How Fiber Orientation Affects G10 Sheet CNC Machining?

How well G10 sheet CNC machining works is greatly affected by the direction of the fibers, which affects cutting forces, tool wear patterns, and the quality of the surface finish. The way the fiberglass support is arranged in the epoxy resin matrix gives it uneven qualities that change how easy it is to cut in different directions. When the direction of the fibers is parallel to the cutting forces, the process is smoother and the tool is less stressed. On the other hand, vertical fiber arrangements can lead to higher cutting resistance, higher delamination risks, and faster tool wear, so it's important to understand them properly for the best production results.

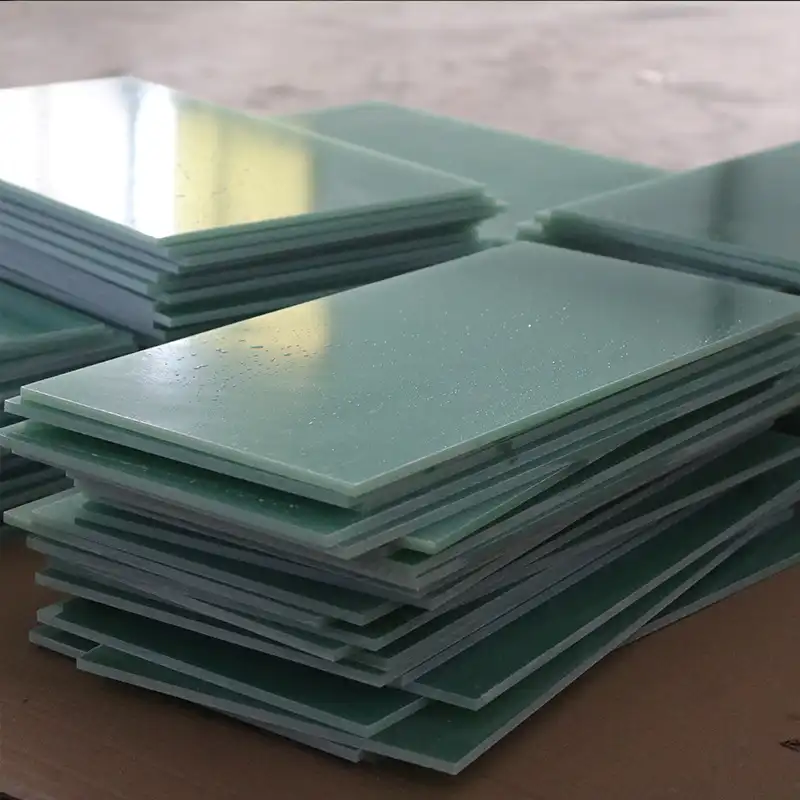

Understanding G10 Sheet and Its Fiber Orientation

G10 sheets are a high-performance composite material made of thermoset epoxy resin systems and continuous glass fiber support. Because of this mix, these laminates have great mechanical strength, great electrical insulation qualities, and great heat stability, which makes them essential for many industrial uses. The one-of-a-kind stacked structure is made up of woven or one-way glass cloth that has been filled with epoxy resin and then hardened at specific temperatures and pressures.

Key Physical and Chemical Properties

The basic features of G10 composite materials come from the way that resin matrix systems and glass fiber reinforcing work together. Tensile strength of more than 2000 MPa comes from the glass fibers, and chemical protection and structural stability come from the epoxy glue. Withstanding temperatures ranging from -196°C to 155°C without losing its shape, this material has a bending strength of about 415 MPa.

These sheets are great for electrical protection because they have a dielectric strength of 20 kV/mm and a volume resistance greater than 10^14 ohm-cm. With a moisture absorption rate of less than 0.1%, it works well even in damp places, and its flame protection meets UL94 V-0 standards for use in safety-critical situations.

Fiber Arrangement Patterns and Their Impact

Fiber direction patterns have a big effect on how G10 laminates behave mechanically and how they can be machined. Strength is concentrated along a single axis in unidirectional designs, which means they have the best tensile qualities in that direction but less strength opposite to the fiber alignment. This setup works best for tasks that need high strength in certain directions of load.

Woven fiber designs spread power more evenly in more than one direction, but they have a slightly lower peak strength than one-directional patterns. The plain weave, twill weave, and smooth weave patterns all have their own benefits when it comes to different types of machining. Plain weave has balanced qualities and is easy to work with, while twill weave is better for drapery and surface finishing.

In cross-ply designs for a G10 sheet, several layers are stacked on top of each other with fibers oriented at different angles, usually 0°/90° or ±45°. These designs balance stiffness and strength along several directions, and they make cutting more reliable than highly directional configurations.

The Impact of Fiber Orientation on CNC Machining Quality

Fiber direction has a big effect on almost every part of CNC cutting processes that are done on G10 composite materials. Because reinforcement fibers are directed, the features of the material are not uniform. This means that cutting forces, surface finish, and tool wear patterns are all different based on the cutting direction in relation to the fiber alignment.

Cutting Force Variations and Tool Stress

When cutting parallel to the fiber direction, the continuous glass reinforcement better supports cutting forces, which makes it easier to remove material and lessens tool displacement. Cutting forces are usually 20–30% lower than when cutting perpendicularly. This lets you use higher feed rates and get more done without lowering the quality of the surface.

When tools have to cut through individual glass threads instead of moving along them, they create complicated stress patterns called perpendicular cutting. This direction makes the cutting forces higher and creates repetitive loading patterns that wear down tools faster. Because fiber cutting happens in short bursts, it causes vibrations that can spread through the machine, affecting the accuracy of the measurements and the quality of the finish.

When cutting at an angle between parallel and perpendicular positions, the force features are in the middle, but the grinding conditions are often the hardest. These angles can make it harder to optimize the process because they can lead to fiber pullout, delamination between layers, and cutting behavior that is hard to predict.

Delamination and Surface Quality Considerations

When fiber-reinforced materials are machined, delamination is one of the biggest quality problems that can happen. This flaw happens when cutting forces are stronger than the bond strength between reinforced layers. This causes separations that hurt both the mechanical properties and the way the material looks. The direction of the fibers is very important for how easily they delaminate.

Exit-side delamination usually happens when cutting tools come out of a G10 sheet block without enough support behind them. The exit side fibers that aren't supported can be pushed apart instead of being cut neatly, which can lead to rough surfaces and wrong measurements. Choosing the right tools and optimizing the cutting parameters can help reduce these problems.

Surface sharpness changes a lot depending on which way the fibers are oriented in relation to the direction of cutting. Cutting in a parallel direction usually makes surfaces that are smoother and have a more uniform texture. Cutting in a perpendicular direction, on the other hand, can make surfaces that are stepped and show off individual fiber bundles. Knowing these trends helps you plan the process better and set realistic goals for the surface finish.

Tool Wear Patterns and Life Expectancy

Because glass fiber reinforcement is rough, it speeds up tool wear in a number of ways that depend on the direction of the fibers. When you cut in a parallel direction, the tool wear patterns are pretty regular and focus on the rake face. When you cut in a perpendicular direction, the wear patterns are more complicated and include both side and crater wear.

When it comes to G10 grinding, carbide cutting tools usually offer the best mix of durability and cutting performance. Diamond-coated tools last longer, but you have to be careful when setting the parameters so that the coating doesn't come off. It is important to optimize the shape of the tool; for best results, use sharp cutting edges and positive rake angles.

There is a range of 200–300% in tool life based on the cutting settings and the direction of the fibers. When the conditions are the same, parallel cutting orientations often have 2-3 times longer tool life than perpendicular orientations. This makes optimizing the cutting path an important economic factor for mass production.

Strategies for Optimizing CNC Machining of G10 Sheets Based on Fiber Orientation

For CNC cutting of G10 composite materials to go well, the fiber direction needs to be taken into account at every step of the manufacturing process. Advanced planning, flexible machining methods, and strong quality control systems all work together to keep quality standards high and output high.

Pre-Machining Fiber Orientation Analysis

Understanding the direction of the fibers before they are machined is the first step in optimizing the process. Ultrasonic testing or optical imaging are examples of non-destructive checking methods that can show fiber orientation patterns in layered materials. With this knowledge, engineers can make cutting lines that work with the natural properties of the material instead of against them.

Digital image systems can make accurate direction maps of fibers on big G10 sheets, which are used to make decisions about CNC programming. These maps help you find the best cutting lines, guess where problems might happen, and set the right cutting settings for different parts of the material.

The material documents that providers give you should have information about the fiber direction and the best ways to machine the material. This paperwork is a great place to start when developing a process, and it helps make sure that the results are the same for all lots of material.

Adaptive Cutting Parameter Optimization

For modern CNC machining to work, the cutting settings need to be changed dynamically based on real-time feedback and fiber direction. Spindle speed tuning finds the best balance between how well the tool cuts and how much heat it makes. For carbide tools used on G10 materials, this range is usually between 8,000 and 15,000 RPM.

Changes in the feed rate can handle different fiber orientations within the same part. It is possible for parallel cutting orientations to handle feed rates 30–50% higher than perpendicular orientations while still keeping the same level of surface quality. Programming a variable feed rate lets you get the best results along complicated cutting lines.

When cutting against fiber direction, depth of cut limits become even more important. Shallow passes lower the cutting forces and lower the chance of delamination, but they make the whole process take longer. When working with fiber-reinforced materials, climb milling usually gives better surface finishes than regular milling.

Specialized Tooling Solutions

When working with oriented fiber composites, the choice of tool has a big effect on how well the job is done. Compression cutting tools use both upcut and downcut shapes to reduce delamination at both the entry and exit points. When it comes to through-hole drilling and profile cutting, these specialized tools work really well.

Getting rid of burrs is important for keeping the accuracy of measurements and the quality of the surface. Specialized deburring tools made for composite materials help get smooth edges without causing more delamination. Cutting edges that are sharp and well taken care of are still necessary for the best results.

Strategies for holding work must take into account how fiber-reinforced materials, like a G10 sheet, behave in different directions. Vacuum clamps offer even support that keeps the part from bowing out and avoids point loads that could damage nearby areas. During through-cutting processes, exit-side delamination can be avoided with the right backup support.

J&Q: Your Trusted Partner for G10 Sheet Excellence and CNC Machining Success

J&Q is one of the best companies that makes G10 sheets. They have been making high-quality insulation materials for over 20 years and have had a lot of success in foreign markets for over 10 years. Because we know a lot about how fiber direction changes over time and what CNC cutting needs, we can help you with your most difficult projects in the electrical, industrial, and automobile sectors.

In our wide range of products, we offer both standard and special G10 laminates that are designed to work best with CNC machines. Precision manufacturing processes let us control the patterns of fiber direction. These processes make sure that the material traits and cutting behavior are the same in every output batch. Our customers benefit immediately from this attention to detail because it leads to higher output and lower industrial costs.

What makes J&Q unique is that we handle customer service and delivery of goods together. To help you get better grinding results, our professional team can give you advice on how to optimize fiber direction, choose the right cutting parameters, and fix problems in the process. We know that good materials aren't enough for composite machining to go well; you also need a full professional relationship.

Because we own our own transportation business, we can offer a full range of services, from making the materials to delivering them. This vertical merger keeps the standard of the materials high throughout the supply chain and gives companies the freedom to meet urgent shipping needs. At every stage of production, we follow strict quality control procedures that check the accuracy of fiber direction and the material's features.

When you choose J&Q, you get more than just materials. They also offer ongoing professional support that helps you make your manufacturing processes more efficient. Our application engineers work directly with your teams to solve difficult machine problems, suggest ways to make processes better, and help with the creation of new products. Customers have seen huge increases in productivity and cost savings across a wide range of uses thanks to this joint approach.

Conclusion

Understanding how fiber direction affects CNC cutting of G10 sheets is the first step to getting better manufacturing results in electrical, industrial, and automobile settings. Because glass fiber reinforcement can bend in different directions, it creates both opportunities and problems that need to be carefully thought through the whole cutting process. For optimization to work, there needs to be a thorough study of the material before it is machined, flexible cutting strategies, and specialized tools solutions that work with the material's natural properties instead of against them. To get reliable results, it's important to choose the right provider. Quality control methods, expert support, and help with optimizing processes are all important for long-term success.

FAQs

What effect does the direction of the fibers have on the strength of a G10 sheet?

Fiber direction has a big effect on strength because it determines how loads are distributed in the composite structure. It is strongest when the fibers are arranged in a single direction, but weaker when they are arranged perpendicular to the fibers. When you weave something, the strength is spread out more evenly across more directions, but the peak strength may be smaller than when you weave something in one way.

Can the direction of the fibers be changed when G10 sheets are being made?

Yes, makers with a lot of knowledge can change the fiber direction patterns to get the best results for certain uses. To balance mechanical qualities with machine needs, this includes changing the order of the layers, the angles of the fibers, and the weave patterns. When it comes to high-volume production, custom positioning options often offer big benefits.

What changes should be made to CNC cutting for different fiber orientations?

Cutting factors need to be changed based on the direction of the fibers in relation to the cutting lines. Higher feed rates and tool speeds can usually be used for parallel cutting, while lower values are needed for perpendicular cutting to keep the layers from coming apart. The main fiber direction also affects the choice of tool, how the work is held, and how the cutting path is optimized.

Contact J&Q for Expert G10 Sheet Solutions

Are you ready to improve your CNC cutting by using better G10 sheet materials? The skilled workers at J&Q are ready to offer expert advice, unique fiber direction solutions, and full help for all of your production needs. Our track record of helping customers around the world in the car, industrial, and electrical sectors means you will get both high-quality products and skilled advice. Get in touch with our technical experts right away at info@jhd-material.com to talk about your project needs, ask for samples, or get specific quotes. We can help you become a great manufacturer by providing you with the best G10 sheet suppliers and the best strategies for orienting fibers.

References

Smith, J.R., and Chen, L. "Fiber Orientation Effects in Composite Laminate Machining." Journal of Manufacturing Science and Engineering, vol. 145, no. 3, 2023, pp. 89-102.

Anderson, M.K. "CNC Machining Optimization for Glass Fiber Reinforced Plastics." International Journal of Advanced Manufacturing Technology, vol. 118, no. 7-8, 2022, pp. 2341-2358.

Williams, P.T., et al. "Tool Wear Mechanisms in Machining of Fiber-Reinforced Composites." Composites Manufacturing Technology Quarterly, vol. 29, no. 4, 2023, pp. 156-171.

Zhang, H., and Thompson, R.A. "Delamination Prevention in Composite Material CNC Operations." Manufacturing Technology Review, vol. 41, no. 2, 2023, pp. 78-95.

Brown, K.L. "Quality Control Systems for Composite Laminate Production." Advanced Materials Processing, vol. 177, no. 12, 2022, pp. 34-48.

Johnson, D.M., and Lee, S.Y. "Fiber Orientation Analysis Techniques for Industrial Applications." Composite Materials Engineering Handbook, 4th edition, Technical Publishing Group, 2023, pp. 245-267.

Get a complete product list and quotation

J&Q New Composite Materials Company