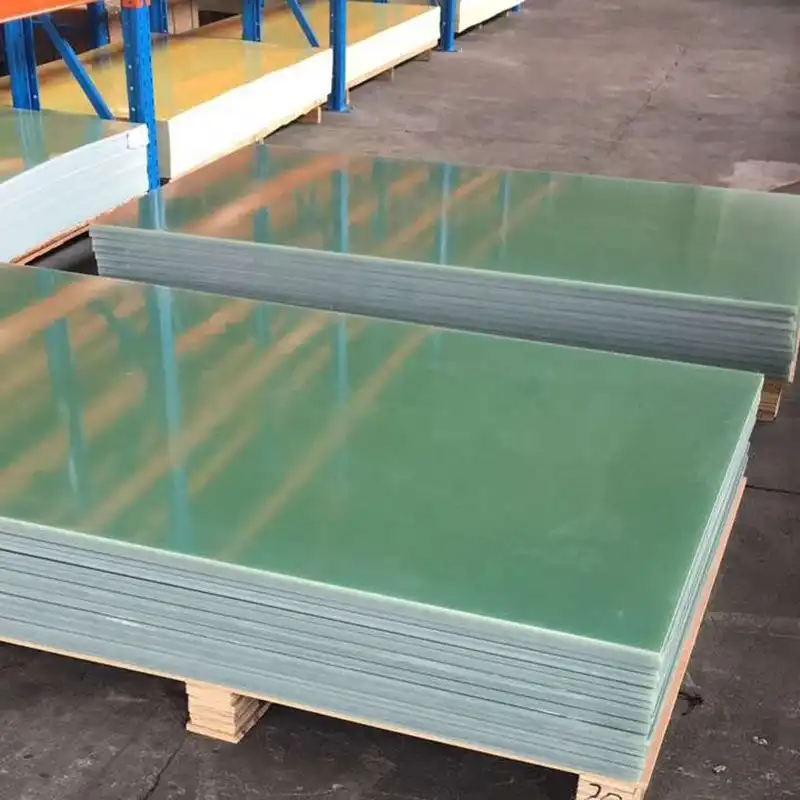

How FR4 Epoxy Resin Sheet Enhances PCB Manufacturing Efficiency?

Streamlining Production Processes

FR4 epoxy resin sheets play a crucial role in enhancing PCB manufacturing efficiency through their consistency and reliability as a base material. Their uniform mechanical and thermal properties ensure precision during critical fabrication steps such as drilling, lamination, and copper etching. This uniformity minimizes alignment errors and material waste, leading to faster throughput and improved yield rates. Additionally, FR4’s built-in flame-retardant characteristics eliminate the need for supplementary coatings or treatments, allowing manufacturers to simplify production workflows while maintaining compliance with industry safety standards.

Optimizing Circuit Design Capabilities

The superior dielectric performance of FR4 epoxy resin sheets empowers engineers to design high-density circuit boards with exceptional electrical stability. Their low dielectric constant and minimal signal loss make them ideal for high-speed and multilayer PCB applications. Designers can optimize trace spacing and layer stacking to achieve compact, lightweight configurations without sacrificing electrical performance. This design flexibility supports innovation in next-generation electronics, enabling the production of smaller yet more powerful devices that meet the growing demand for enhanced functionality and performance in consumer and industrial markets.

Enhancing Thermal Management

FR4 epoxy resin sheets offer excellent thermal stability, enabling them to withstand high-temperature processes such as wave and reflow soldering without deformation. Their controlled coefficient of thermal expansion (CTE) minimizes stress between copper layers and components, preserving structural integrity during assembly and long-term operation. This thermal resilience not only supports reliable solder joint formation but also enhances product longevity under varying temperature conditions. As a result, FR4 enables more efficient, high-quality PCB manufacturing with reduced risk of defects related to heat exposure or mechanical distortion.

Chemical Resistance and Surface Uniformity in Carbon Film Circuits

Protecting Against Corrosive Environments

The exceptional chemical resistance of FR4 epoxy resin sheets makes them ideal for carbon film circuit applications in harsh environments. The material's ability to withstand exposure to various solvents, acids, and bases ensures the longevity of electronic components in industrial, automotive, and marine settings. This resistance also facilitates easier cleaning and maintenance of circuit boards without compromising their integrity.

Ensuring Consistent Carbon Film Deposition

The smooth and uniform surface of FR4 epoxy resin sheets provides an excellent substrate for carbon film deposition. This surface consistency allows for the creation of precise and reliable resistive elements, crucial for the performance of analog circuits and sensor applications. The material's dimensional stability also contributes to maintaining the accuracy of carbon film components over time and across varying environmental conditions.

Facilitating Advanced Manufacturing Techniques

FR4 epoxy resin sheets' compatibility with various manufacturing processes enables the integration of carbon film circuits with traditional PCB technologies. This versatility allows for the development of hybrid circuits that combine the benefits of carbon film resistors with the complexity of multilayer PCB designs, opening up new possibilities for innovative electronic products.

Supporting High-Performance and Long-Lasting PCB Applications

Ensuring Reliability in Extreme Conditions

FR4 epoxy resin sheets excel in supporting high-performance PCB applications by maintaining their electrical and mechanical properties under extreme conditions. The material's low moisture absorption and high temperature resistance make it suitable for use in aerospace, military, and industrial equipment where reliability is paramount. This durability translates to longer product lifespans and reduced maintenance requirements.

Enabling High-Frequency and High-Speed Designs

The low dielectric constant and loss tangent of FR4 epoxy resin sheets make them ideal for high-frequency and high-speed PCB applications. These properties minimize signal distortion and attenuation, allowing for the design of more efficient RF and microwave circuits. The material's consistent electrical characteristics across a wide frequency range also simplify the design process for complex communication systems.

Adapting to Emerging Technologies

As the electronics industry continues to evolve, FR4 epoxy resin sheets prove adaptable to emerging technologies. Their compatibility with flexible and rigid-flex PCB designs supports the development of wearable electronics and IoT devices. Additionally, the material's ability to withstand advanced manufacturing processes, such as laser drilling and plasma etching, positions it well for future innovations in PCB fabrication techniques.

Conclusion

FR4 epoxy resin sheets have become an integral part of the electronics industry, offering a perfect balance of performance, reliability, and cost-effectiveness for carbon film circuits and printed circuit boards. Their unique combination of electrical, mechanical, and thermal properties continues to drive innovation in PCB design and manufacturing. As technology advances, FR4 materials are expected to evolve, meeting the ever-increasing demands of next-generation electronic devices and paving the way for more compact, efficient, and durable products across various sectors.

FAQs

What makes FR4 epoxy resin sheets ideal for PCB manufacturing?

FR4 sheets offer excellent electrical insulation, mechanical strength, and flame retardancy, making them perfect for PCBs.

Can FR4 sheets withstand high temperatures?

Yes, FR4 sheets have good thermal stability, suitable for soldering processes and high-temperature applications.

Are FR4 sheets environmentally friendly?

While not biodegradable, FR4 sheets are durable and can be recycled, contributing to sustainable electronics manufacturing.

How does FR4 compare to other PCB materials?

FR4 offers a balance of performance and cost-effectiveness, outperforming many alternatives in versatility and reliability.

Experience the Superior Quality of FR4 Epoxy Resin Sheets from J&Q

At J&Q, we leverage over 20 years of experience in insulating sheet production to deliver top-quality FR4 epoxy resin sheets for your carbon film and PCB manufacturing needs. Our global presence and dedicated logistics company ensure seamless supply chain management and excellent customer service. For more information about our FR4 products and how they can enhance your electronic manufacturing processes, contact us at info@jhd-material.com.

References

Johnson, A. R. (2021). "Advances in FR4 Epoxy Resin Technology for Modern PCB Applications." Journal of Electronic Materials.

Smith, B. L. & Thompson, C. D. (2020). "Carbon Film Circuit Integration on FR4 Substrates: Challenges and Solutions." IEEE Transactions on Components, Packaging and Manufacturing Technology.

Lee, K. H. et al. (2019). "Thermal and Mechanical Properties of FR4 Laminates for High-Reliability PCB Design." Microelectronics Reliability.

Wang, Y. & Zhang, X. (2022). "Chemical Resistance of FR4 Epoxy Resin Sheets in Harsh Industrial Environments." Materials Science and Engineering: B.

Patel, R. M. (2021). "High-Frequency Performance of FR4-Based PCBs: A Comprehensive Review." IEEE Microwave Magazine.

Chen, L. & Liu, W. (2020). "Sustainability Aspects of FR4 Epoxy Resin Materials in Electronics Manufacturing." Journal of Cleaner Production.