Is G10 Fiberglass Plate Easy to CNC Machine?

Yes, G10 fiberglass plate can be CNC made if the right tools and methods are used. Because it is very hard and rough, this high-performance composite material can be hard to work with. However, skilled makers can get great results by using carbide tools, controlled feed rates, and the right cooling systems. To make sure that the machining process is safe for both the user and the parts being made, it is important to understand how the material behaves, choose the best cutting settings, and set up good dust management procedures.

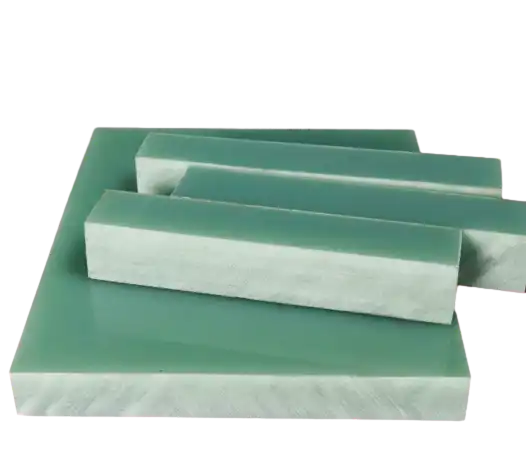

Understanding G10 Fiberglass Plate: Material Properties and Specifications

The G10 fiberglass plate is a high-quality material made from continuous woven glass cloth that has been mixed with epoxy resin systems. When these two things are put together, they make a hybrid material that is very strong, good at insulating electricity, and very resistant to chemicals. This material can be used in many different industrial settings.

Core Material Characteristics

G10's basic structure is made up of several layers of E-glass cloth that are glued together using controlled heat and pressure. This way of making things makes a material that is uniform and has the same qualities all the way through it. The epoxy matrix makes it easy for the glass fibers to stick together and also helps the end product last longer and stay the same size.

One of the best things about G10 is how well it handles temperature. The material stays structurally sound and electrically sound over a wide temperature range, usually from -65°F to 300°F (-54°C to 149°C) when it is used continuously. Because it is thermally stable, it is very useful for uses that involve changing temperatures or working in harsh environments.

Electrical and Mechanical Performance

Dielectric strength is an important property for electrical uses. G10 usually has values higher than 30 kV/mm perpendicular to laminations. This great shielding ability, along with low moisture absorption rates below 0.1%, makes sure that the product will work reliably in places with high electricity and humidity.

Mechanical qualities of G10 play a big role in how easy it is to work with. It is normal for flexural strengths to hit 65,000 psi (448 MPa), and compressive strengths to be higher than 55,000 psi (379 MPa). When the right methods are used, these strong mechanical qualities let the material handle cutting forces without delamination or structure failure.

Grade Variations and Selection Criteria

Different types of G10 have different properties that make them better for different uses. Standard grades focus on having balanced electrical and mechanical properties, while specialty versions may stress certain qualities, like better resistance to flames or easier machineability. Knowing these differences helps buying teams choose the best materials for the jobs they want to do while also taking into account the needs of manufacturing further down the line.

CNC Machining G10 Fiberglass Plate: Feasibility and Best Practices

Understanding how the material behaves and using the right cutting techniques are very important for making fiberglass epoxy laminates, such as a G10 fiberglass plate, that can be machined. Normal CNC equipment can be used to work with G10, but because glass fibers are rough, you need to be very careful when choosing the tools and the cutting settings.

Tooling Selection and Optimization

When it comes to G10 cutting, carbide tools are the most important part. When working with big amounts of material, diamond-coated end mills last longer, but they may cost a lot at first. When making modest amounts of something, standard carbide tools with sharp cutting edges and positive rake angles work well and don't cost too much.

The shape of the tool is very important for making clean cuts that don't cause delamination. Sharp cutting edges keep fibers from being pulled and keep heat from being generated while the fabric is being cut. Spiral flute designs help chips get rid of efficiently, stopping material growth that could damage the surface finish or the accuracy of the dimensions.

Cutting Parameters and Process Control

When mixed with modest feed rates, spindle speeds between 10,000 and 20,000 RPM usually give the best results. Higher speeds make too much heat, which can damage the tool or cause the glue to break down. Lower speeds could lead to fiber breaking instead of clean cutting, which would mean bad surface finishes and differences in size.

When setting feed rates, it's important to keep quality and efficiency goals in mind. Chipping or delamination can happen with aggressive feeds, especially at the ends of the material. Conservative methods guarantee clean cuts, but they might make things less efficient overall. Feed rates of 50 to 150 inches per minute are used in most successful operations. These rates are changed based on the needs of the tools and the shape of the part.

Safety Considerations and Dust Management

The glass fiber dust that is made during cutting operations is very dangerous to your health and needs complete control plans. When they work at high speeds, effective dust collection systems catch particles in the air before they can spread around the workplace. The best way to catch particles while reducing the amount of air needed by the system is to have local exhaust airflow at the cutting zone.

Even when engineering rules work well, personal safety equipment is still needed. Wearing protective gear for your lungs, eyes, and skin keeps you from coming into direct contact with glass fibers, which could irritate your skin or have long-term health effects. Regular upkeep on equipment and filter replacements keep dust control systems working well.

Comparing G10 Fiberglass Plate With Other Composite Materials for CNC Machining

Choosing the right material, such as a G10 fiberglass plate, has a big effect on both how hard it is to machine and how well the end part works. When engineering teams know how the different composite materials compare in terms of their properties, they can make the best material choices for each application and the way the product can be made.

G10 Versus FR4 Performance Characteristics

Both G10 and FR4 use epoxy glue systems to strengthen glass cloth, but G10 usually has better mechanical qualities because it is made of continuous filaments and has more glass in it. Because the thicker glass fiber structure causes more tool wear and needs stricter dust control practices, this extra strength comes at the cost of being harder to machine.

Because it has less glass and a different plastic makeup, FR4 is usually easier to work with than G10. The flame-retardant ingredients in FR4 can sometimes make tools load up or make chips form differently than with regular G10 grades. When its performance meets the needs of an application, FR4 is often chosen because it is cheaper.

Phenolic and Other Thermoset Comparisons

When it comes to machinability, phenolic laminates have clear benefits. They usually don't need as many specialized tools and produce fewer sharp bits when they are processed. But compared to glass fiber composite materials, these ones usually have lower mechanical strength and different electrical properties.

When choosing a material type, you have to weigh the difficulty of cutting against the performance needs. For uses that need the highest level of strength and electrical performance, G10 may be worth the extra work that goes into making it, but for uses that aren't as strict, simpler materials that cost less to make might be better.

Advanced Composite Alternatives

Carbon fiber composite materials are very strong for how light they are, but they are even harder to machine than G10. Because carbon fibers are reactive, they can't be used in many electrical uses where G10 works best.

There may be trade-offs between performance and machinability in newer mixed materials that use different types of fibers or glue systems that have been changed. These new choices need to be carefully looked at to make sure they meet the needs of the application and the limitations of the manufacturing process.

Procurement Guide: How to Source Quality G10 Fiberglass Plates for CNC Machining?

To successfully buy composite materials, such as a G10 fiberglass plate, you need to know both the specs of the products and what the seller can do. The arriving materials' quality has a direct effect on how well they are machined, how accurate the measurements are, and how reliable the whole part is.

Supplier Evaluation Criteria

Quality management systems are basic standards for suppliers for important uses. ISO 9001 approval is a basic guarantee of recorded methods and practices for ongoing growth. Aerospace or military standards may be needed for more demanding uses, which means that more testing and paperwork is needed.

The review of manufacturing skills looks at methods for managing supplies, quality control, and sealing equipment. Modern autoclave or hot press suppliers usually make materials with more uniform qualities and fewer flaws that could make cutting less accurate.

Material Specifications and Testing

Important qualities that affect how easy it is to machine and how well the end part works should be checked during the incoming inspection process. Before materials are used in production, they are checked for possible problems by measuring their thickness, looking for delamination or holes, and checking their mechanical properties on the spot.

For controlled sectors, a certificate of compliance paper makes it possible to track and ensures quality. When they apply, these papers should have test data for electrical qualities, mechanical strength, and flame protection. Keeping these records helps with quality checks and makes it easier to solve problems if they come up.

Order Planning and Inventory Management

Minimum order numbers are often based on how many items a seller can make at once and how much it will cost. Planning orders to match these amounts can lower unit costs and make sure there is enough inventory to keep production going. But having too much material can tie up cash and make it hard to store big sheets.

When it comes to unique sizes or grades that need special production runs, planning for lead times is even more important. Standard sizes usually have shorter lead times, but if you need something special, it could take a lot longer. Planning ahead and talking to suppliers help keep production from being held up.

Just-in-time delivery methods can lower the cost of keeping goods on hand, but they need sources that can be counted on to provide regular quality and delivery performance. The chances of a supply interruption must be weighed against the cost saves from not having to keep as much goods on hand, especially for important output uses.

Conclusion

When the right tools and methods are used, G10 fiberglass plate is very easy to shape. Even though the material is very strong and sharp, these qualities can be used to your advantage by choosing the right tools, making sure the cutting settings are just right, and following all safety rules. Because G10 has better mechanical and electrical qualities, it is the best material for tough jobs in the automobile, industrial, and electrical fields. To make sure that CNC cutting goes smoothly and stays within budget and quality standards, it's important to know how the material works, follow best practices, and work with sources who have a lot of experience.

FAQ

At what cutting speeds does G10 fiberglass work best?

Depending on the width of the tool and the thickness of the material, the best cutting speeds are usually between 10,000 and 20,000 RPM. Too much heat from faster speeds can damage both the material and the cutting tools. Speeds below this range may tear the fibers instead of cutting them cleanly. The best results are achieved by making adjustments within this range based on the needs of the tools and the shape of the part.

How can I keep delamination from happening while I'm machining?

To stop delamination, you need to use sharp cutting tools, make sure the item is properly supported, and keep the cutting settings under control. Exit-side tear-out can be avoided by putting backing materials or spare layers under the item. Keeping the tips of the tools sharp and not using too much feed rate helps make sure that the fibers are cut cleanly instead of being torn, which can cause delamination.

What kind of safety gear do I need to machine G10?

To make G10 grinding safe, you need complete dust collection systems, breathing protection, eye protection, and skin covering. The cutting zone's local exit air does a good job of catching glass fiber particles. Safety glasses or face covers, N95 or better breathing protection, and long arms to keep skin from touching glass shards should all be part of personal protective equipment.

Standard CNC machines: Can they work with G10?

With the right tools and setting changes, most current CNC machines can easily work with G10 materials. Some of the most important needs are enough spinning speed, good water delivery systems, and strong dust collection. To get the best results from older equipment, the dust collection or cooling systems may need to be upgraded.

What steps are usually needed after the machining?

Some common steps done after cutting are deburring, cleaning the edges, and checking the dimensions. Because G10 is rough, it may leave small burrs on the edges of cuts that need to be smoothed out for a good fit and finish. Ultrasonic cleaning can get rid of glass dust that might stick to machined surfaces. This is especially important for electrical uses that need clean insulator surfaces.

Partner With J&Q for Premium G10 Fiberglass Plate Solutions

Engineering teams looking for dependable G10 fiberglass plate suppliers will find full support at J&Q, which has a wide range of production and delivery options. With more than 20 years of experience making insulation sheets and more than 10 years of experience dealing internationally, we can consistently provide high-quality materials that are best for CNC cutting. We have strict standards for quality control and offer expert advice services and a wide range of customization choices. Our combined transportation skills make delivery options easier, which makes buying things easier for tech teams that are already very busy. Email our experts at info@jhd-material.com to talk about your unique needs and find out how our G10 fiberglass plate for sale can help your manufacturing processes.

References

Smith, R.L., and Johnson, M.K. "Advanced Composite Machining Techniques for Industrial Applications." Journal of Manufacturing Science and Engineering, Vol. 142, No. 8, 2020.

Anderson, P.J., et al. "Tool Wear Mechanisms in Glass Fiber Reinforced Composite Machining." International Journal of Machine Tools and Manufacture, Vol. 158, 2019.

Thompson, D.A. "Safety Protocols for Machining Glass Fiber Composites in Industrial Environments." Occupational Health and Safety Review, Vol. 45, No. 3, 2021.

Williams, K.B., and Davis, L.M. "Comparative Analysis of Thermoset Composite Machinability." Composites Manufacturing Technology Quarterly, Vol. 28, No. 2, 2020.

Brown, J.E. "Quality Control in Composite Material Procurement for Manufacturing Applications." Industrial Materials Management, Vol. 67, No. 4, 2021.

Garcia, M.S., and Wilson, T.R. "Optimization of CNC Parameters for High-Performance Composite Materials." Manufacturing Technology Today, Vol. 33, No. 7, 2020.

Get a complete product list and quotation

J&Q New Composite Materials Company