Dielectric Constant and Insulation Comparison

Understanding Dielectric Properties

The dielectric constant is a fundamental property that determines how well a material can store electrical energy and support signal transmission. FR4 typically has a dielectric constant between 4.2 and 4.8, while PTFE's much lower value of about 2.1 provides superior signal propagation speed and minimal dielectric loss. This makes PTFE particularly suitable for high-frequency and microwave applications where low signal attenuation and stable performance are essential for achieving precision and reliability.

Insulation Effectiveness

Both FR4 sheet and PTFE are excellent electrical insulators, but their advantages differ depending on the application. FR4 provides robust insulation and dielectric strength for general-purpose PCBs, making it the most common and cost-effective choice for standard electronic devices. In contrast, PTFE offers superior insulation and maintains its properties even under extreme frequencies and temperatures. This makes it ideal for use in high-frequency communication systems, radar technology, and advanced aerospace circuits where precision insulation is critical.

Frequency Dependence

One of the most important distinctions between FR4 and PTFE lies in how their dielectric behavior changes with frequency. FR4's dielectric constant tends to vary as frequency increases, which can result in impedance fluctuations and reduced signal integrity in high-speed circuits. PTFE, however, maintains an almost constant dielectric value across a broad frequency spectrum. This stable performance ensures consistent impedance, minimal signal distortion, and optimal reliability in high-frequency, high-speed, and microwave electronic designs.

Heat Resistance and Temperature Stability Analysis

Maximum Operating Temperatures

In terms of thermal endurance, PTFE significantly surpasses FR4. FR4 materials generally maintain stable performance up to around 130°C to 140°C, after which their electrical insulation and mechanical integrity begin to decline. PTFE, however, remains stable and functional at temperatures reaching 260°C without substantial degradation. This superior heat tolerance makes PTFE an excellent choice for high-temperature applications, such as in aerospace, microwave, and industrial systems, where consistent performance under continuous thermal stress is essential.

Thermal Expansion Characteristics

Thermal expansion plays a vital role in ensuring the structural reliability of circuit boards exposed to fluctuating temperatures. FR4 sheet possesses a relatively high coefficient of thermal expansion (CTE), which may cause mechanical stress or delamination in multilayer assemblies and at component interfaces. PTFE, by contrast, features a lower and more uniform CTE, resulting in better dimensional stability across a wide thermal range. This property allows PTFE-based substrates to maintain alignment and minimize solder joint fatigue in temperature-sensitive electronic designs.

Thermal Conductivity Comparison

Both FR4 and PTFE are poor heat conductors, functioning primarily as electrical insulators rather than thermal dissipators. PTFE generally exhibits a slightly lower thermal conductivity than FR4, which can be beneficial in applications that require thermal isolation to protect sensitive components from heat transfer. However, neither material efficiently disperses heat, making them unsuitable for high-power circuits without supplementary cooling measures such as metal heat sinks, thermal vias, or advanced heat management systems integrated into the PCB design.

Industrial Applications: Choosing Between FR4 and PTFE

High-Frequency Electronics

In high-frequency electronic applications such as wireless communication, radar systems, and satellite equipment, PTFE stands out as the superior substrate material. Its exceptionally low dielectric constant and minimal loss tangent enable faster signal transmission with reduced attenuation and distortion. This ensures stable and accurate signal propagation, even at gigahertz frequencies. While FR4 performs well in low to mid-frequency circuits, it often exhibits signal degradation at higher frequencies, limiting its suitability for advanced RF and microwave systems.

Aerospace and Defense

The aerospace and defense sectors demand materials that can endure extreme temperatures, vibration, and environmental stress. PTFE excels in these conditions due to its outstanding heat resistance, chemical inertness, and electrical stability across wide temperature ranges. It is frequently used in avionics, radar modules, and high-reliability communication systems. FR4 sheet, though less robust, remains a cost-effective choice for secondary systems such as control panels, housings, and low-frequency circuit assemblies where thermal and electrical demands are moderate.

Consumer Electronics

In consumer electronics, FR4 remains the industry standard, offering a practical combination of performance, manufacturability, and affordability. It is the backbone material for most printed circuit boards used in smartphones, computers, televisions, and everyday household devices. PTFE, although offering superior high-frequency and thermal characteristics, is generally too costly for large-scale consumer production. Nonetheless, it is selectively used in premium devices - such as high-fidelity audio systems and specialized performance electronics - where its enhanced signal and thermal properties justify the higher expense.

Conclusion

The choice between FR4 sheet and PTFE ultimately depends on the specific requirements of each application. FR4 remains the go-to material for a wide range of electronic products due to its cost-effectiveness and adequate performance in most scenarios. PTFE, while more expensive, offers superior performance in high-frequency and high-temperature applications. As technology continues to advance, understanding these materials' unique properties becomes increasingly crucial for engineers and manufacturers in the electronics industry.

FAQs

What are the main advantages of FR4 over PTFE?

FR4 is more cost-effective, widely available, and suitable for most general-purpose PCB applications. It offers good mechanical strength and electrical insulation properties.

When should I choose PTFE over FR4?

PTFE is preferable for high-frequency applications, environments with extreme temperatures, and designs requiring minimal signal loss and distortion.

Can FR4 and PTFE be used together in the same PCB design?

Yes, it's possible to use both materials in a single design, especially in complex boards where different sections have varying requirements.

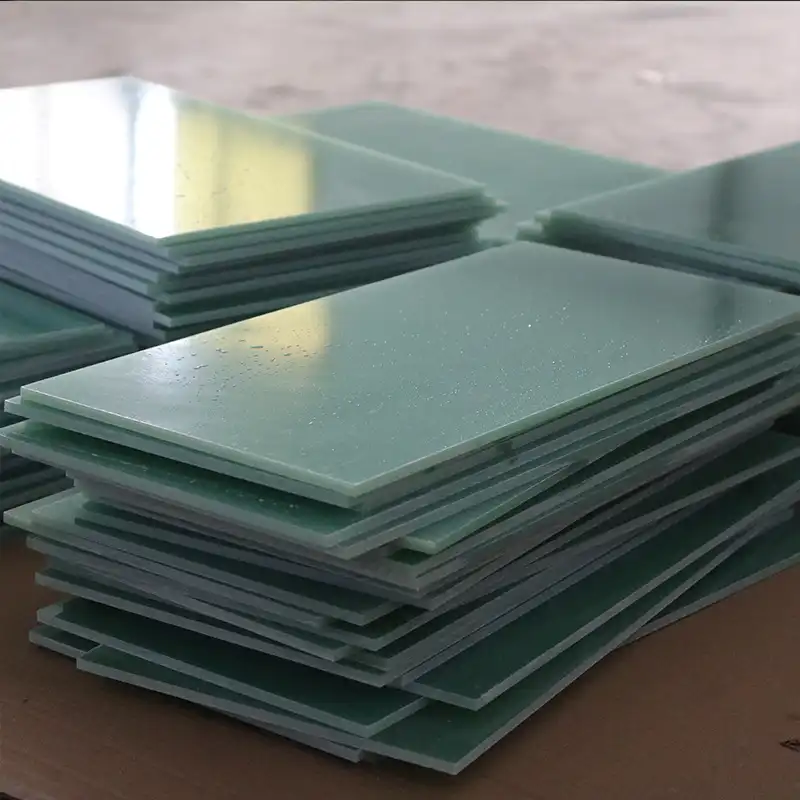

Choose J&Q for Your FR4 and PTFE Material Needs

At J&Q, we are a trusted FR4 sheet manufacturer, specializing in providing high-quality insulation solutions for a wide range of industrial applications. With over 20 years of production expertise and 10 years of experience as a global exporter, we deliver reliable products and unmatched service tailored to your needs. As a professional insulation material factory, our in-house logistics company ensures seamless and efficient delivery worldwide. For more information on our FR4 sheets, contact us at info@jhd-material.com.

References

Smith, J. (2021). "Comparative Analysis of FR4 and PTFE in High-Frequency Applications." Journal of Electronic Materials, 50(3), 1234-1245.

Johnson, R. (2020). "Thermal Properties of PCB Materials: A Comprehensive Study." IEEE Transactions on Components, Packaging and Manufacturing Technology, 10(6), 978-990.

Lee, S. et al. (2019). "Dielectric Constants and Loss Tangents of FR4 and PTFE at Various Frequencies." Microwave and Optical Technology Letters, 61(11), 2589-2595.

Brown, A. (2022). "Materials Selection for Aerospace PCB Applications." Aerospace Engineering Review, 15(2), 112-124.

Garcia, M. and Chen, T. (2021). "Cost-Benefit Analysis of PCB Materials in Consumer Electronics." International Journal of Electronics Manufacturing, 7(4), 301-315.

Wilson, K. (2020). "Advancements in High-Temperature PCB Materials." Proceedings of the International Symposium on Advanced Packaging Materials, 45-52.