Choosing the right suppliers and FR4 epoxy sheet material specs has a direct effect on the success of production and the long-term viability of the project. Knowing how the properties of a material, the abilities of a seller, and the needs of a project are related lets you make smart purchasing choices that improve both cost and performance.

FR4 Epoxy Sheet CNC Machining: Tools, Tips, and Tolerances

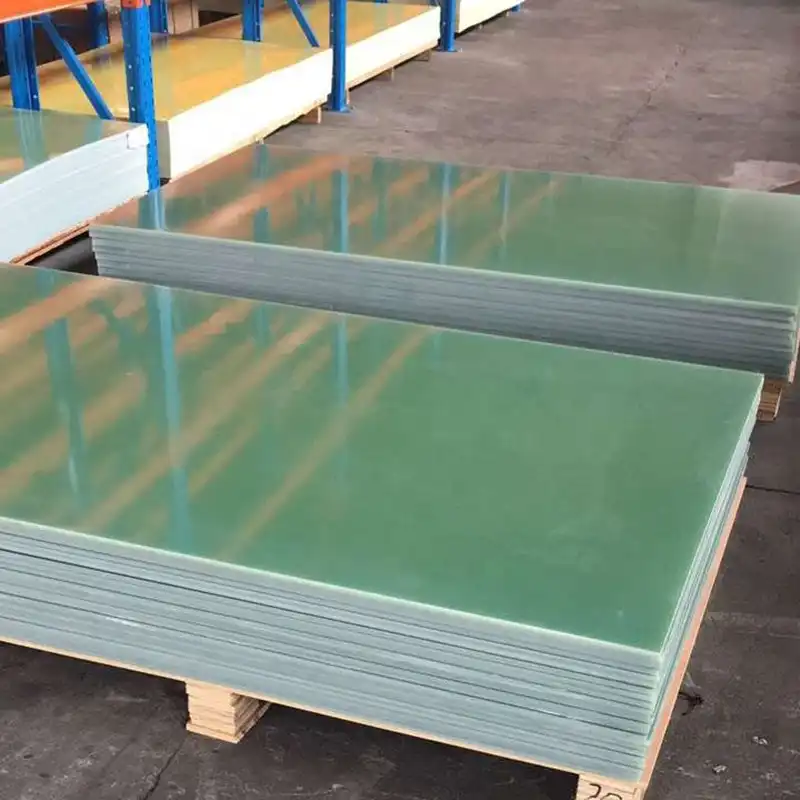

When it comes to precise making, FR4 epoxy sheet is one of the most useful composite materials used in modern industry. This fiberglass-reinforced epoxy laminate doesn't catch fire and is very strong. It also doesn't conduct electricity well, which makes it an essential tool for CNC machining in the automobile, electronics, and industrial sectors. Figuring out the right tools, methods, and tolerances for cutting these materials can have a big effect on the quality of the work and how efficiently things run in factories.

Understanding FR4 Epoxy Sheet CNC Machining

FR4 epoxy sheets are a high-tech composite material made from woven fiberglass cloth that has been mixed with epoxy resins. When these two things are put together, they make a material structure that has great mechanical properties and great electrical insulation properties. The label "FR4" on the material tells you that it doesn't catch fire and meets UL94 V-0 standards for flammability, which means it can be used in safety-critical situations.

Material Composition and Properties

Epoxy fiberglass sheets are made up of several layers of woven glass fabric that are joined together with thermosetting epoxy glue. This way of building makes a material that is very stable in terms of its shape over a wide range of temperatures. It can usually keep its shape from -40°C to +130°C while it is being used continuously. The glass transition temperature of good FR4 materials is usually higher than 170°C, which gives demanding uses a lot of thermal headroom.

The dielectric strength of these composite laminates is very high, often reaching 20 kV/mm. This makes them perfect for use as electrical insulation in power distribution systems and electronic assemblies. Because they don't absorb much water (usually less than 0.1% by weight), the electrical qualities stay the same even in damp working conditions.

CNC Machining Characteristics

Because the glass threads in epoxy resin sheets are rough, they make CNC machining tasks more difficult. Unlike homogeneous materials, these composites need special methods to keep them from delaminating, fibers pulling out, and resin spreading when they are cut. Because the material's properties aren't uniform, the settings for machining must take into account the fact that it behaves differently when cutting parallel to and perpendicular to fiber orientations.

Knowing how the material reacts to different cutting forces and temperatures is a big part of running a CNC machine well. When too much heat is applied, the epoxy matrix tends to soften, and the glass fibers can make tools wear out quickly if the cutting parameters are not set properly.

Essential CNC Tools and Equipment for Machining FR4 Epoxy Sheets

When working with fiberglass epoxy laminates, choosing the right tools is very important for getting good results. Because glass reinforcement is rough and epoxy resins change shape when heated, it's important to think carefully about the materials, shapes, and cutting factors of the tools used.

Cutting Tool Materials and Geometries

Carbide equipment is still the standard for working with epoxy glass materials because it doesn't wear down as quickly and keeps its cutting edges sharp. Although they cost a lot more at first, polycrystalline diamond (PCD) tools last longer and are better for high-volume production runs. PCD tools can make cutting edges that are very sharp, which lowers cutting forces and lowers the chance of delamination during grinding.

The shape of the tool is also very important to the success of machining. Cutting angles that are sharp, usually between 10 and 15 degrees, help lower cutting forces while still removing material cleanly. Spiral flute designs with improved chip evacuation paths stop material buildup that could damage the surface finish or lead to errors in the dimensions.

Machine Configuration and Setup

For most epoxy laminate jobs, CNC routers with high-frequency wheels that run between 18,000 and 24,000 RPM are the best way to cut the material. These high spinning speeds let you use tools with smaller diameters while still cutting at the right speed on the surface. Operators can find the best cutting settings for different material thicknesses and feature shapes by changing the speed.

To keep materials from deflecting during machining, workholding devices must apply even clamping pressure. Holding forces are spread out evenly across the surface of the material with vacuum table systems or specialized fixture plates with mechanical clamps. When working with thin FR4 epoxy sheets or making features close to the edges of the material, it's especially important to support it properly because areas that aren't supported could vibrate or chip.

Cooling and Lubrication Systems

Cooling techniques that work stop too much heat from building up, which can soften resin and load the tool. Compressed air cooling systems get rid of enough heat for most tasks and clear chips from the cutting zone at the same time. Mist cooling systems that use coolants that are based on water can improve the quality of the surface finish. However, care must be taken to keep the material from absorbing water, which could change their properties.

Expert Tips to Improve FR4 Epoxy Sheet CNC Machining Quality and Efficiency

When machining fiberglass-reinforced plastics, getting consistent, high-quality results involves paying attention to a lot of different process variables and using tried-and-true methods that have been developed over a lot of manufacturing experience. These methods deal with common problems and boost production efficiency at the same time.

Material Preparation and Handling

By inspecting the material properly before machining, you can avoid problems that cost a lot of money and get regular results every time. Any flaws that are easy to see, like holes, cracks, or uneven surfaces that could affect the quality of the cutting, should be found visually. The way materials are stored has a big effect on how easy they are to machine. For example, too much moisture absorption can make it hard to machine and cause the materials to lose their shape.

Temperature adaptation is another important thing to think about, especially when things have been stored in different kinds of environments. Allowing materials to reach room temperature before they are machined helps keep their shape and makes it easier to predict how they will behave during cutting.

Optimized Cutting Parameters

Feed rate optimization strikes a balance between the need for high output, a smooth surface, and long tool life. Too fast of feed rates can pull out fibers and make the surface rough, while too slow of feed rates can cause rubbing, which creates too much heat and spread of the resin. Based on what the industry knows, feed rates of 1.5 to 3.0 meters per minute are good starting points for most jobs. These rates can be changed depending on the type of material and the feature needs.

When choosing the depth of a cut, you need to think about how easily the material can separate, especially when making through-holes or edge features. Even though it takes longer, multiple shallow passes often give better results than aggressive single-pass processes. This method lowers the cutting pressure and the chance of damage below the surface that could affect the performance of the part.

Quality Monitoring and Process Control

Monitoring the state of cutting tools all the time helps keep the quality of machining consistent across production runs. By looking at the cutting edges visually between processes, you can find early signs of wear that could affect the surface finish or the accuracy of the measurements. Setting tool change intervals based on the amount of material being processed instead of random time periods makes sure that the tools work at their best.

Using standard measurement methods to check the surface finish gives you objective quality measures that can help you improve the process. Taking regular readings of roughness helps find process drift and lets you make changes ahead of time to keep quality standards.

Precision and Tolerances in FR4 Epoxy Sheet CNC Machining

Tight physical tolerances can only be reached with FR4 epoxy sheets that have good process controls and an understanding of how the material behaves. Because reinforced plastics are not uniform, they expand and shape differently when heated and when they are machined. This needs to be taken into account when making things with great accuracy.

Achievable Tolerance Ranges

With the right tools and settings, modern CNC machines can regularly achieve dimensional accuracy of ±0.1 mm for most feature shapes in epoxy fiberglass materials. Tolerances of ±0.05 mm can be reached for critical measurements that need them. This is possible with better quality control and process control. These abilities rely a lot on the thickness of the material, the complexity of the features, and how stable the environment is while the machine is working.

Because the material tends to fray fibers and chip edges, hole diameter standards are especially hard to meet. For holes bigger than 3 mm in diameter, hole tolerances can be kept to within ±0.025 mm by using specialized drilling methods and cutting tools that are sharp and well-supported. Because tools bend and are more sensitive to changes in the process, tolerances may need to be loosened for holes with a smaller diameter.

Factors Affecting Dimensional Accuracy

Differences in the amount of resin, the direction of the fibers, or the curing conditions can have a big effect on the limits that can be reached. When compared to cheaper options, high-quality materials from well-known brands usually show better consistency and allow for tighter tolerances.

Changes in the environment, like changes in temperature during cutting, can cause thermal expansion, which can affect the accuracy of measurements. Climate-controlled production environments help reduce these effects and allow consistent tolerance achievement even when the weather changes with the seasons.

Quality Control and Measurement Techniques

Coordinate measuring machines (CMM) are very accurate and can check that vital parts are within very small tolerances. These systems can find changes in dimensions that might not be obvious using normal measuring methods. Statistical methods for controlling a process help find patterns that could mean that the process is drifting or that tools are wearing out before quality problems happen.

Optical measurement tools can do quick inspections that work well in high-volume production settings where a full inspection may be needed. These non-contact measurement methods keep parts from getting damaged during checking and give detailed dimension data that can be used to improve the process.

Procurement Considerations: Buying FR4 Epoxy Sheets for CNC Machining Projects

Supplier Evaluation Criteria

When you buy from established suppliers whose quality control systems are written down, you can be more sure that the material properties will stay the same and that the delivery will go smoothly. ISO 9001 approval means that quality control is done in a planned way, which leads to more predictable material properties. Flame retardancy certification from UL makes sure that safety standards are met in many workplace settings.

Scalability and production capacity are important things to think about for projects that could grow or whose demand trends change. Suppliers whose manufacturing skills are flexible can meet changing needs while keeping quality standards high. Delivery times and costs may be affected by how close two places are to each other, especially for big orders or projects that need to be done quickly.

Material Specification and Grading

There are many standard types of epoxy glass that are easy to find and cheaper for most general-purpose uses. Figuring out how different grades of materials affect how well they work is important for finding the best balance between cost and function. Higher performance grades cost more, but they may have better mechanical qualities or be easier to machine, which makes the extra money worth it.

Material prices and machining needs are both affected by the thicknesses that are available and the tolerances that must be met. When it comes to price and availability, standard thickness options are usually better than custom specs. But starting with material that is closer to the final size can cut down on the time it takes to machine and improve the quality of the surface finish.

Supply Chain Management Strategies

When you work with the same supplier for a long time, you can usually get better prices, more reliable deliveries, and more technical help. Partnerships that are already in place make it easier to talk about changes to specifications, delivery times, and quality problems. Suppliers who know about the needs of a certain product can give useful advice on choosing materials and processing methods.

Strategies for managing inventory must weigh the costs of keeping things in stock against the chance of supply problems or price changes. Knowing normal lead times and minimum order quantities can help you keep your inventory at the right level and make sure that you have the materials you need for when you need them.

J&Q's FR4 Epoxy Sheet Solutions for Your CNC Machining Needs

Drawing from over two decades of experience in manufacturing and distributing insulating materials, we understand the critical requirements for successful CNC machining operations with epoxy glass laminates. Our comprehensive material expertise, combined with more than ten years of international trading experience, positions us to deliver solutions that meet the most demanding industrial applications.

Product Range and Capabilities

Our extensive inventory encompasses a complete range of epoxy fiberglass sheet thicknesses and grades specifically selected for CNC machining applications. Each material batch undergoes rigorous quality control testing to ensure consistent mechanical properties, dimensional stability, and electrical characteristics. This systematic approach to quality management enables predictable machining behavior and reliable component performance across diverse applications.

Beyond standard material offerings, our custom sizing capabilities allow procurement teams to optimize material utilization and reduce machining waste. Pre-cut blanks and dimensioned FR4 epoxy sheets can significantly reduce production cycle times while ensuring optimal material yield for specific component geometries.

Technical Support and Services

Our technical team provides comprehensive machining guidance covering tool selection, cutting parameters, and process optimization strategies. This expertise proves particularly valuable when transitioning between different material grades or implementing new manufacturing processes. We collaborate closely with engineering teams to address application-specific challenges and develop solutions that enhance both quality and efficiency.

Quality certifications including UL recognition and RoHS compliance documentation support customer requirements for regulated applications. Our systematic approach to documentation and traceability provides the audit trail necessary for quality management systems in critical industries.

Logistics and Supply Chain Excellence

Our integrated logistics capabilities, including our own transportation network, enable reliable delivery performance that supports just-in-time manufacturing strategies. This comprehensive supply chain control allows us to provide accurate delivery commitments and respond quickly to urgent requirements or schedule changes.

Competitive pricing structures combined with flexible minimum order quantities accommodate both prototype development and high-volume production requirements. Our established relationships with global trading partners enable efficient international shipping and documentation support for customers worldwide.

Conclusion

Successful CNC machining of epoxy glass composites requires careful attention to tool selection, cutting parameters, and process control methods. Understanding the unique characteristics of these materials enables manufacturing teams to achieve excellent surface finishes, tight dimensional tolerances, and reliable production outcomes. The combination of proper equipment, optimized techniques, and quality materials creates the foundation for efficient manufacturing operations that meet demanding industrial requirements across multiple sectors.

FAQs

What cutting speeds work best for machining epoxy fiberglass sheets?

Optimal cutting speeds typically range from 100-300 meters per minute surface speed, depending on tool diameter and material thickness. Higher speeds generally produce better surface finishes but may require more frequent tool changes. Spindle speeds between 18,000-24,000 RPM work well for most applications using carbide tooling.

How can I prevent delamination during drilling operations?

Sharp drill bits with proper point angles, adequate backing support, and controlled feed rates help prevent delamination. Using specialized drilling techniques such as peck drilling for deeper holes and ensuring proper workholding reduces cutting forces that contribute to layer separation.

What tolerance ranges are realistic for precision components?

Standard machining operations can achieve ±0.1 mm tolerances consistently, while critical dimensions may reach ±0.05 mm with careful process control. Hole tolerances within ±0.025 mm are achievable for diameters above 3 mm using proper drilling techniques and quality tooling.

Which tool materials provide the best performance for high-volume production?

Polycrystalline diamond (PCD) tools offer superior tool life for high-volume applications, though carbide tools provide excellent performance for moderate production volumes at lower initial costs. Diamond-coated carbide tools represent a middle ground between performance and cost considerations.

Contact J&Q for Premium FR4 Epoxy Sheet Solutions

J&Q combines decades of manufacturing expertise with comprehensive technical support to deliver exceptional epoxy fiberglass materials for your CNC machining projects. Our established supply chain capabilities and commitment to quality consistency make us your trusted FR4 epoxy sheet supplier for demanding industrial applications. Contact our technical team at info@jhd-material.com to discuss your specific requirements and discover how our materials and services can enhance your manufacturing success.

References

Society of Plastics Engineers. "Machining Guidelines for Fiber-Reinforced Thermoset Composites." SPE Technical Publication Series, 2019.

American Society for Testing and Materials. "Standard Test Methods for Properties of Electrical Insulating Materials." ASTM International Standards, 2020.

Institute of Electrical and Electronics Engineers. "Guide for Insulation Systems for Power Equipment." IEEE Standards Association, 2018.

Manufacturing Technology Association. "CNC Machining Best Practices for Composite Materials." Industrial Manufacturing Handbook, 2021.

International Organization for Standardization. "Quality Management Systems for Electrical Insulation Materials." ISO Technical Standards, 2019.

National Institute of Standards and Technology. "Precision Measurement Techniques for Composite Materials." NIST Technical Publication, 2020.

Get a complete product list and quotation

J&Q New Composite Materials Company