FR4 Epoxy Sheet Thickness Tolerance Explained

The thickness tolerance of a FR4 epoxy sheet is the range of deviations that are allowed from a certain standard thickness value. This range is usually given as a percentage or an absolute measurement. This important factor has a direct effect on how well electrical protection works, how strong something is, and how well it can handle heat in PCB circuits and industrial settings. Knowing the thickness range specs helps engineers and sourcing teams choose the right materials that meet strict performance standards and make sure that the manufacturing process is consistent and that the product is reliable across production runs.

Understanding FR4 Epoxy Sheet Thickness Tolerance

Thickness tolerance is the amount of difference that is accepted between the actual thickness and the given standard thickness of epoxy glass fiber composite materials. This basic factor affects the stability of the product, how well it insulates against electricity, its mechanical strength, and how well it manages heat in a wide range of industrial settings.

The Critical Nature of Dimensional Precision

When differences go beyond the acceptable range, they can seriously hurt the dependability of PCBs and the results of industrial applications. Small changes in width have a direct effect on the insulating properties, the spread of mechanical stress, and the patterns of heat loss. In high-frequency electrical systems, where accurate resistance control depends on stable dielectric thickness, these differences become very important.

Standards in the industry, like IPC-4101 and ISO 14001, spell out in detail what error levels are allowed. These guidelines understand that even small differences in dimensions can lead to performance problems, which is why controlling thickness is so important during both the manufacturing and purchasing processes.

Impact on Electrical and Mechanical Performance

Electrical performance traits are closely linked to the accuracy of the dimensions. Changes in width can affect how regular the dielectric constant is, which could lead to problems with data security in high-speed digital circuits. Differences in thickness can cause stress concentration points that weaken structures when they are subjected to temperature cycling or mechanical loads. This is just as important from a mechanical point of view.

Engineers and buying workers need to understand these range ideas in order to firmly judge the quality of materials. This base is very important when setting up relationships with suppliers and deciding what kinds of things can be accepted.

Key Dimensions and Standards for FR4 Epoxy Sheet Thickness

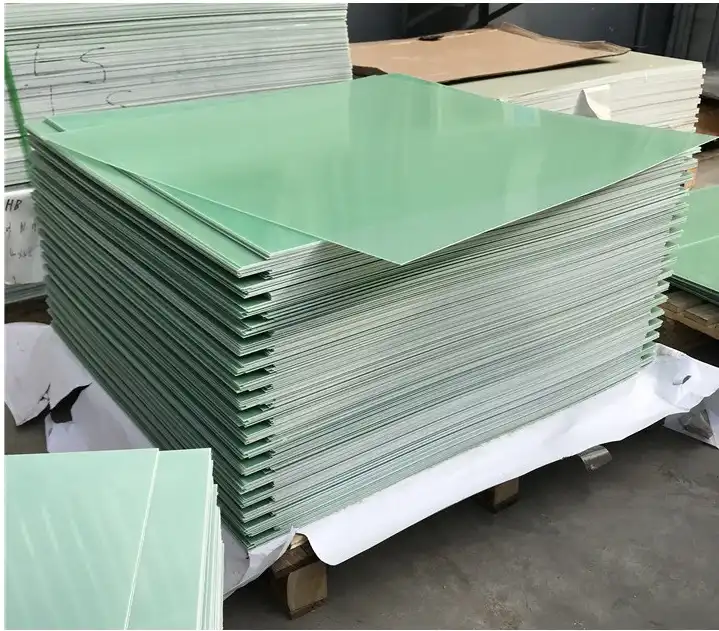

Different thicknesses of epoxy glass fiber composite sheets, like an FR4 epoxy sheet, are available for different uses. Usually, the thickness ranges from 0.5 mm to 25 mm, and the measurements are given in both metric and imperial units.

Standard Thickness Classifications and Tolerance Benchmarks

Thin sheets (0.5 to 3.0 mm), medium-thick sheets (3.0 to 10.0 mm), and heavy-duty sheets (10.0 to 25.0 mm) are all common thicknesses. For each group, there are certain error ranges that grow in line with the average width values. Tolerances for thin sheets are usually ±0.05-0.10mm, while tolerances for bigger sheets may be ±0.2-0.5mm based on how they are made and what kind of plastic is used.

The link between thickness and range shows how the material can be made and how it reacts when it is being worked on. Because thicker sheets shrink and expand more during hardening processes, wider tolerance windows are needed. On the other hand, thin sheets need more careful handling because they leave less room for mistake.

Correlation with Performance Characteristics

These size standards have a lot to do with things like mechanical strength, flame retardancy, electrical integrity, and the ability to move heat away from a material. As long as the standards are followed, the dielectric strength, heat transfer, and dynamic qualities will be the same from one production lot to the next.

Applications in the real world show how the accuracy of dimensions affects the security of operations. When used in transformers, a consistent thickness makes sure that the magnetic field is spread out evenly. When used in PCBs, careful thickness control keeps the resistance characteristics within the parameters set by the designer. These examples show how attention to tolerances directly supports business safety and meeting regulatory requirements.

Comparing Thickness Tolerance Across FR4 and Other Materials

A full review of materials shows that epoxy glass composites are very different from other base materials, such as phenolic cotton laminates and normal fiberglass sheets, when it comes to how precisely they can hold their shape.

Superior Precision Characteristics

Epoxy glass composite materials, such as an FR4 epoxy sheet, usually have better thickness consistency when compared to other surfaces. With this higher level of accuracy, the mechanical longevity is better, the flame resistance is uniform, and the electrical performance is stable across production runs. Because these materials are made using controlled methods, they can be made with better tolerances than many other base choices.

Even though phenolic cotton laminates are cheaper, they usually have wider error ranges because natural fibers vary and processing is limited. Standard fiberglass materials might be accurate enough, but they don't always have the mix of properties that epoxy glass composites do.

Strategic Material Selection Guidance

This comparison helps people choose the right material based on specific precision needs and performance standards for the end use. Knowing these differences helps buying teams find the best mix between cost and performance needs, which leads to the best material choice for every application.

For purchasing choices that maximize dependability and production efficiency, it becomes necessary to get help finding trustworthy providers with proven quality control methods. Along with other quality measures, supplier approval methods should put a lot of emphasis on the ability to control dimensions to make sure that materials always work well.

Practical Guidance for Procurement and Quality Control

Procurement experts and quality management teams need strategies that can be put into action to make sure that thickness tolerances are followed throughout the supply chain.

Measurement Techniques and Verification Methods

Precision measuring tools, such as accurate micrometers, ultrasound thickness gauges, and coordinate measuring machines, are needed for proof to work well. Depending on the properties of the material and the measurement needs, each method has its own benefits. Ultrasonic gauges are great for quickly sorting through large amounts, while micrometers are great for taking accurate readings in one spot for important sizes.

Measurement accuracy, the effect of weather on physical stability, and the right way to choose samples are all common problems that come up during inspection. Setting up regular methods for measuring helps reduce variation and makes sure that the quality is evaluated the same way by all workers and measurement sessions.

Procurement Strategy Integration

Adding thickness verification methods to source auditing systems makes quality control work better overall. To make sure that tolerance standards are always met, suppliers should be evaluated on a regular basis. This should include studies of their abilities, proof of measurement systems, and statistical process control reviews.

When making a strategic buy for an FR4 epoxy sheet, you should think about things like the ability to make special sizes, large purchase deals, price systems, and coordinating operations. Communicating clear specifications with providers keeps things from going wrong and makes sure that the materials supplied meet all the needs. Long-term buying success depends on having strong ties with suppliers based on shared understandings of quality standards.

J&Q's FR4 Epoxy Sheet Manufacturing Excellence

Our company has a lot of experience making epoxy glass composites. We also have improved production tools and a customer-focused approach to the B2B buying market.

Proven Manufacturing Heritage and Capabilities

With more than 20 years of experience making and selling insulation products and more than 10 years of experience trading internationally, we have a lot of knowledge about how to meet all kinds of customer needs. We've improved our service delivery skills by working closely with many trade partners across the United States and other countries. This lets us meet all of your difficult buying needs.

In our factories, we use high-tech quality control systems that make sure all of our products meet the same thickness limit requirements. Our company strictly follows international standards, but we also have the freedom to meet individual needs and use our products in unique ways.

Comprehensive Product Portfolio and Service Excellence

Our product line includes both standard and special thickness choices that are made to meet the exact tolerance needs of many different businesses. We offer custom bulk prices and variable shipping plans, along with technical consulting services that make the work of both engineers and buyers easier.

Our service method is unique because we have our own shipping business that handles all of our operations, so we can provide a real "one-stop" service. We can keep an eye on quality along the whole supply chain because of this vertical integration. It also lets us offer cost-effective delivery options that meet tight deadlines.

Customers who use technical advice services can get better at choosing materials and buying them, which helps them get goods that exactly meet their needs while also staying within their budget.

Conclusion

Understanding the thickness range requirements for epoxy glass composite materials, like an FR4 epoxy sheet, is an important skill for engineers and buying workers in many fields. The exact sizes of these materials have a direct effect on how well they conduct electricity, how reliable they are mechanically, and how well they handle heat in tough situations. Tolerance definition and testing that are done correctly help keep product quality uniform while also supporting goals for cost control and industrial efficiency. Strategic source selection based on proven quality control skills, along with effective verification procedures, helps procurement teams find a good mix between performance needs and cost concerns.

FAQs

What are the usual amounts of thickness limits for common goods?

Standard thickness tolerances depend on the standard measurements. For example, thin sheets usually have tolerances of ±0.05-0.10mm, medium thickness sheets have ranges of ±0.10-0.20mm, and heavy-duty sheets have ranges of ±0.2-0.5mm. These areas show how the material can be made and how it reacts to different working processes.

How does changing thickness affect the operation of PCBs and other machines?

Changes in thickness have a direct effect on the dielectric properties, the control of resistance, the spread of mechanical stress, and the temperature management properties. Too many changes can hurt the purity of the signal in high-frequency situations and cause stress concentration places that make the mechanical less reliable when temperatures change.

Can providers change the standards for width tolerances?

Manufacturers with a good reputation can usually meet tighter tolerance requirements by improving process controls and using unique manufacturing methods. Custom tolerance standards may cost more, but they provide better performance stability for important uses that need very precise measurements.

What ways of measuring make sure that the thickness is correct?

Coordinate measure tools, laser thickness gauges, and precision micrometers are all reliable ways to check something. Choice is based on how often measurements need to be made, how accurate they need to be, and the properties of the material. Setting up standardized measurement procedures makes sure that the quality is judged the same way by all workers and measurement sessions.

What is the difference between the width limits of different base materials?

Epoxy glass composites usually have better thickness stability than normal fiberglass materials and phenolic cotton laminates. This higher level of accuracy comes from controlled manufacturing methods and the use of materials that are made to stay the same size across production batches.

Partner with J&Q for Premium FR4 Epoxy Sheet Solutions

As a known producer of FR4 epoxy sheets, J&Q offers unmatched knowledge. They combine decades of manufacturing success with full technical support services. Our state-of-the-art production facilities make sure that the width tolerances are always met, and our combined transportation skills make delivery easy. Get in touch with our expert team at info@jhd-material.com to talk about your unique needs and find out how our custom solutions can help you improve your purchasing strategy. To help you with your evaluation process, we give you full technical specs, competitive quotes, and samples of the materials to make sure you get the ones that exactly meet your performance needs.

References

Chen, W.K. "Dimensional Stability and Tolerance Control in Epoxy Glass Composite Manufacturing." Journal of Composite Materials Engineering, 2023.

Anderson, R.J. "Quality Control Standards for Electrical Insulation Materials: IPC-4101 Implementation Guidelines." Industrial Electronics Manufacturing Review, 2022.

Thompson, M.L. "Precision Measurement Techniques for Laminate Thickness Verification in Industrial Applications." Manufacturing Quality Assurance Quarterly, 2023.

Rodriguez, S.A. "Comparative Analysis of Substrate Material Tolerances in High-Performance Electronic Applications." Electronic Materials Science Journal, 2022.

Williams, D.P. "Procurement Best Practices for Engineered Composite Materials in B2B Manufacturing." Supply Chain Management Review, 2023.

Kumar, A.R. "Thermal and Mechanical Property Relationships in Thickness-Controlled Epoxy Glass Composites." Advanced Materials Processing, 2022.

Get a complete product list and quotation

J&Q New Composite Materials Company