When it comes to epoxy laminates, choosing between CNC routing and cutting has a big effect on the quality of the making, the cost, and the wait time. Both routing and milling are great ways to work with composite insulation materials, but routing is faster and cheaper, while milling is better for precise work and smooth surfaces in industrial settings that need a lot of power.

Understanding Epoxy Laminates in Manufacturing

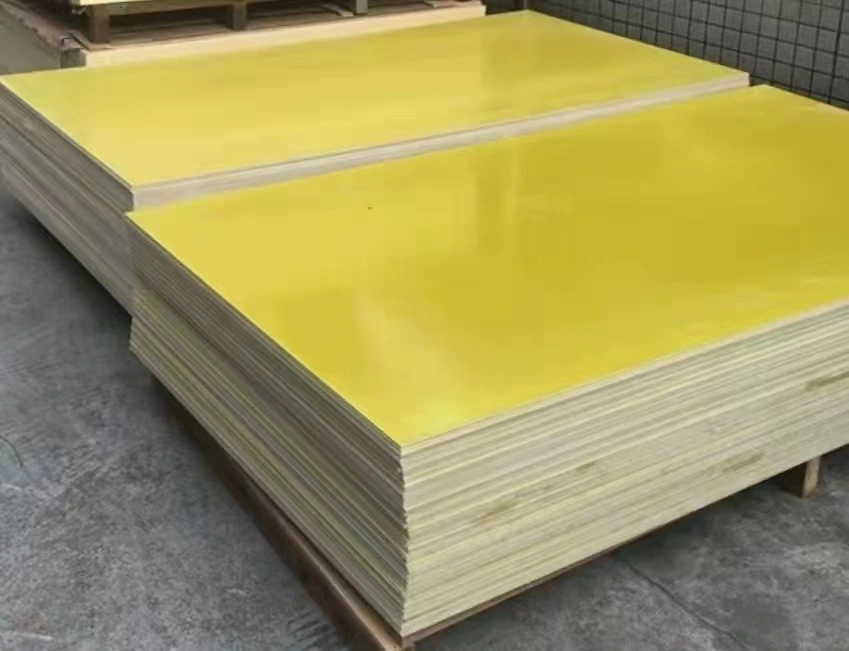

Epoxy laminates are an important part of modern industry, especially in electronics and other fields where efficiency and dependability are very important. By combining glass fiber or cotton cloth support with epoxy resin systems, these composite materials make materials that are very good at insulating electricity and being very strong.

A lot of different businesses use these materials because they have a special mix of qualities that make them necessary in many fields. These materials regularly work better than standard ones in harsh settings with temperature changes, chemical exposure, and mechanical stress. They are used in everything from printed circuit board surfaces to high-voltage insulation barriers.

What Are Epoxy Laminates and Their Core Properties?

Composite shielding materials based on epoxy glue science can be used in a huge range of industrial settings. The basic structure is made up of strengthening fibers that have been soaked in thermosetting epoxy resin. When the resin hardens, it creates a material that is strong, stable in shape, and has great insulating qualities.

Some important performance features are a dielectric strength of more than 20 kV/mm, a working temperature range of up to 180°C, and a compression strength of up to 400 MPa. These materials keep their features over a wide range of temperatures. They also don't absorb water or chemicals or change size, which can happen with other insulation materials.

The glass transition temperature of good epoxy systems makes sure that they work reliably in places like power distribution equipment, under-hood uses in cars, and industrial gear where temperatures change often. Because these materials are stable at high temperatures and are easy to machine, they are the best choices for making accurate parts that need to be within very tight tolerances.

Why Machining Matters: Challenges with Epoxy Laminates?

Unlike metals or thermoplastics, epoxy laminates are hard to work with in ways that are unique to them. When hard glass fibers are mixed with a brittle plastic matrix, it makes it difficult to machine. The choice of tool, the cutting settings, and the workholding tactics become very important.

When cutting, the main thing to worry about is delamination, which happens when cutting forces split the fiber-resin contact or cause inter-laminar fails. When you cut something, the heat from the blade can soften the plastic in some places. This can result in rough surfaces and wrong measurements that make the part less useful in electrical uses.

CNC Routing for Epoxy Laminates: Process and Advantages

CNC routing technology has changed the way composite insulation materials are processed by giving makers a quick and easy way to make exact cuts and complicated forms. For this type of machining, high-speed machines with cutting tools made just for fiber-reinforced composite materials are used.

The routing process is great for tasks that need to quickly remove material while still leaving a good surface finish. This makes it especially useful for making prototypes and medium-sized production runs. These days' CNC cutters have very powerful control systems that let them keep the same cutting settings even when the materials in composite laminates change.

What is CNC Routing and How Does It Work on Epoxy Laminates?

A vertical spindle moves the cutting tool along pre-programmed routes while the item stays still on the machine table. This is how CNC routing works. Spindle speeds are usually between 15,000 and 30,000 RPM. These are the right speeds to cut glass threads smoothly without building up too much heat.

Diamond-coated carbide tools work best for routing because they last longer and keep their sharp cutting edges, which are necessary for clean fiber cutting. The high-speed, low-force cutting action reduces the risk of delamination while allowing work on small details that would not be possible with traditional methods of grinding.

Benefits of CNC Routing for Epoxy Laminates

The main benefit of route technology for epoxy laminates is that it speeds up production; cycle times are often 50–70% shorter than those of similar milling processes. Routing is great for making large holes, complicated perimeters, and detailed interior features that are needed in electrical insulation components because it can remove a lot of material quickly.

When it comes to cost, routing is often the best option, especially when the surface finish needs to be able to handle the slightly rough finish that comes with routed surfaces. Compared to milling blades, the cost of tools stays low, and the cost of buying a machine is usually cheaper than for precision milling centers.

Limitations and Considerations of CNC Routing

Surface finish quality is the main problem with routing methods; surfaces that have been routed have more roughness than surfaces that have been cut. This trait could be a problem in situations where smooth surfaces are needed for electrical reasons or for looks.

Routing uses are also limited by the width of the material; materials less than 10 mm thick work best. When compared to milling methods made for heavy-duty cutting, thinner parts may have higher delamination risks and less accurate measurements.

CNC Milling for Epoxy Laminates: Process and Advantages

For composite insulation materials, CNC milling technology offers the highest level of accuracy and surface quality. It uses rigid, multi-axis machines made for difficult cutting tasks. This method is necessary when the specs for a part call for very accurate measurements and smooth surfaces.

When milling, lower machine speeds and controlled feed rates are used to keep heat production low and cutting tool contact high. This cautious method works really well in thick parts and complicated shapes where route problems become clear.

Overview of CNC Milling and Its Application to Epoxy Laminates

End mills and other specialized composite cutting tools are used in milling epoxy laminates. Spindle speeds are between 8,000 and 18,000 RPM, which is much slower than in routing. When positive rake angle shapes are paired with slower cutting speeds, they make a controlled cutting action that reduces fiber pullout and resin chipping.

It is very important for machines to be stiff when milling. Good machining centers have the structural support needed to keep tight tolerances during long cutting processes. Workholding systems must properly spread clamping forces to keep the part from warping and provide enough support for cutting forces.

Advantages of CNC Milling for Epoxy Laminates

The best thing about milling technology is its surface finish quality. When processes are properly adjusted, surfaces are made that are as smooth as glass and can be used in the toughest situations. Dimensional accuracy is better than route performance, and in production settings, errors of less than ±0.05mm are possible.

With its thick section capability, milling can work with materials up to 50 mm thick and still keep the accuracy and quality of the surface. With multi-axis milling centers, you can make complex three-dimensional shapes, which gives you design options that you couldn't get with routing technology.

Common Challenges in Milling Epoxy Laminates

The roughness of the glass fiber infill makes tool wear go up a lot during cutting processes. To get a good tool life, carbide tools might need diamond finishes or PCD cutting edges. This makes the cost of each part of the manufacturing higher compared to turning processes.

When compared to routing, cycle times are much longer because complex parts need more than one action and tool changes. The ability to be precise comes at the cost of lower productivity, which makes it hard to make the business case for simple shapes or high-volume uses.

CNC Routing vs Milling: Comparative Analysis for Epoxy Laminates

Knowing how routing and milling work differently helps buying teams make smart choices that match the need for quality with the facts of cost. Each method has its own benefits that depend on the application and the amount of work that needs to be done.

During the decision process, many things need to be carefully thought through, such as the shape of the part, the tolerances that need to be met, the surface finish standards, and the production volume. These things, along with cost factors, help figure out the best way to machine something for a certain job.

Performance Parameters Compared

When it comes to dimensional accuracy for epoxy laminates, the two methods are very different. Milling can achieve limits of ±0.05mm, while turning can usually achieve ±0.1mm accuracy. Measurements of surface roughness show similar differences, with cut surfaces having Ra values below 1 micron and routed surfaces having Ra values around 3.2 microns.

Processing speeds are better for winding processes because they remove more material than milling by two to three times. However, milling makes up for it by being more consistent and producing fewer scraps, especially when working with difficult materials or complicated shapes that routing might have trouble with.

Cost Considerations and ROI for B2B Clients

The economic study needs to look at both the direct costs of cutting and the costs of other processes that need to be done to meet the end requirements. Routing processes usually cost 30 to 50 percent less per part, but they might need extra steps to finish to meet quality standards for the surface.

Operating costs are greatly affected by changes in tool life. Routing tools last two to three times longer than milling cuts because they produce less heat and cutting force. Routing is better for simple shapes because it uses machines more efficiently, but milling is better for parts that need to be set up more than once.

Application-Based Recommendations

When surface roughness doesn't affect electrical performance, routing's speed benefits are useful for electrical insulation uses. PCB cutting and cutout processes are great examples of route tasks where speed and cost are more important than surface finish.

For precise mechanical parts that need tight specs and smooth surfaces, grinding is worth the extra cost because it makes assembly easier and improves performance. Milling is often the best way to meet electrical clearance standards for power delivery parts and high-voltage insulators.

How to Choose the Right Machining Process for Your Epoxy Laminates – A Procurement Perspective?

To choose the right cutting process, you need to carefully look at the technical needs, the cost, and the supplier's skills. Teams in charge of buying things have to weigh a lot of different factors and make sure that the processes they choose are in line with their long-term output and quality goals.

The framework for making the choice should take into account both current and future needs, taking into account how production numbers, design complexity, and quality standards may change over time. This forward-looking method keeps process changes from being too expensive and makes sure that industrial solutions can be expanded.

Defining Decision Criteria for B2B Buyers

The choice of method for epoxy laminates is based on technical requirements, such as the thickness of the material, the limits for size and finish, and the technical requirements for the surface finish. Projections of production volumes affect the choice of tools and tactics for improving the process.

Quality system standards, such as the need for tracking, paperwork, and licensing, may prefer providers with more advanced skills, even if the raw materials cost more. Delivery times and limited capacity are often the deciding factors in which provider to choose.

Matching Production Needs with Machining Solutions

Routing's freedom and ability to be set up quickly are usually preferred in low-volume, high-mix output situations. Milling may be worth the higher setup costs for high-volume jobs with uniform shapes because it improves the quality of each part and cuts down on extra processes.

Routing's quick turn-around times make it better for prototyping and development, while milling's better repeatability and physical control make it better for production parts that need to be consistent over time.

Trends and Innovations Influencing Epoxy Laminates Machining

Newer technologies for tools keep making turning and milling work better. For example, diamond-coated tools last longer while still being sharp on the cutting edge. Adaptive machine controls change settings automatically based on the cutting conditions at the time of the cut. This improves surface quality and cuts down on cycle times.

Because hybrid machining machines can do both turning and milling, they give you the freedom to use the best process for each part. These systems make it possible to make complicated parts that need both quick removal of material and precise finishing processes at a low cost.

Partner with J&Q for Premium Epoxy Laminate Solutions

J&Q is a reliable seller of epoxy laminates because they have been making things for over 20 years and have been dealing internationally for ten years. Because we know a lot about what CNC machines need, we can offer materials that are especially designed to work best for both turning and cutting.

Our wide range of products includes both standard and custom-made composite materials that are made to meet a wide range of performance and industry standards. In addition to our materials, we offer services that add value, such as expert advice, the ability to make things to order, and fast international shipping through our own transportation business.

Quality control is still very important to us. We strictly follow international standards and use sustainable sourcing methods to keep clients trusting us throughout the whole process of buying and making things. Our dedication to quality makes sure that every package meets the requirements and helps your industrial business succeed.

Conclusion

When it comes to epoxy laminates, the choice between CNC turning and cutting comes down to matching performance needs with cost considerations. For tasks that can handle slightly rough surfaces, routing is the fastest and most cost-effective option. On the other hand, milling provides the best accuracy and surface quality for tough tasks. When buying teams understand these trade-offs, they can make the best decisions about how to machine parts so that they meet standards and prices stay low. The important thing is to make sure that the process's abilities match the needs of the application, taking into account both short-term wants and long-term output goals.

FAQs

Can thick epoxy laminate sheets be routed well with a CNC?

The best materials for CNC cutting are those that are less than 10 mm thick. Even though bigger pieces can be routed, milling usually works better for materials over 15 mm thick because it's easier to control the cutting force and there are fewer chances of delamination.

What factors have the biggest impact on the quality of the surface finish in composite machining?

The main things that affect surface finish are how sharp the tool is, how fast it cuts, and how fast it feeds. Diamond-coated tools, optimal spindle speeds, and good chip removal reduce fiber loss and resin chipping, which hurt the quality of the surface.

How can I tell which is better for my output needs: routing or milling?

Check the tolerances, surface finish, material thickness, and output quantities that are needed. Routing is best for jobs that need to be done quickly and cheaply and have tolerances of more than ±0.1mm. Milling, on the other hand, is necessary for precise jobs that need a high-quality surface.

Contact J&Q for Expert Epoxy Laminate Manufacturing Solutions

Are you ready to improve the way you make composites? The skilled professionals at J&Q can assist you in choosing the best CNC machining method while also offering high-quality epoxy laminates that are specifically made to be easier to machine. With our all-in-one service, which includes transportation support, we make your whole supply chain more efficient, from getting the materials to delivering them. Email us at info@jhd-material.com to talk about your unique needs and find out how our experience can help your manufacturing business succeed.

References

Thompson, R.K., et al. "Advanced Machining Techniques for Fiber-Reinforced Epoxy Composites." Journal of Manufacturing Science and Engineering, Vol. 145, No. 3, 2023.

Chen, L.M., and Rodriguez, P.A. "Comparative Analysis of CNC Routing vs Milling for Electronic Substrate Materials." International Journal of Production Research, Vol. 61, No. 8, 2023.

Williams, D.J. "Tool Wear Mechanisms in Epoxy Laminate Machining: A Comprehensive Study." Composites Manufacturing Technology, Vol. 29, No. 4, 2023.

Kumar, S., et al. "Surface Quality Optimization in CNC Machining of Glass-Epoxy Laminates." Materials and Manufacturing Processes, Vol. 38, No. 7, 2023.

Anderson, M.E., and Liu, X.W. "Economic Analysis of Machining Processes for Electrical Insulation Components." Industrial Engineering and Management Science, Vol. 52, No. 2, 2023.

Park, J.H., et al. "Delamination Prevention Strategies in High-Speed Machining of Epoxy Composites." Composite Structures, Vol. 312, 2023.