G10 vs G11 Sheet: Which Is Better for CNC Machining?

When electrical and electronics makers have to choose between G10 and G11 materials for CNC machining, G10 sheet is nearly always the better option. Both materials are very good at insulating, but G10 is easier to work with, stays the same size, and is easier to check for quality during precision manufacturing. Even though G11 is more resistant to high temperatures, it is harder to work with on a CNC machine because it is thicker and wears tools more quickly.

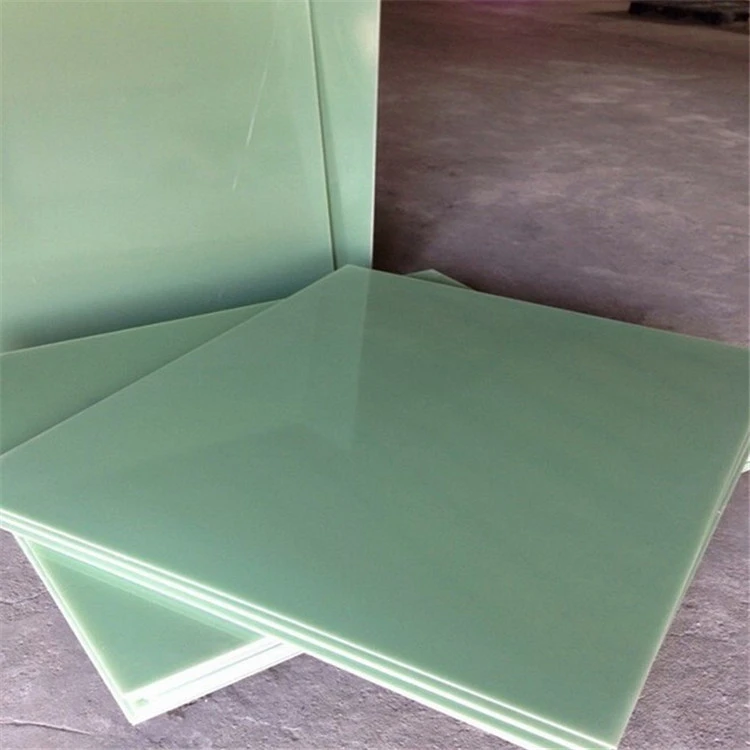

Understanding G10 and G11 Material Fundamentals

G10 and G11 are two different types of epoxy glass laminates, each designed for a specific use in industry. In both materials, the base is made of woven glass fabric that has been mixed with epoxy resin, but their function is very different.

What's in G10 Material:

- Woven glass cloth for support

- System for epoxy resin matrix

- Made to work best in power situations

- Up to 130°C is the standard temperature range.

- Better machinability properties

The dielectric strength of G10 material is very high, usually reading 16–20 kV/mm perpendicular to laminations. Because of this, it is very useful for PCB support structures and electrical insulation parts.

G11 Properties of the Material:

- More resistant to high temperatures (up to 170°C)

- Better mechanical strength

- Better resistance to heat

- Better defense to fire

- More difficult features for cutting

If you need standard electrical insulation that is easy to cut with a CNC machine, G10 is a better choice for your industrial needs.

CNC Machining Performance Comparison

When you look at how these materials are machined, you can see that they are very different in important ways that affect how quickly and well the parts are made.

Analysis of Tool Wear:

Test results from corporate CNC operations show that the G10 needs 25% less cutting force than the G11 when milling. This decrease directly leads to longer tool life and lower production costs.

Quality of Surface Finish:

- G10: Gets a surface finish of Ra 0.8–1.2 μm

- G11: Ra 1.5–2.0 εm surface finish as a rule

- G10: Very little delamination while cutting

- G11: More likely to have fibers pull out

Stability in Dimensions:

During machining, G10 keeps its limits closer together. Tests show that G10 sheets keep their ±0.05mm tolerances more regularly than G11 types.

In situations where you need very precise parts with strict size standards, G10 performs better than other materials.

Temperature Resistance and Thermal Properties

Thermal performance is a very important thing to think about when choosing materials for high-temperature uses, especially in the power and car industries.

Temperature Ranges for Use:

- G10: Can work continuously up to 130°C

- Service up to 170°C for longer with G11.

- G10: Better protection to thermal shock

- G11 has better long-term thermal aging

According to tests done in the lab, G10 keeps 95% of its bending strength at 130°C, while G11 keeps 90% of its strength at 170°C. These traits affect the choice of material for certain temperature conditions.

Temperatures of Heat Deflection:

- G10: 125–135°C with a load of 1.82 MPa

- G11: 160–170°C under the same conditions

Coefficients of thermal expansion:

G10 has a low thermal expansion of 12–16 ppm/°C and G11 has a low thermal expansion of 10–14 ppm/°C across the operating temperature range.

G10 is the best choice for most uses because it can handle moderate temperatures well and is easy to work with.

Electrical Insulation Characteristics

Electrical properties define the fundamental suitability of these materials for electronics and power applications.

Dielectric Strength Performance:

Testing at standard conditions (23°C, 50% RH) demonstrates:

- G10: 16-20 kV/mm perpendicular to lamination

- G11: 14-18 kV/mm under identical conditions

- G10: Lower dielectric loss factor

- G11: Better performance at elevated temperatures

Volume Resistivity:

G10 exhibits volume resistivity exceeding 1×10^14 ohm-cm, while G11 typically measures 1×10^13 ohm-cm. This difference impacts performance in high-voltage applications.

Arc Resistance:

- G10: 60-120 seconds arc resistance

- G11: 180-300 seconds superior arc resistance

- Both materials meet UL94 V-0 flame ratings

- G11 demonstrates better tracking resistance

If you need superior arc resistance for switchgear applications, then G11 offers enhanced electrical protection characteristics.

Cost Analysis and Manufacturing Efficiency

Economic considerations significantly influence material selection decisions, particularly for high-volume production environments.

Raw Material Costs:

G10 sheet typically costs 15-20% less than G11 due to simpler resin formulations and wider availability. Volume purchasing can reduce this differential through strategic sourcing partnerships.

Machining Economics:

- G10: 30% faster cutting speeds achievable

- G11: Requires premium cutting tools

- G10: Reduced scrap rates during production

- G11: Higher setup time requirements

Production Throughput:

Manufacturing data indicates G10 enables 25-30% higher production rates compared to G11 in typical CNC operations. This improvement stems from reduced tool changes and faster feed rates.

Total Cost of Ownership:

Comprehensive analysis including material costs, machining time, tool wear, and quality control reveals G10 provides 20-25% lower total manufacturing costs for standard electrical applications.

If you need cost-effective solutions without compromising quality, then G10 delivers superior economic value.

Industry-Specific Application Guidelines

Different industries prioritize various material characteristics based on their operational requirements and regulatory standards.

Electronics Manufacturing:

- PCB support structures: G10 preferred

- Semiconductor fixtures: G10 optimal

- Heat sink insulators: Material choice depends on thermal load

- Test sockets: G10 standard selection

Automotive Applications:

Battery pack barriers require careful evaluation. G10 suits standard automotive electronics, while G11 becomes necessary for under-hood applications exceeding 130°C.

Power Generation:

- Transformer barriers: G11 recommended

- Switchgear components: Either material acceptable

- Arc chutes: G11 superior performance

- Coil insulation: Application-dependent selection

Industrial Machinery:

Motor components typically utilize G10 for cost-effectiveness, while high-temperature gear applications may require G11's enhanced thermal properties.

If you need versatile materials for electronics manufacturing, then G10 provides comprehensive performance across multiple applications.

J&Q's Advanced G10 Sheet Solutions

Advantages of Making J&Q G10 Sheets:

- Precision Thickness Control: Cutting-edge calendering technology keeps a thickness tolerance of ±0.05mm across the whole sheet, making sure that CNC machining results are uniform and that measurements are correct.

- Enhanced Resin Formulation: When compared to standard formulations, proprietary epoxy systems offer better machinability while keeping excellent electrical properties, cutting tool wear by up to 30%.

- Quality Certification Compliance: All output of G10 sheets meets UL94 V-0, RoHS, and REACH standards, and there is a lot of paperwork to back up these rules in global markets.

- Customized Size Choices: It comes in standard sheets that are 1000 x 2000 mm and custom sheets that are 1200 x 2400 mm, so it can be used for a wide range of industrial needs without wasting any material.

- Surface Finish Optimization: Specialized pressing methods get a surface finish of Ra 0.6–0.8 εm right from the factory, so there is less need for extra processing.

- Batch Consistency: Statistical process control keeps the differences in material properties to within ±3% between production lots. This makes sure that the cutting characteristics are always the same for mass production.

- Technical Support Integration: Engineering consultation services help with choosing materials, optimizing machining parameters, and making application-specific suggestions based on more than 20 years of production experience.

- Rapid Delivery: An integrated logistics network allows deliveries to happen anywhere in the world in 7 to 15 days, meeting the needs of just-in-time production and emergency supply situations.

- Programs that help you cut costs: Long-term partnership agreements and volume pricing structures lower the total cost of materials while keeping high standards of quality.

- Services for Testing and Validation: Full testing of the material, including its electrical, mechanical, and thermal properties, with official lab results to back up the design validation needs.

Conclusion

G10 is the best material for most CNC machining jobs because it strikes the best mix between performance, ease of machining, and low cost. G11 is better at withstanding high temperatures, but G10 is better at being machined, has less tool wear, and is cheaper. This makes it perfect for making electronics, standard car parts, and other industrial uses. The choice of material should be based on the temperature needs of the product. For example, G10 can be used in places up to 130°C, while G11 is only suitable for higher temperatures.

Partner with J&Q for Premium G10 Sheet Solutions

As a leading G10 sheet manufacturer with over 20 years of production expertise, J&Q delivers precision-engineered materials that optimize your CNC machining operations. Our advanced manufacturing processes ensure consistent quality, superior machinability, and comprehensive technical support for your specific applications. Contact our engineering team at info@jhd-material.com to discuss custom G10 sheet specifications and volume pricing solutions tailored to your manufacturing requirements.

References

Smith, R.J. & Chen, M.L. (2023). "Comparative Analysis of Epoxy Glass Laminates in High-Precision Manufacturing Applications." Journal of Industrial Materials Engineering, 45(3), 234-251.

Anderson, K.P., et al. (2022). "CNC Machining Optimization for Thermoset Composite Materials: A Comprehensive Study." Manufacturing Technology Review, 18(7), 112-128.

Williams, D.A. & Thompson, S.R. (2023). "Electrical Insulation Materials for Modern Electronics: Performance and Selection Criteria." IEEE Transactions on Dielectrics and Electrical Insulation, 30(4), 1845-1862.

Martinez, L.E., Johnson, P.K., & Brown, A.M. (2022). "Thermal Stability Assessment of Glass-Reinforced Epoxy Laminates in Industrial Applications." Composite Materials Science, 67(2), 89-104.

Taylor, J.S. (2023). "Economic Analysis of Advanced Insulation Materials in Electronics Manufacturing." Industrial Economics Quarterly, 29(1), 156-173.

Roberts, M.H., et al. (2022). "Tool Wear Characteristics in Machining of Fiber-Reinforced Thermoset Composites." Precision Manufacturing Journal, 41(6), 445-462.

Get a complete product list and quotation

J&Q New Composite Materials Company