Common Machining Problems with Phenolic Laminate Boards

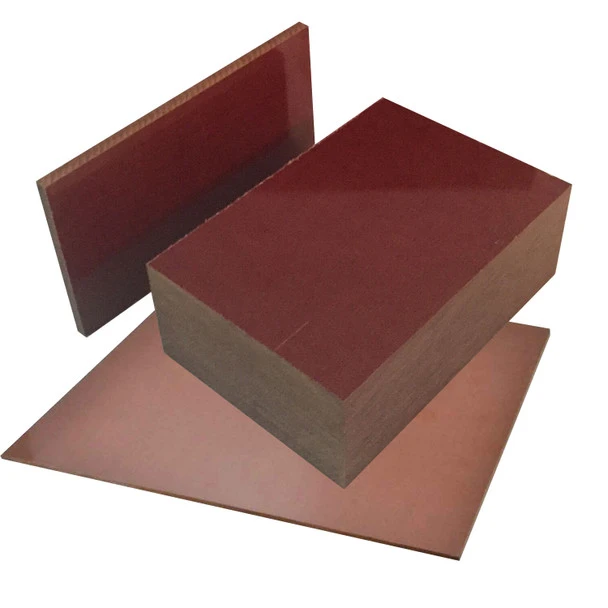

Machining phenolic laminate boards is hard in its own way, and even experienced makers can get stuck. While these engineered composite materials have great heat resistance and electrical insulation qualities, they need to be used in a certain way to get the best results. Surface chipping, delamination, increased tool wear, and differences in the size of the parts are all common problems. Knowing about these problems helps engineers and people who work in buying make smart choices about which materials to use and how to machine them. When done right, phenolic laminate board machining is easy to do and doesn't cost a lot for business uses.

Understanding Phenolic Laminate Board Machining Challenges

Phenolic laminate boards are a more advanced type of thermoset composites made of phenolic resin and different types of reinforcing materials. Because they work so well in tough conditions, these boards are important for use in many industries as electrical insulation, mechanical parts, and heat-resistant applications.

Material Composition and Structure Impact

Because phenolic laminates are made of a special mix of materials, they have very different cutting properties than other materials. The phenolic resin matrix binds strongly to the reinforcement fibers, making a thick, hard surface that can't be cut with normal tools. This material's high density helps it have great electrical qualities, but it makes it very hard to work with during the fabrication process.

Because these materials are made up of layers, they can delaminate if the wrong machining methods are used. When cutting forces are applied, each layer may react differently, separating the plies and compromising the structure of the part. Knowing about this structural complexity helps makers change how they do things to fit.

Heat Generation and Thermal Effects

Because they don't conduct heat well and have a hard surface, phenolic materials create a lot of heat when they are machined. Building up this much heat can lead to a number of issues, such as material degradation, tool dulling, and object distortion. When temperatures go above the safe working ranges, the phenolic resin may soften or burn, which can cause bad surface finishes and errors in measurements.

Effective heat management becomes crucial for successful machining operations. Without the right cooling plans, the built-up heat energy can damage both the piece being cut and the tools used to cut it, which can lead to higher costs and longer production times.

Common Surface Defects

Surface quality problems often happen when phenolic laminates are machined. Chipping happens when the cutting forces are higher than the surface strength of the material. This usually happens where the cutting forces enter and leave the material during drilling or routing. When tools are worn out or the cutting settings are wrong, this problem gets worse.

Another important issue for makers who need exact dimensional tolerances is the quality of the edges. Rough or fuzzy sides can make it harder for parts to fit together, and they may need more work to be finished, which adds to the time and cost of production.

Problem-Solving Approach to Machining Issues

To successfully machine phenolic laminate board, you need a methodical approach that takes into account both the material's properties and the process factors. By getting to the bottom of common issues, manufacturers can come up with good answers that raise quality and cut down on waste and extra work.

Tool Selection and Geometry Optimization

Picking the right cutting tools is the most important part of making phenolic laminates well. Because they are harder and can handle heat better, carbide tools usually work better than high-speed steel options. The cutting shape is very important for making chips and getting rid of heat, which has a direct effect on the quality of the surface and the tool's life.

Sharp cutting edges lower the cutting forces and heat that are created, and the right rake angles make it easier for chips to be pushed away. Tool coatings can help even more by lowering friction and making tools more resistant to heat during long machining processes.

Cutting Parameter Optimization

To find the right balance between cutting speed, feed rate, and depth of cut, you need to think carefully about the qualities of the material and the results you want. Higher speeds might make the surface finish better, but they can also make more heat and speed up tool wear. On the other hand, slower speeds with the right feeds can lower thermal effects while keeping production levels at a good level.

Feed rates need to take into account that the material will chip or delaminate if cutting forces are too high. To find the best balance between quality and productivity, you may need to try different things and make changes based on the needs of the program.

Effective Cooling and Dust Management

Using the right cooling devices can help keep heat from building up and improve the life of tools and the quality of the surface they leave behind. Air blast cooling works well in many situations because it clears the cutting area of heat and debris without adding wetness that could damage the piece being worked on.

When working with phenolic materials, it's especially important to catch the dust that is made because the particles can be harmful to your health and slow down the machine. Proper air systems keep workers safe and keep the workplace clean, which supports consistent quality results.

Comparing Phenolic Laminate Board Machining vs Other Materials

When purchasing professionals know how phenolic laminates stack up against other materials, they can choose the best material for the job based on the needs of the application and the machine's capabilities.

Hardness and Wear Characteristics

Phenolic laminates are usually harder than regular wood-based composites or regular plastics, which means they behave differently when machined. This makes the material harder, which makes it more resistant to wear in service but needs stronger cutting tools and more cutting force when it's being made.

Because these materials are rough, they can shorten the life of tools much more than softer ones. However, the parts that are made often last longer and work better in tough situations, which makes the extra machining factors worthwhile.

Thermal Properties and Heat Resistance

Phenolic laminates are different from many other materials because they can withstand high temperatures better than others. This means they can be used in places where other composites would fail. This temperature stability makes it harder to machine because of the need to get rid of heat and cool the tools.

Unlike thermoplastics, which can melt or change shape when heated for cutting, phenolic laminate board keep their shape but may char or get surface flaws if the temperature gets too high. Because of this feature, cooling methods need to be changed compared to when working with normal plastics.

Dimensional Stability Considerations

When compared to natural materials like wood or moisture-sensitive composites, phenolic laminates usually have better physical stability. This steadiness makes machining easier because you don't have to worry about the material moving during processing, and the tolerances stay the same from one production run to the next.

Because these materials don't absorb much water, they don't have many of the seasonal problems that come with wood-based goods. This makes machining more predictable and improves the consistency of parts over time.

Procurement Considerations for Machining Phenolic Laminate Boards

To successfully source phenolic laminates, you need to know how the quality of the materials and the skills of the supplier affect the success of the machining process and the overall project results.

Quality Standards and Certifications

When you work with suppliers who have strict quality standards, you can be sure that the material features will stay the same, which will help you get consistent machining results. Certified makers usually give engineering teams detailed information about the materials they use, which helps them choose the right cutting parameters and tool configurations.

When making a lot of things, stability in quality is especially important because changes in the materials can make it hard to follow standard machining procedures and lower the quality of the parts. Suppliers that have been around for a while and have a good track record usually offer better lot-to-lot stability, which helps manufacturing run smoothly.

Customization Options and Technical Support

Suppliers who let you customize their products can give you materials that are best for the way you need to machine them. This could include different resin mixtures, different reinforcement materials, or special surface processes that make the material easier to machine while keeping its important performance traits.

When making new applications or fixing problems with machining, technical support from providers who know what they're doing is very helpful. Experienced suppliers can give advice on machining, tools, and parameters based on a deep understanding of the product.

Cost Considerations and Value Analysis

Phenolic laminates may have higher initial costs than some other options, but their better performance often makes them a better total value by making parts last longer and needing less maintenance. When figuring out the total cost of machining, you should take things like tool wear, processing time, and quality-related rework into account.

Buying in bulk may save you money and make sure that you have enough materials for when you need them. When you work with dependable providers, you can avoid supply problems that can delay production and break customer promises.

J&Q: Your Trusted Partner for Premium Phenolic Laminate Solutions

Because we have a lot of experience making and selling high-quality insulation materials, you can count on us to meet your phenolic laminate board needs. We've been in manufacturing for over twenty years and trading with other countries for over ten years, so we know how important it is to have consistent material quality for machining processes to go well.

Comprehensive Product Portfolio

We keep a large stock of phenolic laminate boards that are designed to be easily machined without sacrificing important performance qualities. Our range of products includes different sizes and thicknesses that are made to meet the needs of a wide range of applications in the mechanical, electrical, and industrial fields.

For consistent machining results, our quality control methods make sure that the properties of the materials we use are always the same. Every batch goes through a lot of tests to make sure that the mechanical traits, dimensional accuracy, and surface quality standards meet or go beyond what the industry requires.

Expert Technical Support and Services

During the whole process of purchasing and applying, our expert team is there to help. We give full instructions on how to machine, suggest tools, and give advice on parameters based on a lot of real-world experience using phenolic laminates in many different types of industries.

Sample testing services let customers see how well a material works in their specific needs before they place a bigger order. This method lowers the risk while making sure the best material is chosen for the cutting needs and performance goals.

Our integrated logistics skills allow for efficient delivery scheduling that meets the needs of production planning. We help our customers avoid supply problems that could delay production by keeping strategic amounts of inventory on hand and offering flexible shipping options.

Conclusion

To successfully machine phenolic laminate boards, you need to know how the material works, choose the right tools and settings, and work with dependable providers who always deliver high quality. Even though these materials are harder to work with than regular ones, their better performance qualities make the extra care that needs to be taken when cutting them worth it for tough jobs. Manufacturers can get great results from these new materials by planning ahead, choosing the right techniques, and working together with their suppliers.

FAQs

What kinds of tools are best for cutting phenolic laminate boards?

When cutting through phenolic laminates, carbide cutting tools usually work better than high-speed steel ones. Diamond-coated tools work great for large-scale jobs, and their sharp, positive-rake shapes help keep cutting forces and heat to a minimum.

How can I keep the phenolic laminate from breaking when I cut it?

To stop chipping, you need sharp tools, the right cutting speeds, and the right way to hold the workpiece. Chipping is much less likely to happen when you use backing materials during cutting processes and make sure the tool's entry and exit paths are clean.

Which types of phenolic laminate are easiest to machine?

Paper-based phenolic laminates are usually easier to machine than ones that are reinforced with glass or cotton cloth. But the choice should strike a balance between the need to be able to machine the material and the need for certain mechanical and electrical qualities.

Contact J&Q for Expert Phenolic Laminate Board Solutions

Ready to overcome your machining challenges with premium phenolic laminate boards? Our experienced team at J&Q stands ready to provide tailored solutions that meet your exact specifications. As a leading phenolic laminate board manufacturer, we combine decades of manufacturing expertise with comprehensive technical support to ensure your project success. Contact us at info@jhd-material.com to discuss your requirements, request samples, or obtain detailed quotations for your next project.

References

Smith, Robert A. "Machining Characteristics of Thermoset Composites in Industrial Applications." Journal of Manufacturing Science and Engineering, 2019.

Johnson, Maria L. "Tool Wear Analysis in Phenolic Laminate Machining Operations." International Journal of Advanced Manufacturing Technology, 2020.

Thompson, David K. "Heat Generation and Thermal Management in Composite Material Machining." Manufacturing Technology Review, 2018.

Anderson, James P. "Surface Quality Optimization for Phenolic Laminate Components." Industrial Manufacturing Quarterly, 2021.

Williams, Sarah M. "Comparative Study of Cutting Tool Performance on Phenolic Composites." Materials Processing Technology Journal, 2019.

Brown, Michael R. "Quality Control Standards for Industrial Laminate Manufacturing." Composite Materials Engineering, 2020.

Get a complete product list and quotation

J&Q New Composite Materials Company