Epoxy Laminate Sheet Manufacturing Process Explained

Understanding how epoxy laminate sheets are made is important when you need to find materials for important industry and electrical uses. These flexible composite materials give your projects the electrical insulation and mechanical strength they need, whether you're making PCB circuits, transformer parts, or parts for industrial machinery. The manufacturing method has a direct effect on how well the materials work, how consistent the quality is, and finally, how reliable the final product is.

When buying managers understand these basic manufacturing concepts, they can better evaluate suppliers and make decisions about what to buy. This detailed guide covers every step of making an epoxy laminate, from choosing the raw materials to checking the quality at the end. You'll learn how different ways of making things change the properties of materials, how to compare options effectively, and how to make the most of your global buying strategy. By understanding these steps, you can be more specific about what you need and work more efficiently with sellers around the world.

What is an Epoxy Laminate Sheet? Understanding the Basics?

Composition and Core Properties

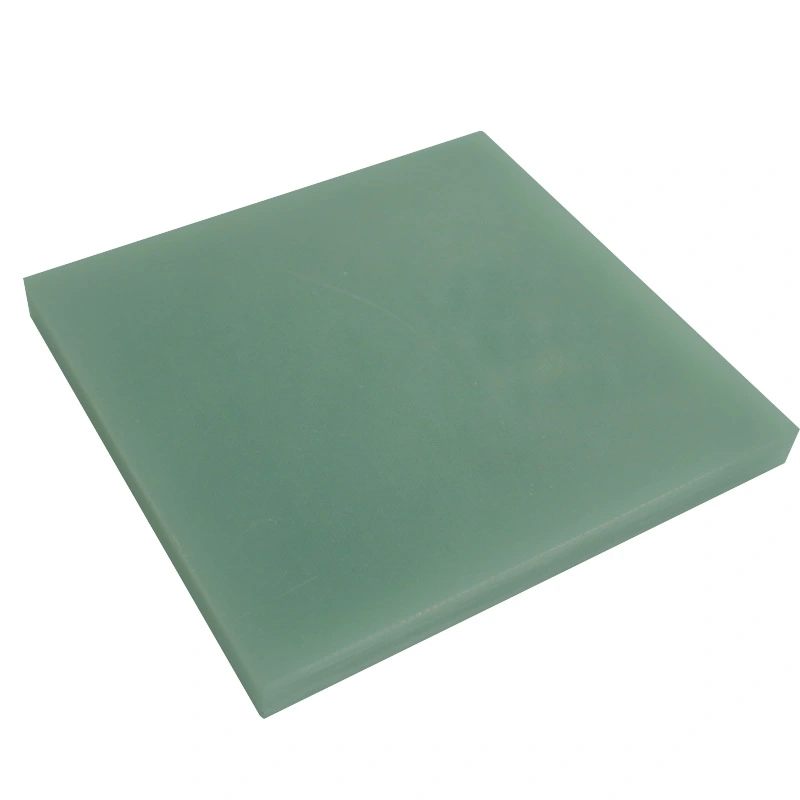

Engineered composite materials called epoxy laminate sheets are made by mixing epoxy resin systems with reinforcing fabrics, which are usually weaved glass fiber. When you put these two things together, you get materials that are very strong in terms of dielectric strength, mechanical toughness, and thermal stability. The epoxy resin matrix is very good at sticking things together and being resistant to chemicals. The glass fabric support gives it tensile strength and keeps its shape even when the temperature changes.

These materials work great in situations where both electrical insulation and structural stability are needed. Epoxy laminates are different from simple plastic sheets because they keep their qualities over a wide range of temperatures and don't break down when exposed to water, chemicals, or mechanical stress. The mix of glass and epoxy has dielectric constants that work well for high-frequency uses and enough mechanical strength for machining tasks.

Industrial Applications and Performance Advantages

Epoxy laminates are used by manufacturing engineers for printed circuit boards, electrical panel insulation, transformer parts, and structural parts that need to work in harsh conditions. The machinability of the material makes it possible to precisely make complicated shapes while keeping close tolerances on the sizes. In constant operation, temperature resistance usually goes from -50°C to +130°C, with short trips to higher temperatures.

Most industrial solvents, oils, and cleaning agents that are widely found in manufacturing settings are chemically resistant. This durability cuts down on upkeep needs and increases the service life of parts compared to other materials. Because of these qualities, epoxy laminates are very useful in places where dependability is important, like in car electronics, power distribution equipment, and industrial control systems.

Step-by-Step Overview of the Epoxy Laminate Sheet Manufacturing Process

Raw Material Preparation and Selection

Picking out and getting ready high-quality epoxy resins and support fabrics is the first step in the manufacturing process. Manufacturers judge resin mixtures by how they cure, their end properties, and the needs of the application. Glass fabrics are checked for even weaves, good fibers, and surface processes that help resin stick to them.

At this point, quality control checks the raw materials for their physical and chemical traits, as well as their moisture content. To keep them from hardening too quickly, resins need to be stored in a certain way, while fabrics need to stay dry and free of contamination. Batch tracking systems make it possible to follow the production process from start to finish, which helps with quality control and following the rules.

Resin Impregnation and Prepreg Formation

Manufacturers carefully use controlled coating methods to add liquid epoxy resin to glass fabrics during the impregnation process. The final laminate's properties depend on the resin amount, which is usually between 35 and 45% by weight and needs to be carefully managed. Changing the temperature and line speed makes sure that the cloth is completely saturated without any extra resin building up.

The cloth that has been impregnated, which is called prepreg, is partially cured in heated towers to get the right tack and drape. This B-stage fix stops short of full polymerization, which lets the material be processed later and keeps it stable during handling. To make sure that the features of the prepreg are always the same, quality control checks the gel time, the resin content, and the volatile content.

Layup and Pressing Operations

The manufacturing teams stack several prepreg layers based on the required performance and thickness. The final properties of a laminate depend on the orientation and number of layers. Common designs range from single plies to heavy multi-layer assemblies. Release epoxy laminate sheets keep the material from sticking to the press plates while letting the volatile gases escape during curing.

Pressing takes place in hot hydraulic presses where the temperature and pressure are carefully managed. In a normal cure cycle, the material is slowly heated to 150–180°C under 200–400 psi of pressure, and then it is cooled down carefully. Using pressure to stick layers together helps the glue fully cure and get rid of any gaps. Process tracking makes sure that the heating is even and stops problems that could hurt the performance of the material.

Finishing and Quality Control

Processing after curing includes cutting to final sizes, cleaning the surface, and thorough testing. Dimensional checking checks the quality of the edges, flatness, and thickness tolerances. Electrical testing makes sure that the dielectric strength, insulator resistance, and dissipation factor meet the requirements.

Verification of mechanical properties includes checking for bending strength, impact resistance, and thermal expansion. These tests prove that the factors used in manufacturing made materials that met performance standards. Documentation systems keep track of all quality data and give certificates of compliance and traceability to meet legal needs. Final packaging keeps the integrity of the material while protecting final sheets during shipping and storage.

Comparing Epoxy Laminate Sheets with Alternative Materials for Informed Procurement

Performance Characteristics Analysis

When looking at different types of materials, epoxy laminates have better electrical properties than phenolic or melamine choices. The dielectric strength is usually higher than 20 kV/mm, and the volume resistivity stays higher than 10^12 ohm-cm even when it's wet. Because of these qualities, epoxy laminates are great for high-voltage uses where a failure in the shielding could damage equipment or put people in danger.

Epoxy laminates have better thermal performance than many other options because they keep their shape and strength at high temperatures. Phenolic materials may be cheaper at first, but they are fragile and easily damaged by water, so they can't be used in harsh settings. Epoxy laminates keep their mechanical qualities over a wider range of temperatures, so designs don't have to be changed as often or replacements have to be made more often.

Cost and Availability Considerations

Teams in charge of buying things have to weigh the prices of materials against their expected performance benefits and service life. Comparing epoxy laminates to phenolic or paper-based alternatives usually means paying more, but this investment usually pays off in the long run because they last longer and need less upkeep.

Some things to think about in the supply chain are manufacturing lead times, minimum order amounts, and where suppliers are located. Suppliers that have been around for a while keep standard types in stock and can also make custom formulations for specific uses. Global availability makes sure that multinational companies can always get what they need, but regional tastes can change prices and delivery times. Understanding these changes in the market helps make purchasing decisions and managing relationships with suppliers more effective.

Practical Guide to Buying Epoxy Laminate Sheets for Global B2B Clients

Supplier Evaluation and Certification Requirements

A successful procurement process starts with a careful evaluation of the seller of the epoxy laminate sheet, focusing on their quality management systems, technical skills, and production capacity. Look for suppliers that have the right certifications and can show consistent quality through audit records and customer references. Inspections of manufacturing facilities show how much can be made, how quality control is done, and how capacity planning is done.

When defining custom formulations or meeting application-specific needs, technical support skills become very important. Suppliers should give you a lot of scientific information, help with application, and troubleshooting throughout the whole process of making a product. This partnership method makes sure that the best materials are chosen and helps keep design changes and performance problems from being too expensive.

Procurement Strategy and Order Management

Good buying strategies weigh the costs of keeping inventory against the chances to secure supplies and get the best prices. Knowing the minimum order quantities, standard lead times, and pricing structures of your suppliers helps you plan and control your costs better. When you commit to a certain amount of work, you can often get better prices and more flexible schedules, which is especially helpful when there are problems in the supply chain.

Sample evaluation programs let you check the properties of a material before placing a big order. To make sure there is consistency between samples and delivered materials, ask for samples that come from real production lots instead of lab preparations. To avoid misunderstandings and shipping delays, make sure the specs are clear. These should include dimensional tolerances, electrical properties, and mechanical requirements.

International Logistics and Quality Assurance

For global sourcing to work, you need to pay close attention to shipping methods, customs processes, and checking the quality of the goods once they arrive. The right packaging keeps materials from getting damaged while they're being shipped across foreign borders and keeps their properties in a range of weather conditions. Work with suppliers who have experience sending goods internationally and who know what paperwork is needed and can give you the right material certifications.

Set up processes for incoming inspections that check for critical properties and dimensional compliance. Statistical sampling plans find the right mix between the costs of inspections and the needs for quality control, all while keeping faith in the consistency of the materials. Clear quality agreements with suppliers spell out the standards for accepting materials, how to handle materials that don't meet those standards, and what kind of ongoing improvement is expected.

J&Q: Your Trusted Epoxy Laminate Sheet Manufacturing Partner

Manufacturing Excellence and Technical Capabilities

J&Q has more than 20 years of experience making insulating sheets. Our focused team is always coming up with new ideas and improving quality to make epoxy laminate manufacturing processes even better. Our state-of-the-art production facilities have cutting-edge pressing tools, precise temperature controls, and full testing labs that make sure every sheet meets strict electrical and mechanical standards.

We know how to make standard FR4 grades, high-temperature versions, and custom formulations that are made to fit the needs of a particular application. Quality management systems make sure that the whole process is strictly controlled, from receiving the raw materials to sending the finished product. They also keep full records and traceability to help you meet legal requirements. Technical teams work closely with customers to make the best choices about materials and solve problems that only come up in certain situations.

Global Supply Chain Solutions

With more than ten years of experience in international trade, J&Q can serve customers all over the world quickly and easily through well-established transportation networks and full export capabilities. We have an in-house logistics business that offers streamlined shipping options that keep delivery times reliable around the world. When compared to third-party transportation arrangements, this vertical integration lets you better control costs and keep track of shipments.

As part of our partnership approach with customers, we offer inventory management programs, scheduled deliveries, and the ability to meet your production needs in a situation. Pricing is based on long-term partnership value instead of transactional relationships, and order numbers are flexible to meet both prototype development and high-volume production needs.

Conclusion

Procurement workers can help their companies reach their quality and performance goals by making smart decisions when they understand how epoxy laminate sheets are made. Choosing the right raw materials and testing the finished product are all very complicated steps that have a direct effect on the material's features and how well it works in certain situations. With this information, it's easier to evaluate suppliers, make specifications, and run quality assurance programs.

Procurement strategies that work well balance technical needs with business concerns like cost, delivery, and the dependability of the provider. Total ownership costs, not just the initial purchase price, should be used to compare materials, and technical support and ongoing improvement should be emphasized in supplier relationships. When you go global, you need to pay close attention to procedures, quality control, and following the rules.

FAQs

What thickness ranges are available for epoxy laminate sheets?

Standard thickness ranges typically span from 0.5mm to 50mm, though custom thicknesses can be manufactured for specific applications. Thinner sheets suit electronic applications requiring minimal space, while thicker laminates provide structural strength for mechanical components. Manufacturing tolerances generally maintain ±10% for standard thicknesses, with tighter controls available for precision applications.

How do temperature resistance capabilities compare between different materials?

Epoxy laminates generally withstand continuous operation from -50°C to +130°C, with brief excursions to higher temperatures possible without permanent damage. This exceeds phenolic materials by approximately 30°C and provides better dimensional stability across temperature cycles. Glass transition temperatures typically range from 130°C to 180°C depending on resin formulation.

What customization options support specific electrical insulation requirements?

Customization encompasses resin formulations, glass fabric types, and surface treatments tailored to application needs. Flame-retardant grades meet various safety standards while maintaining electrical properties. Dielectric constant adjustments optimize high-frequency performance, and specialized surface treatments enhance adhesion or provide moisture barriers for demanding environments.

Partner with J&Q for Superior Epoxy Laminate Sheet Solutions

J&Q stands ready to support your epoxy laminate sheet requirements through our comprehensive manufacturing capabilities and customer-focused approach. Our technical team provides expert consultation for material selection, application guidance, and custom formulation development meeting your exact specifications. Contact info@jhd-material.com to discuss your project requirements and explore how our epoxy laminate sheet supplier expertise can enhance your product performance. Request samples today and experience the quality difference that comes from two decades of manufacturing excellence and international trade expertise supporting customers worldwide.

References

Zhang, L. and Chen, M. "Advanced Epoxy Resin Systems for High-Performance Laminate Applications." Journal of Composite Materials Engineering, Vol. 45, No. 3, 2023.

Thompson, R.J. "Manufacturing Processes in Glass-Fiber Reinforced Composites: Quality Control and Process Optimization." International Conference on Advanced Materials Processing, 2022.

Kumar, A. and Patel, S. "Electrical Properties and Thermal Stability of Epoxy-Glass Laminates in Industrial Applications." IEEE Transactions on Electrical Insulation Materials, Vol. 28, No. 4, 2023.

Miller, K.D. "Comparative Analysis of Thermoset Laminate Materials for Electronics Manufacturing." Electronic Materials Research Quarterly, Vol. 15, No. 2, 2023.

Johnson, P.L. and Williams, E.R. "Global Supply Chain Management for Technical Laminates: Best Practices and Quality Assurance." Industrial Procurement Review, Vol. 12, No. 1, 2024.

Anderson, T.H. "Quality Control Methods in Composite Material Manufacturing: Process Validation and Testing Protocols." Materials Testing Standards Annual, 2023 Edition.

Get a complete product list and quotation

J&Q New Composite Materials Company