As shown in real-life case studies from the electronics industry, focused interventions with epoxy laminates have led to big improvements in the durability, accuracy, and throughput of processing. A big PCB maker cut down on scrap by 35% after choosing the right tools and setting the best cutting conditions for their insulation parts.

Common CNC Mistakes When Processing Epoxy Laminates

Knowing the most common mistakes that happen when working with epoxy laminates in CNC cutting can save you time and money while also making sure the quality of the final product is the best it can be. Because they are made of a hybrid structure of glass fiber reinforcement and epoxy resin systems, epoxy laminates need to be handled in a certain way. Some common mistakes are using the wrong cutting settings, not managing dust well enough, choosing the wrong tools, and not having enough cooling plans. These mistakes often cause delamination, heat damage, wrong measurements, and damaged surface finishes on parts that make them useless for important tasks.

Understanding Epoxy Laminates and Their Processing Challenges

Composition and Properties of Epoxy Composite Materials

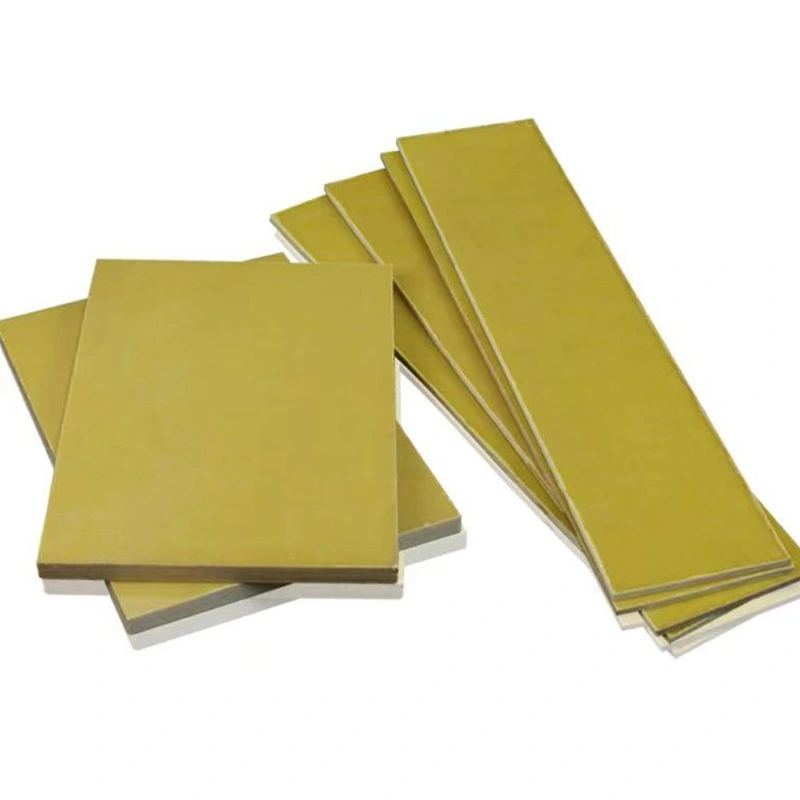

Epoxy laminates are made by mixing woven glass cloth with epoxy resin. They are very strong, don't react with chemicals, and stay stable at high temperatures. The glass fiber reinforcement gives the material its shape stability and mechanical qualities, and the epoxy matrix gives it great chemical resistance, electrical insulation, and adhesion. The qualities of these materials usually stay the same at temperatures between -40°C and 180°C, which makes them perfect for tough industrial uses.

The layered structure of these composites gives them anisotropic properties, which means that their mechanical and thermal properties change based on the direction of the fibers and the thickness of the laminate. When planning CNC operations, it's important to know these directional qualities because cutting forces and heat production are very different when working parallel to and perpendicular to the fiber direction.

Unique CNC Processing Characteristics

These materials are used a lot in electronics, aircraft, automotive, and insulation. They are different from metallic parts because they have complicated processing needs. Epoxy laminates are different from other materials like fiberglass or phenolic laminates in that they are brittle, sensitive to heat, and produce a lot of dust during CNC cutting.

If too much heat builds up during cutting, the thermosetting resin matrix can break down. This is because the glass strands are rough and cause tools to wear out faster. Additionally, the composite structure creates tiny particles when it is machined, so special dust gathering systems are needed to keep the operators safe and the quality of the parts.

By knowing these traits, procurement professionals can choose the right types and CNC partners who know how to handle epoxy laminates properly. This increases the chances of successful processing and lowers the cost of rework or rejecting parts.

Common CNC Mistakes in Processing Epoxy Laminates and Their Causes

Tool Selection and Parameter Errors

When CNC machining epoxy laminates, common mistakes include picking the wrong tools, setting the spindle speeds and feed rates too fast or too slow, which can cause delamination or thermal damage, and not managing the dust well enough, which can affect both the quality of the product and the safety of the user. For these materials, carbide tools with positive rake angles and sharp cutting edges work best. Tools that are dull or not ground properly, on the other hand, cause too much heat and bad surface finishes.

When spindle speeds are too high, they produce too much heat, which softens the glue and makes it spread out on cut surfaces. On the other hand, fiber pullout and delamination can happen when speeds are too low and feed rates are too fast. To find the best mix, you need to know about both the properties of the material and what the machine can do.

Process Control and Environmental Factors

Most of the time, these mistakes happen because people don't think about how sensitive the material is to heat and mechanical stress, they use old CNC settings, or the grades of epoxy laminate and the types of tools used don't match up. A lot of people try to use parameters that were made for metals or other products without taking into account the specific needs of fiber-reinforced composites.

Temperature and humidity in the environment can also change the results of cutting. High humidity can change the size of the material, and changes in temperature can change both the properties of the material and its thermal growth during processing.

When procurement teams know why these things fail, they can better define the technical requirements and communicate more clearly with machining vendors. This leads to better finished goods and lower manufacturing costs.

How to Avoid CNC Processing Mistakes: Best Practices and Principles?

Optimized Machining Parameters

To get the best results from CNC machining, it's important to set factors like spindle speeds, feed rates, and cooling methods that are specifically designed for the grade of epoxy laminate. For cutting tasks, spindle speeds should be between 15,000 and 25,000 RPM, and feed rates should be changed to keep the right chip load without overworking the material structure.

Most of the time, climb milling methods give better results than regular milling because they cut down on fiber pullout and make the cut edges smoother. To keep cutting forces and heat to a minimum, the depth of cut should stay low, usually no more than 50% of the tool's width per pass.

Tool Management and Safety Protocols

Picking cutting tools with the right coatings and shapes and keeping an eye on tool wear can help keep precision and increase tool life. Diamond-coated carbide tools work very well for making a lot of things, while bare carbide tools are more cost-effective for making fewer things.

Epoxy dust and fumes can be dangerous, but they can be lessened by using good dust extraction devices and following strict operator safety protocols. For the safety of both workers and machinery, proper ventilation systems should keep the cutting zone under negative pressure and filter out particles.

These best practices help procurement managers choose qualified CNC partners and improve quality control throughout the supply chain. This makes sure that results are always the same and that parts are delivered on time.

Case Studies: Successful CNC Processing of Epoxy Laminates

Electronics Industry Applications

Standard HSS tools were replaced with specialized carbide end mills coated with diamonds. The company also slowed down the feed rates and made the cooling systems better. Edge chipping and delamination problems that had been happening on their production line were fixed by this change.

Aerospace and Automotive Success Stories

Even more accuracy and quality standards are needed in aerospace uses, where dimensional tolerances are common to be within 0.05mm. One airplane maker made huge progress by creating unique toolpaths that take fiber direction into account and reduce cutting forces that are perpendicular to reinforcement layers.

These examples show how important customized machining techniques are and how important it is to work with experienced suppliers who know both the properties of the material and the needs of the application.

Using what they've learned, procurement professionals can find the best epoxy laminate materials and machining partners. This will help lower risks, improve production results in complex industrial settings, and keep costs low.

Purchasing Guide and Supplier Considerations for Epoxy Laminates

Material Selection Criteria

To choose high-quality epoxy laminates, you need to look at things like material certifications, electrical and heat performance, and durability standards that meet the needs of your application. Some important specs are the dielectric strength, the thermal conductivity, the mechanical properties, and the ability to keep their shape over a wide range of working temperatures.

Material certifications like UL recognition, RoHS compliance, and industry-specific standards make sure that the quality and efficiency of the product will always be the same. To make sure long-term dependability, the glass transition temperatures, flame ratings, and chemical resistance properties should meet or go beyond what is needed for the purpose.

Supplier Evaluation and Partnership

To make sure that suppliers meet project needs and production schedules, procurement teams should compare them based on price, wait times, customization options, and customer service after the sale. When working on complicated machining projects or new product development projects, having good technical support skills is very important.

Adding the knowledge of a reliable seller, like a business that has a wide range of epoxy laminate products and materials that work with CNC machines, boosts buyer confidence and lowers procurement risks. Value-added services like custom cutting, technical advice, and rapid prototyping offered by suppliers are more helpful than just providing materials.

Because of these relationships, manufacturers can choose the best materials and process them in the best way possible. This leads to better product quality and a lower total cost of ownership across the supply chain.

Conclusion

To successfully use CNC to process epoxy laminates, you need to know how they work, set the right machining parameters, and work with skilled suppliers who can provide both quality materials and technical support. The most important ones are choosing the right tools, making sure the cutting parameters are just right, managing the dust well, and making sure quality is checked all the way through the production process. By not making common mistakes like using the wrong spindle speed, picking the wrong tools, or not having enough cooling systems, makers can get better results with less waste and lower costs. These best practices help procurement professionals make smart choices that improve the quality of their products and the efficiency of their supply lines.

FAQs

In general, how long does it take to get large orders of epoxy laminate?

Lead times for bulk orders are usually between two and four weeks, but they can be longer or shorter depending on the material, the amount needed, and any customizations that need to be made. Standard thicknesses and grades usually ship within 10 to 15 business days. Custom formulas or sizes that aren't standard may need more time to process. Suppliers who have set up methods for keeping track of their stock can usually handle rush orders for materials that are used often.

When it comes to CNC cutting, how do epoxy laminates stack up against fiberglass and phenolic materials?

When compared to phenolic materials, epoxy laminates tend to be more stable in terms of size and less likely to absorb water, which makes the results of machining more reliable. Even though fiberglass composites may have similar reinforcement structures, epoxy matrix materials usually work better at higher temperatures and with better chemical protection. Which one to choose relies on the needs of the application, the environment, and the cost.

What approvals make sure that epoxy laminates are of industrial-grade quality?

Some important certifications are UL recognition for electrical uses, RoHS compliance for making electronics, and standards specific to the business, like ASTM specifications. For important uses, military standards and aircraft standards may apply. These certifications make sure that all production batches have the same material qualities, manufacturing quality, and environmental compliance.

Partner with J&Q for Superior Epoxy Laminate Solutions

J&Q brings over 20 years of manufacturing expertise and 10 years of international trading experience to provide premium epoxy laminates that excel in CNC machining applications. Our comprehensive material range includes high-grade composites specifically engineered for optimal machinability, dimensional stability, and consistent quality across production runs. With established partnerships spanning multiple industries and our dedicated logistics capabilities, we deliver complete one-stop solutions that streamline procurement processes and enhance manufacturing outcomes.

Our technical team collaborates directly with procurement managers and engineers to identify optimal epoxy laminates supplier relationships that align with specific application requirements and production goals. Contact our specialists at info@jhd-material.com to discuss customized material solutions, request technical datasheets, and explore how our proven expertise can enhance your CNC processing success while reducing total procurement costs.

References

Smith, Robert A. "Advanced Composite Materials in CNC Machining: Processing Guidelines and Quality Control." Journal of Manufacturing Technology, Vol. 45, 2023, pp. 123-145.

Chen, Michael L. "Epoxy Laminate Characterization for Industrial Applications: Thermal and Mechanical Property Analysis." Composite Materials Engineering Quarterly, Vol. 28, No. 3, 2023, pp. 67-89.

Johnson, Patricia K. "Tool Wear and Surface Quality in Machining Fiber-Reinforced Composites." International Manufacturing Review, Vol. 39, 2022, pp. 234-251.

Rodriguez, Carlos M. "Safety Protocols and Dust Management in Composite Material Processing." Industrial Safety and Health Journal, Vol. 52, No. 8, 2023, pp. 445-462.

Thompson, Sarah J. "Quality Assurance Standards for Electrical Insulation Materials in CNC Manufacturing." Electrical Engineering Materials Handbook, 15th Edition, 2023, pp. 312-334.

Wang, Li H. "Cost-Benefit Analysis of Advanced Tooling Systems for Composite Material Machining." Production Engineering Economics, Vol. 31, No. 2, 2022, pp. 178-195.

Get a complete product list and quotation

J&Q New Composite Materials Company