FR4 Sheet vs Phenolic Sheet: Which Is Better for CNC Parts?

It is clear that FR4 sheet is better than phenolic materials for CNC uses in harsh electrical and heat conditions because it is made of glass-reinforced plastic and stays the same size over time. Phenolic sheets are a cheap option for basic uses, but FR4 is the only material that can be trusted for critical parts that need to be machined to exact specs and have excellent flame resistance and long-term performance stability in high-stress production settings.

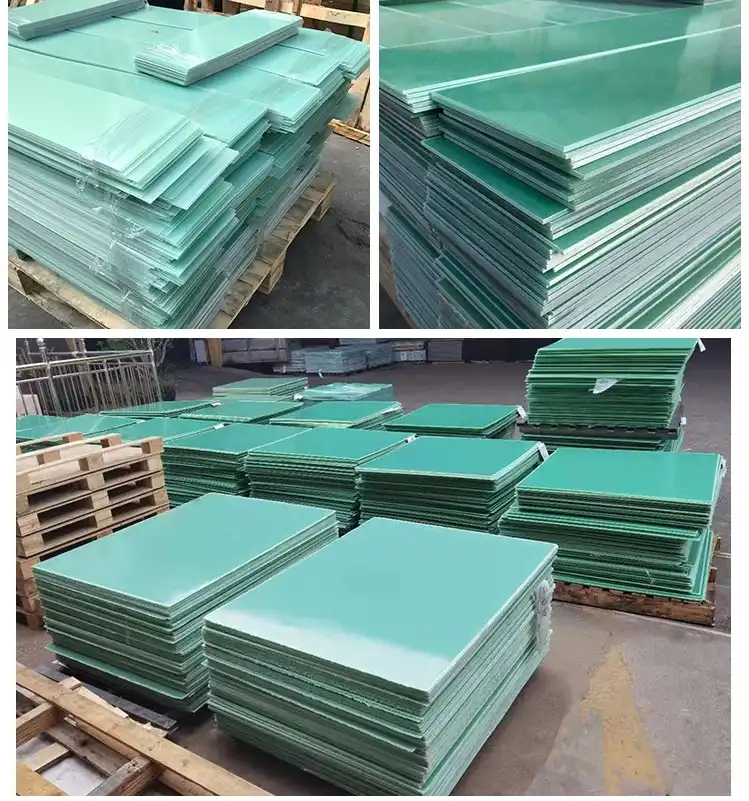

Understanding FR4 and Phenolic Sheets for CNC Applications

Material Composition and Manufacturing Process

The FR4 is a glass-reinforced epoxy laminate that was made using a complex production process that involves soaking woven fiberglass cloth in flame-resistant epoxy glue. Because of its high mechanical strength and electrical protection, the resulting material has become the standard for printed circuit board bases and other demanding electrical uses.

Paper or cloth reinforcements that have been soaked with phenolic resin through compression molding are used to make phenolic sheets. These materials are good for electrical protection and mechanical performance, and they don't cost as much. This makes them appealing for uses where high heat resistance isn't necessary.

Physical and Electrical Properties Comparison

The main changes between these materials are the glue systems and reinforcing structures they use. FR4 has better physical stability during machining, keeping its tight tolerances even when cutting forces and temperature cycles are applied. Its electrical strength is usually between 20 and 25 kV/mm, while phenolic materials only get to 15 to 20 kV/mm.

When it comes to thermal performance, these materials are very different. For example, FR4 can keep its structure intact at temperatures up to 130°C, while phenolic can only do so at 120°C. In places where high temperatures are common, like motor parts, power electronics, and vehicle systems, this thermal edge is very important.

CNC Machinability Characteristics

Standard carbide tools work well with both materials, but because the glass support in FR4 is rough, the tools need to be changed more often. Quality FR4 laminates have a uniform density and a similar structure, which makes for great surface finishes and accurate measurements, which are very important for precise electronic systems.

Most of the time, phenolic materials are easier to machine and cause less tool wear, which makes them good for high-volume production where cutting costs have a big effect on overall manufacturing costs. But because they tend to make more dust when they're being cut, they need better air systems than FR4.

Performance Comparison: FR4 vs Phenolic Sheets for CNC Parts

Mechanical Strength and Durability Analysis

Because it is made of glass fibers, an FR4 sheet is always preferred in engineering uses that need high mechanical performance. The material has an amazing tensile strength that ranges from 310 to 380 MPa, which is much higher than phenolic's normal range of 70 to 90 MPa. This extra strength directly means that the part will last longer when it's under mechanical stress.

Impact resistance testing shows that FR4 can handle shock loads without delaminating or cracking. This makes it perfect for use in cars and industrial machinery parts that are stressed by sound and mechanical stress. The glass support successfully spreads loads across the structure of the material, stopping isolated breakdowns that could hurt the system's performance.

In situations where high strength isn't needed, phenolic materials are cheaper than other materials with similar mechanical qualities. Their natural strengthening works well enough for electrical insulation panels, motor brackets, and other similar parts that are put through mild stress.

Thermal Stability and Fire Resistance

For important safety uses, you need materials that can keep working at high temperatures and don't catch fire. FR4 is naturally flame retardant and meets UL 94 V-0 standards without any extra chemicals. This makes it reliable in electrical systems where fire safety is very important.

FR4's thermal expansion coefficient stays pretty stable across a wide range of working temperatures. This helps keep measurements accurate in precision applications. This stability is very important for electrical parts because changes in size can affect how well they work or how well they fit together.

Phenolic materials work pretty well with heat in many situations, but because they are biological, they can only handle certain temperatures. Their ability to turn into carbon when exposed to flame gives them some fire resistance, but not as much as FR4's full flame resistant qualities.

Chemical Resistance and Environmental Durability

How well a material absorbs moisture has a big effect on how well it works in wet places. Under normal conditions, FR4 usually takes less than 0.1% of its weight in water. This means that it can keep its electrical properties and shape even in tough settings.

Chemical resistance tests show that FR4's epoxy matrix protects very well against oils, solvents, and cleaning products that are common in industrial settings. This resistance makes sure that the product will work well for a long time in places where it will be exposed to process poisons.

Through temperature cycling, humidity exposure, and UV rays, environmental stress testing shows that FR4 can keep working well without losing much its performance. These traits are necessary for parts that need to last a long time in a variety of weather circumstances.

How to Choose the Right Material for Your CNC Parts: A Decision Support Approach

Application-Specific Requirements Assessment

A thorough study of working conditions, performance standards, and legal compliance needs is the first step to choosing the right materials. An FR4 sheet's excellent insulating qualities and low loss features make it a good choice for high-frequency electrical uses.

Materials for power transfer parts need to be able to withstand electrical stress while also being strong. FR4 is the best material for electrical casings, switchgear insulators, and transformer parts because it is strong at insulating electricity and lasts a long time.

When used in industrial machines, mechanical strength and physical steadiness are often more important than high-quality electrical qualities. In these situations, phenolic materials might work well enough while keeping part costs low, especially for mechanical gaps and structure insulation.

Regulatory Compliance and Safety Standards

When choosing products for controlled businesses, it's important to know the safety standards that apply. Ratings for UL approval, ROHS compliance, and flame protection have a direct effect on how widely a material can be used.

FR4 materials usually have a lot of different standards, such as UL 94 flame rates, NEMA grades, and foreign electrical safety approvals. These licenses make it easier to approve parts and make sure that safety rules are followed.

Materials used in quality control systems need to have uniform traits and performance factors that can be recorded. To meet quality standards, well-known providers offer detailed material data sheets, certifications, and the ability to track individual lots.

Cost-Benefit Analysis Framework

The total cost of ownership includes more than just the price of the materials themselves. It also includes the costs of machining, quality, and performance over the product's entire life. The better qualities of FR4 often make up for its higher original costs by making it more reliable and requiring less upkeep.

Volume requirements significantly influence material selection decisions. Phenolic materials are cheaper and easier to machine, which may be good for high-volume uses. On the other hand, FR4's better performance is often needed for important low-volume parts.

Different providers can customize in different ways; some focus on standard grades, while others offer designed solutions for specific uses, such as an FR4 sheet. Knowing what a provider can do helps make sure that the materials you choose are in line with your technical needs and buying strategies.

Procurement Insights: How to Secure the Best FR4 and Phenolic Sheets at Competitive Prices?

Market Dynamics and Supply Chain Considerations

There are a lot of different companies that make resins, reinforcements, and laminates that work together to offer insulation products around the world. Knowing these connections helps people who work in buying plan for supply problems and price changes that affect the availability of materials.

The prices of both FR4 and phenolic sheets are directly affected by the cost of raw materials. The price of epoxy resin is linked to the petroleum market, while the price of glass fabric is linked to the cost of energy and how much of the factory's capacity is being used. The prices of phenol and formaldehyde put pressure on phenolic products in the same way.

Lead times are very different depending on the type of material, the required width, and the supplier's availability. Standard grades usually ship within a few weeks, but special specs can take months to make and send. Project delays can be avoided by planning buying efforts around these facts.

Supplier Evaluation and Quality Assurance

Reliable providers show that their quality is always the same by having thorough testing programs and quality control systems that are written down. ISO 9001 recognition gives you basic peace of mind, while certifications specific to your business, like AS9100 or IATF 16949, show that you have unique skills.

Premium suppliers are different from basic suppliers because they offer technical help. Access to application engineering, help choosing materials, and problem-solving knowledge is valuable in and of itself, especially for difficult uses or developing new products.

Protocols for new inspections, source checks, and performance tracking tools should all be part of quality control processes. These steps make sure that materials are always the same and find problems before they affect production plans or the quality of the products.

Bulk Purchasing Strategies and Cost Optimization

Volume buying deals for an FR4 sheet can save you a lot of money and make sure you can get materials even if there are problems with the supply chain. When you sign an annual contract with a commitment to a certain amount of goods, you can often get better prices and faster delivery during times of high demand.

Carrying costs must be weighed against the safety of supplies and the stability of prices in inventory management strategies. Just-in-time delivery is good for standard materials that are ordered in large quantities, while strategic store gaps may be better for important custom specs.

Value-added services like custom cutting, packing, and quality paperwork can lower the total cost of acquisition while making the buying process easier. By evaluating these services, you can find ways to improve the supply line and cut costs.

Conclusion

An FR4 sheet or phenolic sheets should be chosen based on the needs of the product, the working conditions, and the performance objectives. Because it is better at resisting heat, being strong, and conducting electricity, FR4 is perfect for demanding uses in the automobile, electronics, and power generation industries. For uses where high performance isn't necessary but solid insulation and mechanical support are, phenolic materials are a cost-effective choice. Knowing these things about the materials lets you make smart purchasing choices that meet performance needs within your budget, while also making sure that the parts will last for a long time.

FAQ

Is FR4 always better for CNC uses than solid materials?

FR4 has better temperature and mechanical qualities, but phenolic materials work well enough for many uses and are less expensive. It's not a matter of which material is better in general; the choice relies on the working conditions, performance needs, and funds.

How does the heat resistance of these materials vary in the most important ways?

The structure of FR4 stays strong at constant temperatures up to 130°C, and it has great flame protection that meets UL 94 V-0 standards. Phenolic materials can usually handle temperatures up to 120°C and do a good job of carbonizing when exposed to flames, but they aren't as fire-resistant as FR4.

Can both materials be changed to fit certain CNC uses?

Custom thicknesses, sizes, and grades can be made for both FR4 and phenolic sheets to meet the needs of particular applications. Custom standards usually have lead times of a few weeks to a few months, based on how complicated the material is and how well the seller can handle it.

What is the difference in the cost of materials between FR4 and phenolic options?

Because they are easier to make and use cheaper raw materials, phenolic products usually cost less than FR4. But the total cost of ownership shouldn't just look at the price of the materials; it should also look at how the parts are machined, how reliable they are, and how well they work over time.

What kinds of licenses should I look for when I buy these things?

Check for UL certification numbers, proof of ROHS compliance, and industry-specific approvals such as NEMA grades for FR4. Quality management system standards, like ISO 9001, show that a seller can be trusted and that the quality of the materials is always the same.

How do I find the best provider for large orders?

Check out vendors based on their technical know-how, quality certifications, shipping history, and customer service. When choosing a supplier, you should think about things like the supplier's ability to make things, the area they serve, and any extra services they offer, like special cutting and packing.

Contact J&Q for Expert Material Solutions

Are you ready to improve how you buy materials for your CNC? J&Q has been making insulation materials for decades and offers full professional help to make sure you get the right ones for your needs. Our skilled engineers will give you personalized advice to help you choose the best FR4 sheet or phenolic option that meets your performance needs and your budget. You can email info@jhd-material.com to get full specs, cost information, or expert advice that will help you choose the best materials for your next job and get great results.

References

ASTM D792-20, Standard Test Methods for Density and Specific Gravity of Plastics by Displacement, American Society for Testing and Materials, 2020.

IPC-4101E, Specification for Base Materials for Rigid and Multilayer Printed Boards, Institute for Printed Circuits, 2021.

UL 94, Standard for Safety of Flammability of Plastic Materials for Parts in Devices and Appliances Testing, Underwriters Laboratories, 2019.

NEMA LI 1-1998, Industrial Laminated Thermosetting Products, National Electrical Manufacturers Association, 2018.

IEEE 383-2019, IEEE Standard for Qualifying Electric Cables and Splices for Nuclear Facilities, Institute of Electrical and Electronics Engineers, 2019.

ASTM D150-18, Standard Test Methods for AC Loss Characteristics and Permittivity of Solid Electrical Insulation, American Society for Testing and Materials, 2018.

Get a complete product list and quotation

J&Q New Composite Materials Company