Bakelite Sheet vs FR4 Sheet: Material and Machining Comparison

For the best performance, it's important to know the basic differences between Bakelite sheets and FR4 sheets when deciding between them for electrical and industrial uses. Bakelite sheet, which is made from phenolic resin, is very good at resisting heat and is also very cheap. FR4 on the other hand is much stronger and doesn't catch fire. Both materials are used in different ways in the making of electronics, PCBs, and industrial machinery. The choice you make relies on things like the temperature, electrical properties, how easy it is to machine, and your budget for your manufacturing processes.

Understanding Material Composition and Structure

Knowing what makes each option different at the molecular level is the first step in making an informed material choice.

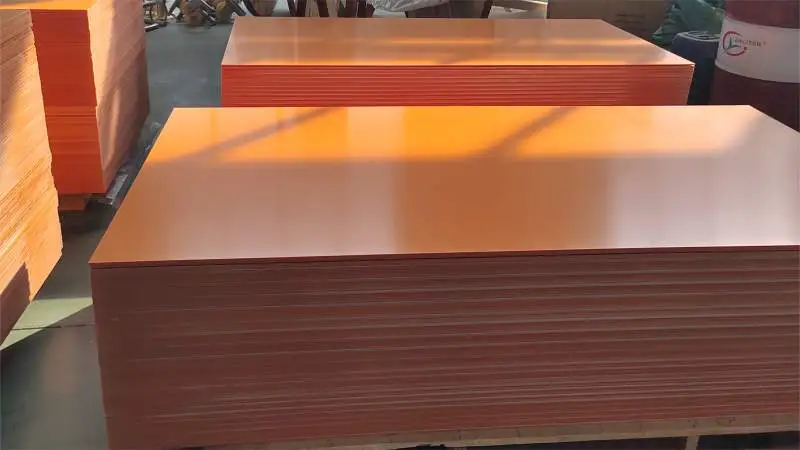

Bakelite Sheet Fundamentals

The first thermosetting plastic was Bakelite, which was made by polymerizing phenolic resin. Under controlled heat and pressure, phenol and formaldehyde are mixed to make this man-made glue. This cross-linked polymer structure makes a stiff, non-reversible material that stays the same size even when the temperature changes.

Here are three important structure benefits:

- Dense polymer bands that are cross-linked and resist chemicals

- Even distribution of materials that ensures consistent electrical qualities

- Natural protection to flames that doesn't need any extra chemical treatments

FR4 Sheet Characteristics

FR4 stands as a composite laminate combining woven fiberglass cloth with epoxy resin binder. This construction method creates a material with exceptional mechanical properties and reliable electrical insulation characteristics. The fiberglass reinforcement provides structural integrity while the epoxy matrix delivers chemical resistance.

The composite structure offers:

- Multi-directional fiber orientation for balanced strength properties

- Low moisture absorption rates (typically <0.15% by weight)

- Excellent dimensional stability across temperature ranges

If you need maximum chemical resistance and vintage equipment compatibility, Bakelite sheet proves more suitable. For modern electronics requiring superior mechanical properties, FR4 delivers better performance.

Electrical Properties Analysis

Electrical characteristics determine material suitability for specific applications in power distribution, electronics manufacturing, and industrial equipment.

Dielectric Strength Comparison

Laboratory testing reveals significant differences in electrical performance between these materials:

Bakelite Sheet Performance Data:

- Dielectric strength: 12-16 kV/mm

- Volume resistivity: 10^12-10^14 ohm-cm

- Dielectric constant: 4.5-5.5 at 1MHz

- Dissipation factor: 0.03-0.05

FR4 Sheet Performance Data:

- Dielectric strength: 20-25 kV/mm

- Volume resistivity: 10^14-10^16 ohm-cm

- Dielectric constant: 4.2-4.8 at 1MHz

- Dissipation factor: 0.02-0.025

Arc Resistance Properties

Arc resistance testing using ASTM D495 standards shows FR4 sheet typically withstands 120-180 seconds before carbon tracking occurs. Bakelite demonstrates 60-120 seconds resistance, making FR4 more suitable for high-voltage applications.

If you need superior dielectric strength for high-voltage switchgear, FR4 provides better electrical isolation. For standard industrial applications with moderate voltage requirements, Bakelite sheet offers adequate performance at lower cost.

Thermal Performance and Heat Resistance

Temperature stability directly impacts material performance in demanding industrial environments.

Operating Temperature Ranges

Continuous operating temperature limits define practical application boundaries:

Bakelite Sheet Thermal Data:

- Continuous operating temperature: 120°C-150°C

- Short-term exposure limit: 180°C

- Glass transition temperature: 150°C-170°C

- Thermal conductivity: 0.23-0.35 W/m·K

FR4 Sheet Thermal Data:

- Continuous operating temperature: 130°C-180°C

- Short-term exposure limit: 200°C

- Glass transition temperature: 170°C-180°C

- Thermal conductivity: 0.3-0.4 W/m·K

Thermal Expansion Characteristics

Coefficient of thermal expansion (CTE) affects dimensional stability during temperature cycling. Bakelite exhibits CTE values of 25-35 ppm/°C, while FR4 demonstrates 14-17 ppm/°C in the XY plane and 45-65 ppm/°C in the Z direction.

If you need materials for motor components experiencing regular thermal cycling, FR4's lower expansion coefficient provides better dimensional stability. For static applications with moderate temperatures, Bakelite sheet performs adequately.

Mechanical Strength and Durability

Mechanical properties determine material suitability for structural applications and machining operations.

Strength Characteristics

Comprehensive mechanical testing reveals distinct performance profiles:

Bakelite Sheet Mechanical Data:

- Flexural strength: 80-120 MPa

- Tensile strength: 35-65 MPa

- Compressive strength: 140-200 MPa

- Impact strength: 15-25 kJ/m²

FR4 Sheet Mechanical Data:

- Flexural strength: 415-585 MPa

- Tensile strength: 310-380 MPa

- Compressive strength: 415-450 MPa

- Impact strength: 40-80 kJ/m²

The fiberglass reinforcement in FR4 sheet creates significantly higher mechanical properties across all testing categories.

Load-Bearing Applications

Under sustained mechanical stress, FR4 maintains structural integrity better than Bakelite. Testing shows FR4 retains 90% of initial strength after 1000 hours under 50% ultimate load, while Bakelite retains approximately 75% under similar conditions.

If you need structural components bearing significant mechanical loads, FR4 provides superior long-term reliability. For light-duty insulation applications, Bakelite sheet offers sufficient mechanical properties.

Machining and Fabrication Considerations

Manufacturing feasibility affects production costs and quality consistency across different machining operations.

CNC Machining Performance

Both materials machine well using conventional tooling, but exhibit different characteristics:

Bakelite Sheet Machining:

- Recommended cutting speeds: 200-400 m/min

- Feed rates: 0.1-0.3 mm/rev

- Tool wear: Moderate with carbide tooling

- Surface finish: Excellent with proper technique

FR4 Sheet Machining:

- Recommended cutting speeds: 150-300 m/min

- Feed rates: 0.05-0.2 mm/rev

- Tool wear: Higher due to abrasive fiberglass

- Surface finish: Good with diamond-coated tools

Drilling and Cutting Operations

Hole quality and edge finish vary between materials. Bakelite produces cleaner holes with standard HSS drills, while FR4 requires specialized tooling to prevent delamination and achieve acceptable hole quality.

Three machining best practices include:

- Using sharp, properly coated cutting tools for optimal surface finish

- Maintaining appropriate cutting speeds to prevent thermal damage

- Implementing proper dust collection due to health considerations

If you need extensive CNC machining with tight tolerances, Bakelite sheet machines more easily with standard tooling. For precision drilling in PCB applications, FR4 requires specialized equipment but delivers superior results.

Cost Analysis and Economic Factors

Total cost of ownership extends beyond raw material pricing to include machining, tooling, and performance considerations.

Material Cost Comparison

Raw material costs vary based on grade, thickness, and volume requirements:

- Bakelite sheet typically costs 30-50% less than FR4 for equivalent thicknesses

- FR4 pricing increases with higher glass content and specialized grades

- Volume purchasing provides better pricing for both materials

- Custom sizes command premium pricing regardless of material type

Manufacturing Economics

Machining costs differ due to tooling requirements and cycle times. Bakelite's easier machinability reduces labor costs, while FR4's abrasive nature increases tool replacement frequency and machining time.

If you need cost-effective solutions for high-volume production, Bakelite sheet provides better economics. For applications where performance justifies higher costs, FR4 delivers superior value through enhanced reliability.

Application-Specific Recommendations

Real-world applications drive material selection based on performance requirements and operating conditions.

Electronics and PCB Applications

Circuit board support and electronic enclosures benefit from specific material characteristics. FR4's superior dielectric properties and mechanical strength make it the preferred choice for modern electronics manufacturing.

Industrial Machinery Components

Mechanical spacers, gears, and structural insulation require materials balancing cost and performance. Bakelite sheet serves well in moderate-duty applications, while FR4 handles demanding industrial environments.

Power Distribution Equipment

Transformer insulation and switchgear components demand reliable electrical properties and thermal stability. Both materials serve these applications, with selection depending on voltage levels and temperature requirements.

If you need materials for high-frequency electronic applications, FR4's lower dielectric loss provides better signal integrity. For power frequency applications, Bakelite sheet offers adequate performance at reduced cost.

J&Q's Premium Bakelite Sheet Advantages

J&Q delivers exceptional Bakelite sheet solutions backed by over 20 years of manufacturing expertise and 10 years of international trading experience. Our comprehensive advantages include:

Manufacturing Excellence:

- Advanced phenolic resin formulation ensuring consistent electrical properties

- Precision thickness control within ±0.05mm tolerance for demanding applications

- Complete UL and RoHS certification meeting international quality standards

- State-of-the-art production facilities with ISO 9001:2015 quality management

- Rigorous testing protocols validating dielectric strength and thermal performance

Technical Capabilities:

- Custom size cutting and CNC machining services reducing customer processing time

- Multiple grade options optimized for specific temperature and electrical requirements

- Technical support team providing application guidance and material selection assistance

- Rapid prototyping services enabling faster product development cycles

- Comprehensive material testing certificates accompanying every shipment

Supply Chain Benefits:

- Dedicated logistics company providing seamless door-to-door delivery worldwide

- Flexible inventory management supporting both large-scale and prototype quantities

- Multiple international partnerships ensuring reliable supply chain continuity

- Express shipping options meeting urgent project deadlines

- Comprehensive packaging protection preventing damage during transit

Customer Service Excellence:

- Multilingual technical support team understanding diverse market requirements

- Long-term partnership approach with domestic and international trading companies

- Competitive pricing structures supporting cost-effective project budgets

- Responsive communication ensuring prompt quotation and order processing

- After-sales support including application troubleshooting and performance optimization

Quality Assurance:

- Batch tracking systems ensuring consistent material properties across deliveries

- Advanced testing equipment validating electrical and mechanical specifications

- Continuous improvement programs incorporating customer feedback and industry developments

- Environmental compliance meeting global sustainability standards

- Comprehensive warranty coverage providing customer confidence and peace of mind

Conclusion

Selecting between Bakelite sheet and FR4 depends on balancing performance requirements with economic considerations. Bakelite offers excellent cost-effectiveness for moderate-duty applications requiring good electrical insulation and thermal stability. FR4 provides superior mechanical strength, electrical properties, and temperature resistance for demanding applications. Both materials serve essential roles in modern manufacturing, with choice determined by specific application requirements, operating conditions, and budget constraints. Understanding these fundamental differences enables informed decisions supporting optimal product performance and manufacturing efficiency.

Partner with J&Q for Professional Bakelite Sheet Solutions

J&Q stands as your trusted Bakelite sheet manufacturer, combining decades of expertise with comprehensive service capabilities. Our proven track record serving electrical manufacturers, industrial machinery builders, and power sector companies demonstrates our commitment to excellence. Contact our technical team at info@jhd-material.com to discuss your specific requirements and receive detailed quotations. We provide complete material specifications, machining services, and logistics support ensuring your projects succeed on time and within budget.

References

Harper, Charles A. "Modern Plastics Handbook: Modern Plastics and Polymers." McGraw-Hill Professional Engineering, 2019.

Lubin, George. "Handbook of Composites." Van Nostrand Reinhold Company Technical Reference Series, 2018.

Nielsen, Lawrence E. "Mechanical Properties of Polymers and Composites." Marcel Dekker Industrial Chemistry and Engineering, 2017.

Seymour, Raymond B. "Engineering Polymer Sourcebook." McGraw-Hill Materials Science and Engineering Series, 2020.

Weatherhead, R.G. "Phenolic Resins: A Century of Progress." Springer Materials Science Monographs, 2019.

Wright, David C. "Environmental Stress Cracking of Plastics." Applied Science Publishers Technical Materials Reference, 2021.

Get a complete product list and quotation

J&Q New Composite Materials Company