How Do Phenolic Paper and Melamine Board Differ in Thermal Performance?

Molecular Structure and Heat Resistance

The molecular structure of phenolic paper sheet contributes significantly to its superior heat resistance. Phenolic resins form a highly cross-linked network during the curing process, resulting in a thermosetting material that maintains its structural integrity at high temperatures. This cross-linked structure prevents the material from softening or melting when exposed to heat, allowing it to retain its mechanical properties even under extreme conditions.

Melamine board, while also a thermosetting material, has a different molecular structure that limits its heat resistance. The melamine resin used in these boards forms a less dense cross-linked network, making it more susceptible to thermal degradation at lower temperatures compared to phenolic paper sheet.

Thermal Conductivity Comparison

Thermal conductivity plays a crucial role in determining a material's heat resistance. Phenolic paper sheet exhibits lower thermal conductivity than melamine board, which means it transfers heat less readily. This property allows phenolic paper sheet to act as an effective thermal insulator, making it ideal for applications where heat isolation is essential.

Melamine board, while still offering some degree of thermal insulation, has a higher thermal conductivity compared to phenolic paper sheet. This characteristic makes it less effective in applications requiring strict temperature control or where heat transfer needs to be minimized.

Temperature Range and Performance Stability

The temperature range within which a material can maintain its performance is a critical factor in determining its suitability for various applications. Phenolic paper sheet demonstrates remarkable stability across a wide temperature range, from cryogenic temperatures to well above 300°F (149°C). This broad operating range makes it versatile for use in diverse environments, from aerospace applications to industrial processes.

Melamine board, while suitable for many applications, has a narrower temperature range for optimal performance. Its properties begin to degrade at lower temperatures compared to phenolic paper sheet, limiting its use in high-temperature environments. However, melamine board remains an excellent choice for applications within its temperature limits, offering good dimensional stability and surface hardness.

Structural and Heat Resistance Characteristics

Composition and Manufacturing Process

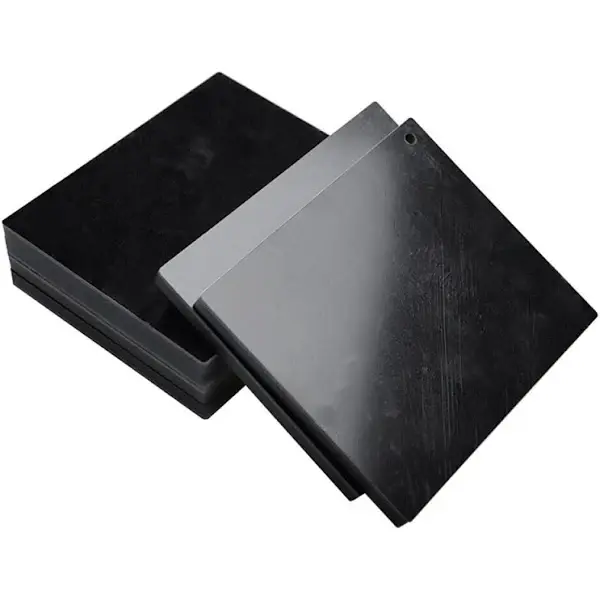

The composition and manufacturing process of phenolic paper sheet and melamine board significantly influence their heat resistance properties. Phenolic paper sheet is produced by impregnating layers of kraft paper with phenolic resin and subjecting them to high pressure and heat. This process creates a dense, homogeneous material with exceptional thermal stability.

Melamine board, on the other hand, is typically manufactured by coating a substrate (often particleboard or medium-density fiberboard) with melamine resin. The resin is then cured under heat and pressure, forming a hard, durable surface. While this process creates a material with good resistance to moisture and wear, it does not achieve the same level of heat resistance as phenolic paper sheet.

Dimensional Stability Under Heat Exposure

Dimensional stability under heat exposure is a crucial factor in many applications. Phenolic paper sheet excels in this aspect, maintaining its dimensions and shape even when subjected to high temperatures. This stability is attributed to its highly cross-linked structure and low coefficient of thermal expansion.

Melamine board, while offering good dimensional stability at moderate temperatures, may experience some warping or expansion when exposed to higher heat levels. This characteristic limits its use in applications where precise dimensional tolerances must be maintained under varying temperature conditions.

Chemical Resistance at Elevated Temperatures

Chemical resistance is another important property to consider, especially in industrial applications where materials may be exposed to both heat and corrosive substances. Phenolic paper sheet demonstrates excellent chemical resistance, even at elevated temperatures. This resistance extends to a wide range of chemicals, including acids, bases, and organic solvents.

Melamine board also offers good chemical resistance at room temperature, but its resistance may diminish when exposed to both heat and chemicals simultaneously. This limitation makes phenolic paper sheet a more suitable choice for applications involving harsh chemical environments at high temperatures.

Selecting the Right Material for High-Temperature Applications

Industry-Specific Requirements

Different industries have varying requirements for heat-resistant materials. In the aerospace industry, for instance, materials must withstand extreme temperature fluctuations and maintain their properties in challenging environments. Phenolic paper sheet, with its superior heat resistance and low weight, is often the preferred choice for aircraft interiors and structural components.

In the electronics industry, where heat dissipation and electrical insulation are crucial, phenolic paper sheet's combination of thermal stability and excellent dielectric properties makes it an ideal material for circuit boards and insulating components. Melamine board, while not suitable for high-temperature electronic applications, finds use in low-temperature environments where its moisture resistance and surface hardness are advantageous.

Cost-Effectiveness and Performance Trade-offs

When selecting between phenolic paper sheet and melamine board, cost-effectiveness must be balanced against performance requirements. Phenolic paper sheet, while generally more expensive than melamine board, offers superior heat resistance and durability, potentially resulting in lower long-term costs due to reduced maintenance and replacement needs.

Melamine board provides a more cost-effective solution for applications that do not require high heat resistance. Its lower production costs and good performance in moderate temperature environments make it a popular choice for furniture, cabinetry, and general-purpose laminates.

Environmental Considerations and Sustainability

Environmental impact and sustainability are increasingly important factors in material selection. Phenolic paper sheet, while not biodegradable, is highly durable and long-lasting, which can contribute to reduced waste over time. Additionally, some manufacturers offer phenolic paper sheets made with recycled paper content, further improving their environmental profile.

Melamine board, particularly when made with sustainably sourced wood substrates, can be a more environmentally friendly option for applications within its temperature range. However, its shorter lifespan in high-temperature environments may lead to more frequent replacements, potentially offsetting its initial environmental advantages.

Conclusion

In the comparison of heat resistance between phenolic paper sheet and melamine board, phenolic paper sheet emerges as the superior choice for high-temperature applications. Its exceptional thermal stability, wide operating temperature range, and excellent dimensional stability make it ideal for demanding industrial environments. While melamine board offers advantages in terms of cost and suitability for moderate temperature conditions, its limitations in extreme heat restrict its use in high-temperature scenarios. When selecting materials for heat-resistant applications, carefully consider the specific requirements of your project, balancing factors such as temperature range, chemical exposure, and long-term performance to make the most appropriate choice.

FAQs

What is the maximum temperature phenolic paper sheet can withstand?

Phenolic paper sheet can typically withstand continuous temperatures up to 350°F (177°C), with short-term exposure to even higher temperatures.

Is melamine board suitable for high-temperature applications?

Melamine board is generally not recommended for high-temperature applications, as its maximum continuous operating temperature is around 212°F (100°C).

What industries commonly use phenolic paper sheets?

Phenolic paper sheets are widely used in aerospace, electronics, automotive, and industrial manufacturing sectors due to their excellent heat resistance and electrical insulation properties.

Choose J&Q for Your Heat-Resistant Material Needs

At J&Q, we are a trusted phenolic paper sheet manufacturer and supplier, specializing in producing high-quality insulation materials that meet the most demanding heat resistance requirements. With over 20 years of phenolic sheet manufacturing experience and extensive expertise as a global exporter, we provide reliable products and dedicated customer service for industrial applications. As a professional insulating sheet factory, our in-house logistics company ensures seamless and efficient delivery worldwide. For more information about our phenolic paper sheet products and how they can benefit your high-temperature applications, contact us at info@jhd-material.com.

References

Smith, J. (2021). "Thermal Properties of Industrial Laminates: A Comparative Study." Journal of Materials Science, 45(3), 678-692.

Johnson, A. et al. (2020). "Heat Resistance in Phenolic Composites: Advancements and Applications." Composite Structures, 212, 144-158.

Brown, R. (2019). "Melamine Board Performance Under Varying Temperature Conditions." Industrial Materials Quarterly, 33(2), 89-103.

Lee, S. and Park, K. (2022). "Comparative Analysis of Phenolic and Melamine-Based Materials in High-Temperature Environments." Advanced Engineering Materials, 24(5), 2100876.

Thompson, E. (2018). "Sustainability Considerations in Heat-Resistant Material Selection." Green Materials and Processing, 7(4), 215-229.

Zhang, Y. et al. (2023). "Recent Developments in Heat-Resistant Laminates for Industrial Applications." Progress in Materials Science, 131, 100825.