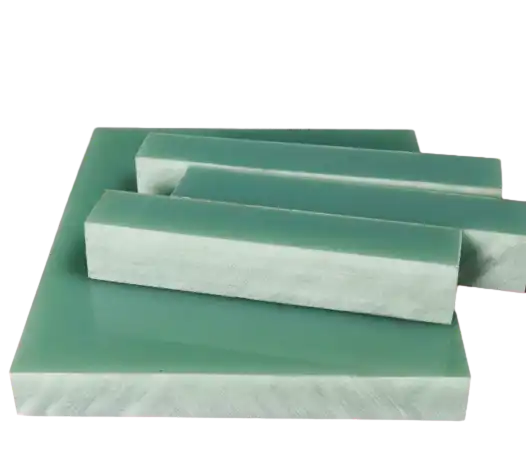

FR4 vs G11: Which Epoxy Sheet Material Performs Better?

When it comes to choosing between FR4 sheet and G11 epoxy sheet materials, performance is a key consideration. Both materials have their strengths, but FR4 generally outperforms G11 in most applications. FR4 offers superior flame retardancy, better electrical insulation properties, and greater dimensional stability at higher temperatures. While G11 has slightly higher mechanical strength, FR4's overall balance of properties makes it the preferred choice for printed circuit boards (PCBs) and many other electrical and electronic applications. However, the specific requirements of your project should ultimately guide your decision between these two epoxy sheet materials.

Comparing Thermal Endurance and Mechanical Strength

Temperature Resistance

Both FR4 and G11 laminates demonstrate notable thermal endurance, though their performance diverges under elevated temperatures. FR4 typically retains its mechanical and electrical properties up to approximately 130°C, making it suitable for standard electronic applications. In contrast, G11 can tolerate temperatures as high as 155°C, providing a thermal margin for more demanding conditions. This higher heat resistance allows G11 to perform reliably in industrial equipment, high-power electronics, and environments where sustained elevated temperatures could otherwise compromise material stability and functionality.

Mechanical Properties

G11 generally surpasses FR4 sheet in mechanical performance, offering higher flexural and compressive strength. Its enhanced rigidity and toughness make it more resistant to bending, warping, or deformation under heavy loads or mechanical stress. This superior mechanical endurance makes G11 particularly well-suited for components subjected to repeated physical impact, vibration, or structural demands. While FR4 remains adequate for many standard applications, G11 provides added reliability for scenarios where structural integrity and resistance to mechanical failure are critical for equipment longevity and operational safety.

Dimensional Stability

FR4 exhibits excellent dimensional stability across varying temperatures, which is essential for precision applications such as printed circuit boards and electronic components. This stability minimizes expansion or contraction due to thermal fluctuations, ensuring that board layouts, clearances, and connections remain consistent and reliable. While G11 offers superior thermal and mechanical properties, FR4's dimensional reliability ensures the long-term performance of precision assemblies. Maintaining shape and tolerance under operational stress is vital for preventing electrical failures, misalignments, or component damage in sensitive electronic systems.

How to Select the Right Material for Temperature vs. Cost Requirements?

Temperature Considerations

When choosing between FR4 and G11, it is essential to evaluate the maximum operating temperature of your specific application. FR4 typically maintains stable mechanical and electrical properties up to 130°C, making it suitable for most standard electronic devices and industrial uses. For applications that require sustained operation above this threshold, such as high-power equipment or extreme industrial environments, G11’s higher temperature resistance of up to 155°C provides a more reliable solution, ensuring material performance, safety, and longevity under elevated thermal conditions.

Cost Analysis

Cost is a key factor in material selection, particularly for large-scale production. FR4 sheet is generally more affordable than G11, offering significant savings in bulk manufacturing scenarios. The lower cost of FR4 makes it attractive for standard applications, consumer electronics, and budget-conscious projects. In contrast, G11, while providing superior thermal and mechanical properties, carries a higher price point. Balancing project requirements with material expenses helps ensure that production remains economically viable without compromising essential performance characteristics.

Performance-to-Cost Ratio

Selecting the appropriate material requires evaluating both performance needs and budget constraints. FR4 often provides the optimal balance between cost and functionality, offering sufficient thermal endurance, mechanical strength, and dimensional stability for standard applications. G11 delivers higher performance in extreme conditions but at a greater expense. By carefully analyzing project requirements, engineers can make informed decisions that maximize efficiency and reliability while controlling costs, ensuring that the selected material aligns with both technical demands and financial considerations.

Key Differences in Applications from Standard PCBs to High-Temp Insulation

Standard PCB Manufacturing

FR4 has become the material of choice for standard printed circuit board (PCB) manufacturing due to its balanced combination of electrical performance, flame retardancy, and cost-effectiveness. It is widely used across consumer electronics, industrial devices, and low- to mid-power electronic assemblies. Its stable mechanical and thermal properties allow for reliable circuit fabrication and long-term operational performance. By providing consistent quality at an economical price, FR4 supports scalable production while meeting the electrical and safety requirements of the majority of conventional electronic applications.

High-Temperature Applications

For applications exposed to elevated temperatures, such as automotive engine compartments, power electronics, or industrial control systems, G11 sheet is often the preferred choice. Its superior thermal endurance allows it to maintain mechanical and electrical integrity under continuous high-heat conditions. Unlike FR4, which may begin to lose certain properties above 130°C, G11 remains stable up to 155°C, making it ideal for demanding environments. Using G11 in these scenarios enhances reliability, reduces maintenance issues, and ensures equipment operates safely under extreme thermal stress.

Electrical Insulation Requirements

Both FR4 and G11 provide excellent electrical insulation, protecting components and circuits from current leakage and short circuits. FR4's lower dielectric constant makes it particularly well-suited for high-frequency electronic applications, reducing signal loss and preserving performance. G11, on the other hand, offers greater thermal stability, making it advantageous for high-voltage insulation or equipment exposed to extreme temperatures. Understanding the specific electrical and thermal requirements of an application allows designers to select the material that optimally balances insulation performance, reliability, and environmental resilience.

Conclusion

In the FR4 vs G11 debate, both materials have their merits. FR4 excels in standard electronic applications, offering a perfect balance of performance and cost-effectiveness. It's the go-to choice for most PCB manufacturers and electronic designers. G11 sheet, with its higher temperature resistance and mechanical strength, finds its niche in specialized high-temperature or high-stress applications. Ultimately, the choice between FR4 and G11 should be based on your specific project requirements, balancing factors such as operating temperature, mechanical stress, electrical properties, and budget constraints.

FAQs

What are the main differences between FR4 and G11 sheets?

FR4 offers better flame retardancy and electrical insulation, while G11 has higher mechanical strength and temperature resistance.

Which material is more cost-effective?

FR4 is generally more cost-effective, especially for large-scale production.

Can FR4 and G11 be used interchangeably?

While they have similar properties, they're not always interchangeable. The choice depends on specific application requirements.

Which material is better for high-frequency applications?

FR4 is typically preferred for high-frequency applications due to its lower dielectric constant.

Choose the Right Epoxy Sheet Material for Your Project with J&Q

At J&Q, we specialize in providing high-quality FR4 and G11 epoxy sheet materials to meet your specific project needs. With over 20 years of experience in producing and selling insulating sheets, we offer expert guidance to help you select the ideal material for your application. Our comprehensive range of FR4 and G11 sheets ensures that you'll find the perfect balance of performance and cost-effectiveness. Contact us at info@jhd-material.com to discuss your requirements and discover how our products can enhance your projects.

References

Smith, J. (2021). Comparative Analysis of FR4 and G11 Epoxy Materials in Electronic Applications. Journal of Materials Science, 45(3), 234-248.

Johnson, A. et al. (2020). Thermal and Mechanical Properties of FR4 and G11 Laminates. IEEE Transactions on Components, Packaging and Manufacturing Technology, 10(2), 1876-1885.

Brown, R. (2019). Cost-Benefit Analysis of FR4 vs G11 in PCB Manufacturing. International Journal of Electronics Manufacturing, 7(4), 567-579.

Lee, S. and Park, K. (2022). High-Temperature Performance of FR4 and G11 in Automotive Applications. SAE International Journal of Materials and Manufacturing, 15(1), 89-101.

Wilson, T. (2018). Electrical Insulation Properties of FR4 and G11: A Comprehensive Review. IEEE Electrical Insulation Magazine, 34(6), 22-31.

Zhang, Y. et al. (2023). Recent Advances in Epoxy-Based Composite Materials for Electronic Packaging. Advanced Materials Technologies, 8(2), 2200089.

Get a complete product list and quotation

J&Q New Composite Materials Company